A parts drawer cabinet is the ultimate high-density storage system for the small to medium sized components that keep your operation running. For managers and buyers, this is how you transform a chaotic stockroom into a model of efficiency. Every screw, resistor, or washer gets its own dedicated, easy to find home, creating the foundation for a truly productive workspace.

Why a Parts Drawer Cabinet Is Your Organizational Cornerstone

Imagine your small parts inventory is a major highway during rush hour. Without organization, it becomes one massive traffic jam. Finding a single critical component turns into a frustrating hunt, causing delays that ripple through your entire operation. A parts drawer cabinet acts as your intelligent traffic control system, creating clear, designated lanes for every single item.

This systematic approach immediately solves common operational headaches. Instead of team members wasting precious time digging through messy bins, they can retrieve what they need in seconds. That speed translates directly into better productivity, faster order fulfillment, and lower operational costs.

The Financial Impact of Smart Storage

Investing in proper storage is a strategic business move. Disorganization is expensive; it leads to over ordering, misplaced stock, and crippling production delays. These are the kinds of problems that directly impact your bottom line and can even tarnish your reputation with customers. A quality parts drawer cabinet system creates a framework for precision and accountability.

The market backs this up. The global small parts storage market has surged to USD 2.06 billion, driven by the intense demands of lean manufacturing and e commerce. When you learn that over 60% of inventory errors are tied to disorganized small parts, it's easy to see how these cabinets can slash retrieval times by up to 40%. You can explore more data on the small parts storage market to see the full picture.

A well organized parts room is the foundation of a lean operation. It eliminates the waste of motion, time, and resources, allowing your team to focus on value adding tasks instead of searching for materials.

A simple comparison makes the benefits crystal clear. Implementing a professional parts drawer cabinet system is not just an upgrade; it is a fundamental shift in how your operation functions, moving from reactive chaos to proactive control.

Operational Impact of Organized vs Disorganized Storage

| Operational Metric | Without Parts Drawer Cabinets | With Parts Drawer Cabinets |

|---|---|---|

| Inventory Accuracy | Low; frequent stockouts or overstock | High; real time visibility and control |

| Retrieval Time | High; minutes or hours spent searching | Low; seconds to locate and pick |

| Space Utilization | Poor; wasted vertical and floor space | Excellent; high density storage in a small footprint |

| Operational Errors | Frequent; wrong parts picked, orders delayed | Minimal; precision picking reduces errors |

| Productivity | Low; valuable time lost to non value tasks | High; staff focused on core responsibilities |

The takeaway is simple: organized storage is a direct path to a more profitable and reliable operation.

Transforming Chaos into Operational Excellence

The advantages go far beyond just a cleaner room. Putting a robust parts storage solution in place delivers serious competitive edges that boost your overall efficiency and control.

- Boosted Inventory Accuracy: Know exactly what you have and where it is. This is key to preventing stockouts and stopping wasteful over purchasing.

- Maximized Floor Space: These high density drawers pack more items into a much smaller footprint than traditional shelving, giving you back valuable workspace.

- Faster Retrieval Times: When employees can find and pick parts in moments, you cut down on costly downtime and keep the entire workflow moving smoothly.

- Enhanced Security: Protect your valuable components from loss, damage, or theft with secure, lockable drawers.

Ready to eliminate bottlenecks for good? Request a Quote for a free, no obligation layout and see exactly how our solutions can transform your space.

Matching Cabinet Materials and Types to Your Workspace

Choosing the right parts drawer cabinet is like selecting the right tool for a job; you would not bring a scalpel to a construction site. Your specific environment, the parts you are storing, and your team's daily workflow should drive your choice. Get it right, and you have made an investment that pays off in efficiency; get it wrong, and it is just another piece of metal taking up space.

The first major decision is the cabinet's basic form. Each is built to solve a specific problem, whether it is saving floor space or bringing parts directly to a project.

Stationary, Mobile, and Wall Mounted Cabinets

You will generally find three main types of parts cabinets, each with its own sweet spot:

- Stationary Cabinets: These are the bedrock of any fixed workspace. Think of them as the permanent home for your inventory in stockrooms, labs, or on an assembly line. They are built for stability and high capacity, giving you a reliable, central hub for your most used components.

- Mobile Cabinets: Add casters to a cabinet, and you have a game changer for efficiency. These units bring the parts right to where the work is happening. They are perfect for large maintenance bays or sprawling assembly floors where walking back and forth to a central stockroom is a massive time waster.

- Wall Mounted Cabinets: When floor space is a luxury you do not have, the only way to go is up. Wall mounted units are brilliant for smaller workshops, garages, or labs. They keep critical components at arm's length without cluttering up your valuable floor real estate.

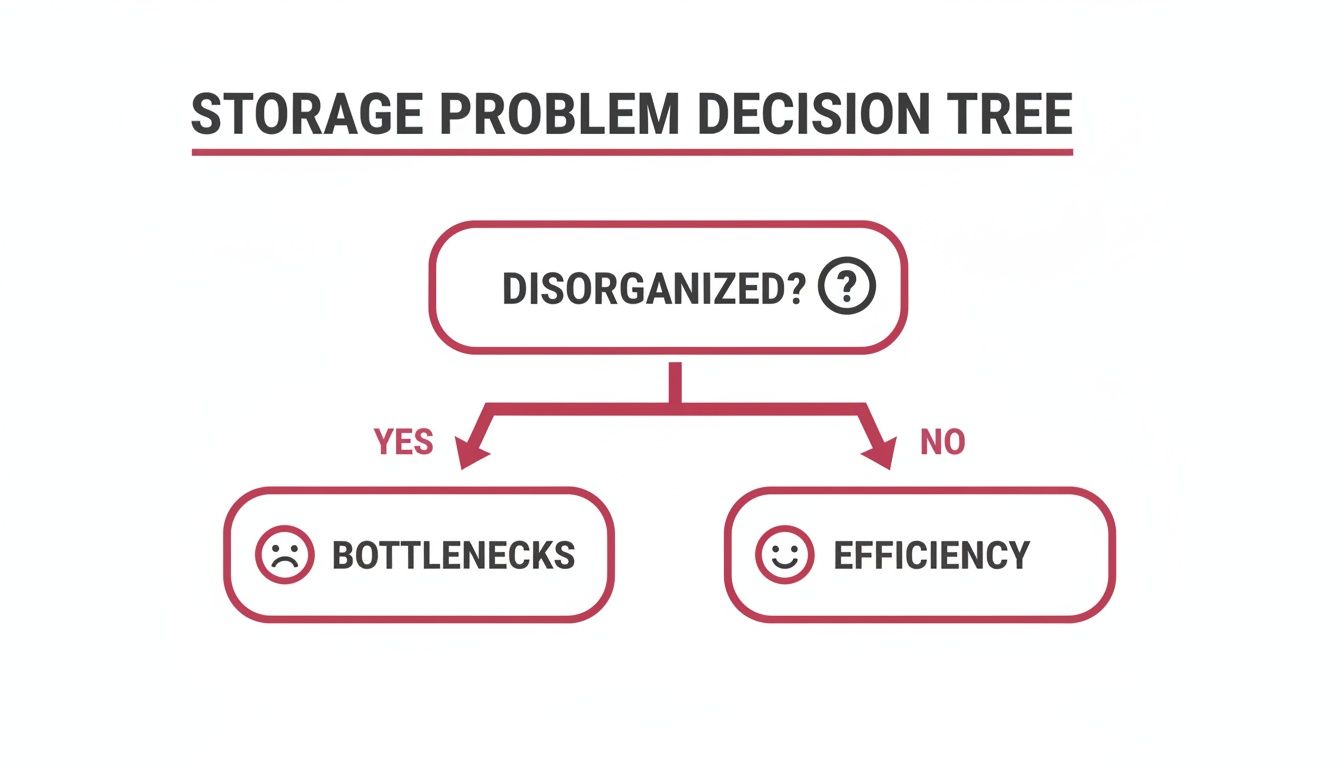

It all boils down to organization. A messy system creates bottlenecks, but the right setup clears the path for smooth, efficient work.

As you can see, tackling disorganization head on is the first step toward a more productive operation.

Steel vs. Plastic Construction

Just as critical as the cabinet type is what it is made of. The classic debate is steel versus plastic, and it usually comes down to a simple trade off: rugged durability versus upfront cost.

A parts drawer cabinet is an investment in durability. For most industrial applications, the superior strength and longevity of steel offer the best long term value by resisting dents, warping, and daily wear and tear.

For any serious industrial setting, heavy duty steel is the undisputed champion. Its rugged construction can handle incredible weight and shrug off the tough conditions you would find in a manufacturing plant, repair shop, or automotive garage. If you are dealing with moisture or chemicals, look for a powder coated finish. This is not just paint; it is a baked on protective layer that fights off rust and corrosion, adding years to the cabinet's life.

Plastic cabinets have their place in lighter duty applications or clean office environments where the demands are much lower. When you pair the right cabinet with other smart storage, you build a complete ecosystem. You can learn more about how to integrate a parts shelving system to create the ultimate setup.

Need help selecting the perfect cabinet for your facility? Our experts offer free layout designs with no obligation. Call (800) 326-4403 to get started.

Understanding Drawer Mechanics for Peak Performance

A parts drawer cabinet is only as good as its drawers. You can have the toughest frame in the world, but the drawer mechanics dictate day to day efficiency, durability, and whether your team loves or hates using it. Getting this part right is essential for a cabinet that stands up to constant use.

The heart of a drawer's performance is its slide mechanism. These slides deliver smooth, safe, and complete access to everything you have stored. A cheap or poorly designed slide will lead to frustrating jams, drawers that do not open all the way, and premature failure, disrupting workflow and forcing costly replacements.

Ball Bearing vs. Roller Slides

When it comes to slides, you are generally looking at two main options: ball bearing and roller slides. Each has its place, but for serious industrial use, there is a clear winner.

- Ball Bearing Slides: These are the gold standard. They use small, precision steel ball bearings that create an incredibly smooth, low friction glide. This design allows them to handle heavy loads effortlessly, making them perfect for storing dense items like bags of metal fasteners or heavy machine tools.

- Roller Slides: This is a more budget friendly choice, using simple plastic or nylon rollers that move along a track. They are fine for lighter duty applications, but they cannot offer the same effortless motion or high weight capacity as their ball bearing counterparts.

If your cabinets are going into a demanding environment where drawers will be opened and closed all day, investing in ball bearing slides is a no brainer. They ensure longevity and a much better user experience.

The evolution of these cabinets is directly tied to advancements in the drawer slides market, which is now valued at a staggering USD 6.86 billion. High quality ball bearing slides can slash friction by 90%, potentially extending the life of a cabinet by 5 to 7 years. These kinds of upgrades are a big reason why businesses see a 72% ROI boost from improved systems; it is a financial impact you can measure. You can discover more insights about the drawer slides market and its growth.

Why Full Extension and Dividers Are Critical

Beyond the slide type, there are two features that are absolutely non negotiable if you want to get the most out of your cabinet.

First, full extension slides are a must have for complete access. They allow the drawer to pull entirely clear of the cabinet frame, revealing every single item inside, even the items tucked away at the very back. This completely eliminates blind spots and ensures no component is ever difficult to reach.

Adjustable dividers are the key to unlocking true high density storage. They transform a simple drawer into a highly organized grid, preventing small parts from mixing and allowing you to customize each compartment to your exact inventory needs.

Finally, adjustable drawer dividers and bins give you the granular control needed for organizing small parts. These simple inserts let you partition a drawer into multiple smaller compartments, perfectly sized for everything from tiny electronic resistors to larger fittings. This level of customization is what turns a simple storage unit into a high performance organizational system that directly improves picking speed and inventory accuracy.

Ready to find a parts drawer cabinet with the right mechanics for your needs? Contact Us for a free consultation.

How Different Industries Use Parts Drawer Cabinets

A parts drawer cabinet is much more than a simple storage box. Think of it as a specialized tool that adapts to solve the unique challenges you face every day. Seeing how these cabinets perform in the real world is the best way to understand their true value.

From the frantic pace of a fulfillment center to the high stakes environment of a secure evidence room, their impact on efficiency and accuracy is huge. Each industry leans on specific features to overcome its own operational hurdles. For an e commerce warehouse, speed is everything. In an auto shop, it is all about precision. A laboratory prioritizes security and sample integrity above all else.

Automotive and Repair Shops

Walk into any busy automotive repair shop, and you will see technicians juggling a staggering number of small, mission critical parts. Misplacing a single bolt or washer can bring a complex repair to a grinding halt, resulting in wasted time and unhappy customers. High density drawer cabinets create one central, organized system for every last fastener, fuse, and connector.

By using modular drawers with adjustable dividers, shops can create custom layouts for specific vehicle models or common repair types. This systematic approach means a technician can find the exact part they need in seconds, not minutes. You can see how our automotive modular drawers are engineered specifically to meet these tough demands.

E Commerce and Fulfillment Centers

For any e commerce operation, the speed of order fulfillment is a make or break advantage. A parts drawer cabinet becomes essential for organizing the thousands of small SKUs that are a nightmare to manage on large pallet racks. By storing small, high volume items in partitioned drawers, picking accuracy and speed get a massive boost.

This level of organization is critical for keeping inventory counts accurate and slashing costly picking errors. The right system directly translates to happier customers and a healthier bottom line, ensuring orders are packed correctly and shipped out fast, every time.

Not sure how to configure your space for maximum efficiency? Our experts provide complimentary, no obligation layouts. Contact us to get started and optimize your storage!

Laboratories and Secure Environments

In places like laboratories, law enforcement evidence rooms, and other secure facilities, the stakes are much higher than just efficiency. Here, inventory control is a matter of security, compliance, and integrity. Lockable drawer cabinets provide a secure, auditable solution for storing sensitive samples, critical evidence, or high value electronic components.

The indoor cabinet market has grown into a USD 1.68 billion industry, driven largely by these critical needs. For law enforcement, these secure cabinets help manage millions of items every year, cutting loss rates from a shocking 8% down to under 1%. In e commerce, they can deliver 45% throughput gains, proving their value in both high security and high speed settings. You can explore additional market research on indoor cabinets to see the full scope of their impact.

Integrating Cabinets into Your Broader Storage Strategy

A parts drawer cabinet is an incredibly powerful tool on its own, but its true value shines when it is part of a larger, well thought out storage ecosystem. Instead of seeing it as just another piece of equipment, think of it as a key player that makes everything else you have work better. A smart integration strategy can transform a collection of individual storage units into a single, cohesive system that cuts out waste and boosts productivity across the board.

The real goal here is to create logical workflows where every piece of equipment works in harmony. This means doing things like strategically placing your high density cabinets right where the work happens, eliminating unnecessary trips back and forth for your team.

Creating High Efficiency Work Zones

A classic mistake is to treat all storage like a single, central warehouse. A much better approach is to create specialized work zones. When you pair a parts drawer cabinet directly with a workbench or a specific bay of industrial shelving, you create a self contained station for certain tasks.

For example, a maintenance area could have a mobile cabinet stocked with every necessary fastener and small component, sitting right beside the larger tools on the shelves. This concept, known as point of use storage, is a game changer. It drastically cuts down on travel time, which is one of the biggest hidden drains on any operation's budget. An employee who can simply reach for a part instead of walking across the facility is an employee who gets the job done faster.

The most efficient storage systems are designed around movement. By minimizing the distance between parts, tools, and the task at hand, you can reclaim hours of lost productivity every week.

Scaling and Labeling for Future Growth

One of the best things about a modular parts drawer cabinet is how easily it scales. As your inventory inevitably grows, you can add more units to expand your capacity without having to rip everything out and start over. This kind of modularity allows your storage to grow right alongside your business, ensuring you are never caught flat footed by expansion.

Of course, as you add more cabinets and parts, a clear and consistent identification system becomes absolutely critical. To find what you need in seconds and truly maximize efficiency, a bulletproof labeling system is non negotiable. As you integrate your cabinets, consider using effective labeling solutions like Traffolyte labels for their durability and clarity. For a deeper dive into setting up a system that works, check out our guide on labeling and bin location systems for efficient parts rooms.

Your Essential Parts Drawer Cabinet Buying Checklist

Making the right choice on a parts drawer cabinet comes down to asking the right questions before you make a purchase. We have pulled together all the key decision points into one simple, actionable checklist. Use it to pin down your exact needs, cut through the noise of the buying process, and pick the perfect cabinet with total confidence.

Going through these questions will not just arm you for a productive chat with our team; it will guarantee that whatever you choose directly solves your biggest operational headaches.

Pre Purchase Evaluation Checklist

Use this table to map out your core requirements before you even start looking at models. Having clear answers makes the selection process a breeze and helps our experts point you to the perfect unit for your space, fast.

| Consideration | Your Requirement | Notes |

|---|---|---|

| Environment | (e.g., Workshop, Cleanroom, Lab) | Is dust, moisture, or chemical resistance a factor? |

| Items Stored | (e.g., Nuts, bolts, resistors, samples) | What are the smallest and largest items you need to store? |

| Weight Capacity | (e.g., Light electronics, heavy fasteners) | Calculate the approximate weight per drawer. |

| Cabinet Type | (e.g., Stationary, Mobile, Wall Mounted) | Do you need parts at a fixed station or brought to the job? |

| Security Needs | (e.g., None, Keyed lock, Central lock) | Are you storing high value or sensitive items? |

| Drawer Configuration | (e.g., Dividers, bins, open) | How much granular organization do you need per drawer? |

Finalizing Your Decision

With your requirements clearly defined, you are in the perfect spot to select a system that will deliver immediate value. Now, think about how this new cabinet will actually fit into your day to day workflow. Will it be a standalone unit, or does it need to integrate with your current shelving and workbenches?

Do not forget to think about the future, too. It is always smart to consider a modular system. This allows you to scale up your storage as your operation grows, without having to rip everything out and start over. A little foresight now ensures your investment keeps paying off for years.

Ready to turn that checklist into a real solution? Our team is on standby to help you find the perfect parts drawer cabinet with competitive pricing and the fastest shipping in the business.

Request a Quote for a free, no obligation layout and design, or Call (800) 326-4403 to speak with a storage expert today.

Your Partner in Strategic Storage Solutions

Choosing the right parts drawer cabinet is not just another purchase; it is a strategic investment in the efficiency and accuracy of your entire operation. Getting this right comes down to choosing the best materials, understanding how the drawers function, and matching the cabinet’s features to what your industry actually demands day in and day out.

When you nail these critical elements, you create a system that actively cuts down on wasted time, slashes costly inventory mistakes, and gives your team a real productivity boost. The end result is a smoother, more profitable operation.

Ready for a More Efficient Workspace?

We are committed to providing high quality solutions at competitive prices, all backed by the fastest shipping and delivery in the business. Our mission is to ensure you get the best value and see a return on your investment as quickly as possible.

Whether you are ready to order today or you need expert guidance to map out a more complex facility layout, our team is here to help at every stage. We bring extensive hands on experience to the table to help you configure the perfect system.

A well planned storage system is not an expense; it is a powerful asset that drives operational excellence. Take the first step toward transforming your workspace with a solution built to last.

To get started, we invite you to use our complimentary design services. Let our experts create a free, no obligation layout and quote tailored specifically to your needs. It is the perfect way to see exactly how a professional parts drawer cabinet system can overhaul your space and workflow. Let's build a more organized, efficient, and productive workspace together.

Ready to upgrade your storage strategy? The experts at Material Handling USA are here to help you find the perfect solution.

Request a Quote for a free, no obligation layout and design, or Call (800) 326-4403 to speak with a storage expert now.