Think of your pallet rack system like a bridge. It’s engineered to carry a very specific amount of weight safely, but pushing it past that limit is asking for a catastrophic failure. The pallet racking weight capacity is the absolute maximum load your system can handle before its structural integrity is compromised. It’s not just one number, but a complex calculation that always comes down to the weakest component in the entire setup.

Understanding Your Pallet Racking Weight Capacity

Getting the weight capacity right is the first step toward a safer, more efficient warehouse. A simple miscalculation can lead to bent beams, damaged inventory, costly downtime, and—worst of all—serious injuries. A truly reliable storage system is built on a foundation of safety, and that foundation begins with knowing the limits of every single component.

This guide will break down the essential factors you need to consider, so you can make smart decisions when planning a new layout or upgrading your facility. We’ll start with the core structural parts that work together to give your system its true strength.

Key Components Defining Rack Weight Capacity

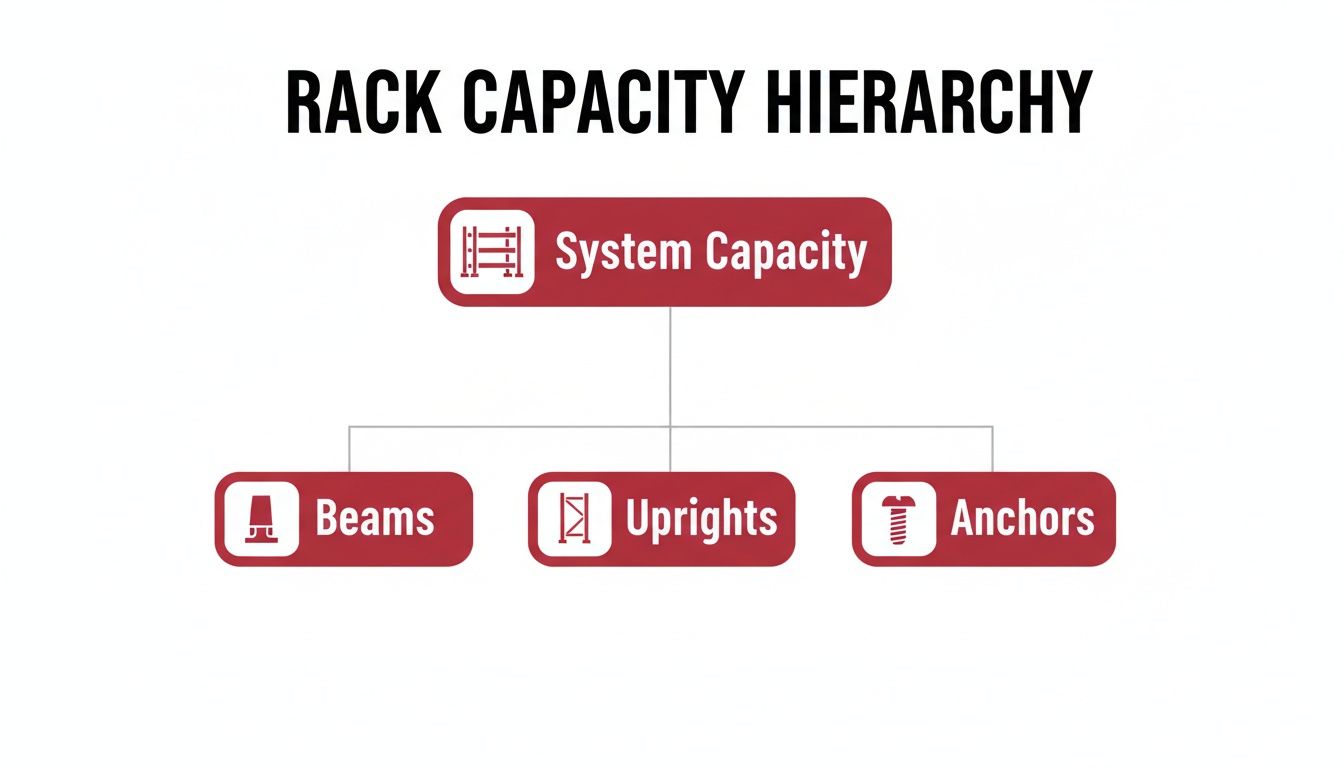

Every pallet rack is a system where individual parts share the load, but the total capacity is always dictated by the weakest link in the chain. Understanding what each component does is crucial for safe and effective warehouse planning. As warehouse project timelines continue to stretch due to high demand for materials and installers, getting these fundamentals right from the start ensures a much smoother and faster implementation.

This table provides a quick overview of the primary structural parts and the specific load capacities they are rated for, helping you grasp the core concepts at a glance.

| Component | Capacity Type | Primary Function |

|---|---|---|

| Beams | Per Shelf Level | These horizontal members directly support the weight of your pallets. Their capacity depends on length, height, and steel thickness. |

| Upright Frames | Per Bay Section | These vertical structures bear the total weight from all beam levels. Capacity is affected by height, depth, and column design. |

| Anchors & Footplates | System Stability | These components secure the rack to the floor, providing stability against tipping from impacts, uneven loads, or seismic activity. |

Ultimately, a safe system requires that the load on each component stays well within its rated limits. When you are ready to ensure your warehouse is both safe and efficient, our team can help. We provide free layouts and designs with no obligation to help you get started.

You can Request a Quote or call us at 800-326-4403 to speak with a design expert today.

How Beams and Uprights Determine Load Capacity

To really get a handle on your system’s limits, you have to look at its core building blocks: the beams and the upright frames. Think of them as the skeleton of your storage system. Each part has a specific job and a specific strength, and the way they work together dictates the overall pallet racking weight capacity. Nailing this relationship is fundamental to building a warehouse that’s both safe and efficient.

The entire structure is a carefully balanced equation. A small tweak in one area, like the spacing between shelves, can drastically change the total weight your system can safely hold. Let's pull back the curtain on each component and see how it contributes to the final number.

The Role of Pallet Rack Beams

Beams are the horizontal steel bars your pallets actually sit on, making them the first line of defense in supporting your inventory. The beam capacity tells you the absolute maximum weight a single pair of beams—one shelf level—can hold.

This capacity isn't just a random number; it's engineered based on three key factors:

- Beam Length: It's a simple rule of thumb: longer beams have a lower weight capacity. The wider the span, the more susceptible the beam is to bowing or deflecting under a heavy load.

- Beam Face Height: The height of the beam's front face is a direct clue to its strength. A beam with a 6-inch face is worlds stronger than one with a 4-inch face of the same length.

- Steel Gauge: The thickness of the steel itself is also critical. Heavier gauge steel means more structural integrity and, you guessed it, a higher load rating.

It’s absolutely crucial that the total weight of the pallets on a single level never exceeds the rated capacity of that beam pair. You can explore a huge range of sizes and capacities in our guide to pallet rack beams.

Understanding Upright Frame Capacity

While beams support individual shelf levels, the upright frames are the vertical columns that bear the cumulative weight of the entire system. The upright frame capacity is the total load a single frame can handle from all the beam levels connected to it.

But this capacity is more complex than just a single number. It's heavily influenced by the vertical distance between beam levels, what engineers call the "unsupported span."

The larger the vertical gap between your beams, the lower the weight capacity of the uprights. A larger unsupported span makes the vertical columns more susceptible to buckling under pressure, effectively de-rating their strength.

For example, an upright frame might be rated to hold 24,000 lbs with 48 inches of vertical space between beam levels. But if you increase that spacing to 60 inches to fit taller pallets, the very same frame’s capacity could plummet to 19,000 lbs. This detail is a classic oversight during warehouse reconfigurations, and it creates a serious hidden safety risk.

This infographic breaks down how the individual capacities for beams, uprights, and even the floor anchors all contribute to the system's overall strength.

As you can see, a stable system depends on every single part doing its job, from the bolts in the floor all the way up to the top beam.

Bringing It All Together With Bay Capacity

Finally, these individual ratings all come together to give you the bay capacity. A bay is simply one section of pallet racking between two upright frames. Its total capacity is the maximum weight for that entire section, but it’s always limited by the component with the lowest rating.

This is the "weakest link" rule in action. Let's say you have beams rated for 5,000 lbs per level and an upright frame rated for 25,000 lbs. If you install six beam levels, your theoretical beam load would be 30,000 lbs (6 levels x 5,000 lbs). That's 5,000 lbs over the upright's capacity.

In this scenario, your actual bay capacity is capped at the 25,000 lbs the uprights can safely handle, not the 30,000 lbs the beams could theoretically hold. Getting these calculations right is non-negotiable for a safe warehouse design.

How to Calculate Your Pallet Load Requirements

Let's move from theory to the real world. This is where a safe, efficient warehouse design really starts to take shape. Figuring out your specific load requirements isn't just a math exercise; it’s a critical step that directly impacts the safety of your team and the lifespan of your racking.

Getting these numbers right from the beginning prevents costly mistakes down the road and ensures your pallet rack system is a perfect match for your inventory.

The whole process kicks off with one simple but vital question: what is the absolute heaviest pallet you will ever need to store? That number is the bedrock for every other calculation you'll make, so precision is everything. Let's walk through it, step by step.

Step 1: Determine Your Maximum Pallet Load

First things first, you need to pinpoint your single heaviest pallet load. We can't stress this enough: do not use an average weight. You must always design for the heaviest possible load to build in a reliable safety margin.

This calculation has two simple parts:

- Product Weight: The total weight of all the goods sitting on the pallet.

- Pallet Weight: The weight of the pallet itself. A standard wood pallet can weigh anywhere from 30 to 70 pounds, and you absolutely have to include it.

Maximum Pallet Load = Heaviest Product Weight + Pallet Weight

For example, if your heaviest product load comes in at 1,950 pounds and you're using a 50-pound pallet, your maximum pallet load is 2,000 pounds. This is the number you'll use for every calculation that follows.

Step 2: Calculate Required Beam Capacity

Once you have your max pallet load, the next step is figuring out the required capacity for your horizontal beams. This part is pretty straightforward and just depends on how many pallets you plan to store on each shelf.

Here's the formula:

Required Beam Capacity = (Maximum Pallet Load) x (Number of Pallets per Shelf)

Let's plug in our example. If your max pallet load is 2,000 pounds and you plan on storing two pallets side-by-side on each beam level, the math looks like this:

(2,000 lbs Max Pallet Load) x (2 Pallets per Shelf) = 4,000 lbs Required Beam Capacity

This means you need to select a pair of beams rated to hold at least 4,000 pounds. We always recommend choosing a capacity slightly higher than what you calculated. It's a cheap and easy way to add an extra buffer for safety.

Uniformly Distributed Load: The Golden Rule

It is absolutely vital that you design your system for a Uniformly Distributed Load (UDL). A UDL is exactly what it sounds like—a load that is spread evenly across the entire length of the beams. Every single rack manufacturer uses the UDL standard to rate their beam capacities.

A common and incredibly dangerous mistake is creating a point load. This happens when the weight gets concentrated in a small area, like placing one heavy pallet right in the middle of a beam rated for two pallets. A point load can cause a beam to bend or fail, even if the pallet’s weight is well below the beam's official UDL capacity.

The market's expected growth to USD 12.88 billion by 2025 shows just how critical standardized racking has become in modern logistics. Racks in the up-to-5-ton capacity range, which hold a massive 54.99% market share, are perfect for the mixed cases and boxes we see everywhere today. Here in North America, which accounts for 37.10% of the market, following standards like ANSI MH16.1 isn't optional. In fact, uniform load testing can slash system failures by up to 35%. You can learn more about how these trends shape warehouse safety by exploring the latest pallet racking market research.

Don't let simple miscalculations compromise your pallet racking weight capacity and the safety of your facility. With warehouse equipment in high demand, planning ahead is the only way to lock in your project timelines.

Let our experts help you get it right the first time. We offer a free, no-obligation layout and design service to ensure your system is perfectly optimized for your specific inventory and operational needs. Request a Quote today or give us a call at 800-326-4403 to make sure your project starts on a solid, safe foundation.

Hidden Factors That Impact Real World Capacity

The capacity stamped on your pallet rack beams is a crucial number, but it's really just the beginning of the story. Think of it as the sticker price—the real cost comes from several real-world variables that can dramatically lower your system's actual, safe load limit. Overlooking these hidden factors is one of the most common and dangerous mistakes we see warehouse managers make.

These details often fly under the radar until it’s too late, leading to failed inspections, surprise costs, and, worst of all, serious safety hazards. To build a rack system you can truly rely on, you have to look beyond the manufacturer's label and account for the unique conditions inside your own four walls.

Vertical Beam Spacing: The Unsupported Span

If there's one factor that quietly wrecks rack capacity, it's the vertical beam spacing. Engineers call it the "unsupported span," which is simply the vertical distance from one shelf level to the next. The bigger that gap, the more vulnerable your upright columns are to buckling under pressure.

It's just like trying to snap a twig versus a long branch. The longer the piece of wood, the easier it is to break in the middle. Your uprights work the same way; the more unsupported space between beams, the less weight they can safely hold.

We see this all the time: a team reconfigures their racks to fit taller pallets, but they don't check the original load charts. Simply increasing your beam spacing from 48 inches to 72 inches can slash an upright's capacity by 25% or more, turning a perfectly safe system into a major liability overnight.

Seismic Zone and Floor Integrity

Where your facility is located—and what it’s built on—plays a non-negotiable role in your true rack capacity. Every warehouse sits in a specific seismic zone, and that rating dictates strict design and anchoring rules to make sure the rack can handle ground movement.

Racks in high-risk seismic zones need beefier steel, bigger footplates, and much stronger anchoring hardware. Failing to account for this is a recipe for catastrophic failure during an earthquake. Our team can help you navigate the complexities of pallet rack seismic compliance and ensure your system is up to local code.

Just as critical is the concrete slab your racks are sitting on. The floor has to bear the immense weight of the rack, all your inventory, and the forklifts running up and down the aisles. Cracks, uneven spots, or a slab that's too thin can undermine the stability of the entire system.

The Impact of Component Condition

Even a perfectly engineered system is only as strong as its weakest link. The daily grind of warehouse operations, especially bumps and scrapes from forklifts, can seriously compromise your pallet racking weight capacity.

A small dent in an upright column or a slightly bowed beam might not look like much, but it can dramatically reduce its load-bearing strength. That’s why a regular inspection program is so important. You need to be actively looking for:

- Dented, twisted, or scraped upright columns

- Bent, deflected, or sagging beams

- Missing or damaged safety clips

- Sheared, loose, or missing anchor bolts

Ignoring what looks like "minor" damage is a gamble that can lead to progressive structural failure. Promptly repairing or replacing damaged parts isn't just a good idea—it's essential for keeping everyone safe.

The need for seriously robust storage isn't slowing down. In fact, the market for heavy-duty systems designed to hold over 10,000 lbs is booming, projected to grow from USD 795 million in 2025 to over USD 1.1 billion by 2035. These workhorse racks are indispensable in the automotive and chemical sectors and are a cornerstone for North American e-commerce giants, where they can boost storage density by up to 75% compared to just stacking pallets on the floor. You can dig into the numbers by reviewing the heavy-duty pallet rack market research.

Juggling all these variables is a lot to handle, but you don't have to figure it out on your own. Our free design process takes everything into account—beam spacing, seismic codes, floor conditions, and more—to deliver a safe, compliant, and highly efficient system. Request a Quote or give our experts a call at 800-326-4403 for a no-obligation consultation.

Maintaining Rack Safety with Regular Inspections

A safe warehouse is a productive one. Keeping your pallet racking weight capacity intact isn't a one-and-done task—it’s a commitment that starts the moment installation finishes and requires constant vigilance. The single most effective tool you have is a program of regular, thorough inspections to catch potential hazards before they become catastrophic failures.

Think of it this way: proactive checks help you find and fix damaged components on your own schedule. The alternative is a sudden rack failure that dictates the schedule for you, bringing operations to a halt and putting your team, inventory, and bottom line at risk.

Training Your Team to Spot Damage

Your forklift operators and warehouse staff are your eyes and ears on the floor. They are perfectly positioned to be the first line of defense against rack failure. Get them trained to spot and immediately report any sign of impact or wear, no matter how small it seems. A minor dent from a forklift might look insignificant, but it can dangerously compromise a component's strength.

The Rack Manufacturers Institute (RMI) is crystal clear on this: any visible damage, like a dent or crease, means that component must be unloaded immediately and professionally evaluated. It’s not a suggestion; it’s a non-negotiable safety policy that underscores just how seriously you need to take proactive reporting.

Empower your team by teaching them exactly what to look for.

Key Damage Indicators Checklist

Here’s a practical checklist covering the most common—and most dangerous—types of rack damage that require immediate action:

- Deflected or Bent Beams: Look for any sagging or bowing in the horizontal beams. This is a classic sign of overloading.

- Dented Upright Columns: Check for dents, creases, or twists in the vertical frames. Pay special attention to the lower levels, where forklift impacts happen most often.

- Sheared or Loose Anchors: Every footplate must be securely anchored to the concrete floor. Even one loose anchor can compromise the stability of the entire bay.

- Missing Safety Clips: These small but critical clips stop beams from being accidentally knocked upward and dislodged. If they’re gone, the shelf level is a hazard waiting to happen.

- Corrosion or Rust: Rust isn’t just ugly; it actively weakens the steel, silently reducing its load-bearing capacity. This is a major concern in cold storage or humid environments.

Making this checklist part of your team's daily or weekly routine helps build a culture where safety is everyone's responsibility.

The Value of Professional Inspections

While your internal checks are crucial, nothing replaces a periodic professional inspection from a qualified engineer. An expert brings a trained eye that can spot subtle structural problems an untrained person might miss. They can also confirm your system still complies with current safety standards and local building codes, which change over time.

Investing in a robust, well-maintained racking system is a strategic move that pays for itself in safety and uptime. In 2024, the global market for racks in the 5 to 15 ton capacity range hit a 31% market share. North America, representing 37.10% of that market, depends on these systems. Industry data shows that when these racks are paired with routine inspections, the risk of collapse can plummet by 40%. You can dig deeper into the numbers with the latest pallet racking market research.

Don’t wait for an accident to expose a weak point. If you see damage or feel uncertain about your rack’s condition, Contact Us or call 800-326-4403 for an expert consultation.

Get Expert Help for Your Warehouse Racking System

Designing a safe and efficient pallet rack system is a lot more than just ordering parts from a catalog. Getting it right demands a deep understanding of component capacities, precise load calculations, and a sharp eye for real-world factors like seismic activity and the integrity of your concrete floor.

Bringing in an expert takes the guesswork out of the equation. It eliminates serious risks and ensures your pallet racking weight capacity is calculated correctly and maintained for the long haul.

At Material Handling USA, we provide free, no-obligation layouts and designs built around your specific operational needs. Our team is here to walk you through all the complexities of your project.

Your Path to a Compliant and Optimized System

We get it—every warehouse has its own unique set of challenges. Our entire process is built to deliver a solution that’s not just safe but also incredibly productive, making sure no detail gets overlooked.

- Expert Layouts and Designs: We create custom plans that squeeze every bit of storage density out of your space while keeping safety and workflow front and center.

- Code Compliance: Our specialists are pros at navigating the maze of local building codes and permitting requirements, guaranteeing your system is fully compliant from day one.

- Quality and Speed: We offer competitive pricing on top-quality materials and have the fastest shipping in the industry, which means your project gets up and running sooner.

Investing in a professionally engineered system is, without a doubt, the smartest move you can make. It maximizes your space, protects your team, and delivers a strong return on your investment. With warehouse equipment in high demand, planning your project early is the best way to lock in faster installation timelines and sidestep potential delays.

Choosing to work with a professional isn't just about buying racks; it's about investing in a safe, compliant, and highly efficient operational backbone for your business. It is the most direct path to a successful and timely project completion.

To see exactly how we work with you, you can learn more about our pallet rack design services.

Don’t leave safety and efficiency to chance. Let our team bring the expertise you need to build a storage solution you can count on. Request a Quote online or give us a call at 800-326-4403 to start your free design consultation today.

Got Questions About Pallet Rack Capacity? We’ve Got Answers.

Even when you have the basics down, real-world situations pop up. Here are some of the most common questions our team gets about pallet racking weight capacity, along with practical answers to keep your operation safe and running smoothly.

What Should I Do If My Racks Are Missing Capacity Labels?

First things first: stop loading them. Immediately. Using a rack without a clearly posted capacity plaque isn't just a bad idea—it's a major safety violation that puts your people, products, and equipment in jeopardy.

This is a situation that requires a professional. A qualified engineer needs to perform an on-site assessment. They’ll analyze everything from the steel gauge and component design to the system's current configuration. From there, they can calculate the correct, safe load limits and issue new, compliant capacity plaques for you to install. This is the only way to get back in business safely.

If you're staring at unlabeled racks right now, give our team a call at 800-326-4403. We can help you get an evaluation scheduled.

How Does Beam Spacing Affect Upright Weight Capacity?

This is one of the most overlooked—and most critical—factors in rack safety. The distance between your beam levels, sometimes called the "unsupported span," directly impacts how much weight your upright frames can handle.

Think of it this way: the taller the unsupported section of an upright column, the more susceptible it is to buckling under pressure. A larger gap between beams means the upright has less overall strength. It’s a classic engineering trade-off.

That's why you must always consult the manufacturer's capacity charts. They provide specific upright capacities based on different beam spacings. If you decide to move your beams farther apart to fit taller products, you could unknowingly overload the frames, even if the pallet weights haven’t changed.

Can I Store One Heavy Pallet on a Beam Rated for Two Lighter Ones?

This is a common question, and the answer is almost always no. Here’s why: beam capacity ratings are calculated based on a Uniformly Distributed Load (UDL). This assumes the weight is spread out evenly across the entire length of the beams.

When you place a single, heavy pallet right in the middle, you create what’s known as a "point load." This concentrates all that force onto a very small area, which can cause the beam to sag, bend, or even fail catastrophically—even if the pallet’s weight is technically under the beam’s total capacity rating.

If you absolutely must store concentrated loads, you need to bring in an engineer. They can determine if your current beams are up to the task or if you need to upgrade to a heavier-duty beam designed for that specific application.

Are All Pallet Racking Systems Required To Be Anchored?

Yes. Without exception. Both the Rack Manufacturers Institute (RMI) and OSHA are crystal clear on this: every single pallet rack column must be securely anchored to the concrete floor with the correct footplates and anchor bolts.

Anchoring is what gives the entire rack system its stability. It’s your primary defense against the system tipping over from a forklift bump, an unbalanced load, or—depending on where you are—a seismic event. The specific anchor type, size, and number you’ll need depends on factors like your rack height, the total weight it will hold, and your local building and seismic codes.

At Material Handling USA, we know that a safe warehouse is a productive warehouse. Getting the details of pallet rack capacity right can feel overwhelming, but you don't have to figure it all out on your own. Let our experts provide a free, no-obligation design to make sure your system is safe, compliant, and built for your unique operation.

Request a Quote or call us today at 800-326-4403 to get started.