Storage Planning

Master the essentials of storage planning with MH USA!

Chapter 6 : Floor Loading Considerations

When planning a mobile storage system, understanding floor loading is crucial. Structural engineers evaluate the overall weight load to ensure the floor can safely support a mobile system’s weight. This chapter explores how to calculate pounds per square foot and line load, as well as reinforcement and seismic anchoring options.

Calculating Pounds Per Square Foot

Traditionally, structural engineers calculate floor loading by determining the weight of the entire storage system, including carriages, shelving, media, and rails, and then dividing this by the total square footage of the installation space. This method is typically used for stationary storage, such as:

- Lateral Filing Cabinets

- Static Shelving

- Rotary Cabinets

By calculating the pounds per square foot, engineers ensure that immovable storage units remain stable and secure.

Calculating Line Load for Movable Systems

For movable systems, such as high-density mobile shelving, line load calculations are often more accurate. Here’s how it works:

- Measure the weight in front of the first rail and each subsequent section.

- Divide the total weight across the rail system, considering each rail’s load-bearing capacity.

- Multiply the resulting figure by the number of carriages, adding the weight of the rails to find the system’s total load.

This method allows structural engineers to determine whether the floor can support the system’s dynamic weight and movements.

Floor Loading Reinforcement Options

If a floor cannot support the calculated load, reinforcement options are available:

- Support Posts and Jacks: Installed beneath the floor to provide additional support.

- I-Beam or Box Beam Reinforcement: Positioned under the rails for added stability.

- Carbon Fiber Reinforcement: A modern solution that adds strength without significant structural changes.

Seismic Considerations

Seismic stability is essential, especially in regions near fault lines. Factors like ground composition, foundation type, and floor level impact the design of seismic anchoring systems.

Seismic Anchoring Options

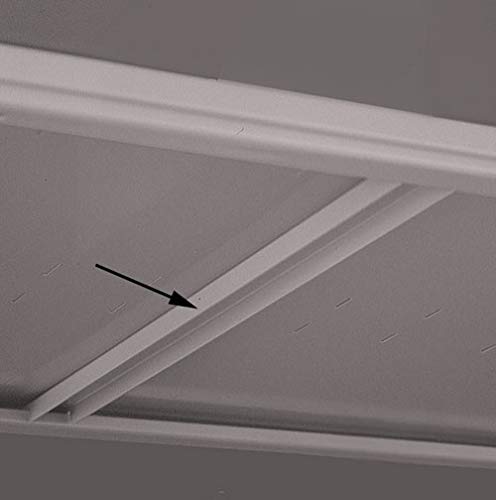

- Mobile Products: Rails should be securely anchored to the floor to prevent shifting during seismic activity. Pull tests assess rail deflection.

- Shelving Products: Anchoring systems may include floor base anchors, aisle ties, and wall anchors.

- Rotary Cabinets: Floor anchors provide stability, keeping cabinets in place during seismic events.

In Chapter 6, we cover the importance of proper floor loading calculations and the available reinforcement and seismic anchoring options. These considerations ensure that mobile storage systems are safe, stable, and compliant with structural standards, even in areas with seismic activity.

We Are MH USA

At MH USA, we specialize in providing innovative storage solutions that are tailored to your specific needs. As a trusted name in the material handling industry, we understand the importance of efficient storage planning and the role it plays in optimizing space and productivity. Our team is dedicated to helping architects, designers, and businesses create storage systems that are not only functional but also compliant with all federal regulations.

With years of experience in delivering high-quality storage products and services, we bring expertise and reliability to every project. Whether you’re taking the AIA Storage Planning Course or looking for customized storage solutions, MH USA is here to support you every step of the way.

Contact MH USA today for personalized assistance and discover how our tailored storage solutions can improve your business operations. Let us help you maximize efficiency and cost-effectiveness with a solution designed specifically for you.

-

3 Shelf Unit, 300B, 36"W, 72"L, 96"H, Archive with Particle Board Decking, Jaken, Jaken Boltless Shelving

Jaken Boltless Shelving 72″L x 36″W x 96″H Series 300B – 3 Shelf Archive Unit Particle Board Decking$342.18Original price was: $342.18.$191.62Current price is: $191.62. Add to cart -

Add-On Unit, Basket Shelving, Metro

$1,951.00Original price was: $1,951.00.$1,071.43Current price is: $1,071.43. Add to cart -

3 Shelf Unit, 30"W, 300B, 72"H, 96"L, Complete Unit with Particle Board Decking - Heavy Duty, Jaken, Jaken Boltless Shelving

$392.59Original price was: $392.59.$219.85Current price is: $219.85. Add to cart -

3 Shelf Unit, 300B, 48"W, 60"H, 60"L, Complete Unit with Particle Board Decking - Heavy Duty, Jaken, Jaken Boltless Shelving

$1,240.33Original price was: $1,240.33.$694.58Current price is: $694.58. Add to cart -

24"W, 84"H, 96"L, Complete Unit with Heavy Duty Wire Mesh, Jaken, Jaken Boltless Shelving, Series 200B

$379.31Original price was: $379.31.$212.41Current price is: $212.41. Add to cart -

48"W, 84"H, 96"L, Complete Unit with Wire Mesh, Jaken, Jaken Boltless Shelving, Series 200B

$598.56Original price was: $598.56.$335.19Current price is: $335.19. Add to cart -

30"W, 300B, 72"L, Extra Shelf, Jaken, Jaken Boltless Shelving, Particle Board Decking- Heavy Duty

$90.60Original price was: $90.60.$50.74Current price is: $50.74. Add to cart -

36"W, 96"H, 96"L, Complete Unit with Particle Board Decking - Heavy Duty, Jaken, Jaken Boltless Shelving, Series 200B

$391.29Original price was: $391.29.$219.12Current price is: $219.12. Add to cart