Why Choose Us?

Over 30 Years Of Experience

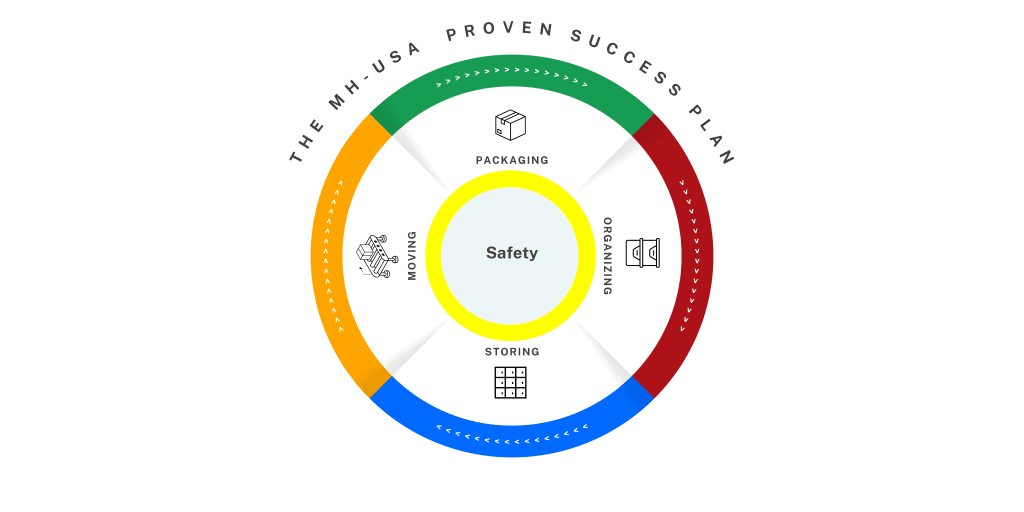

We design and install the right storage solutions for your specific needs

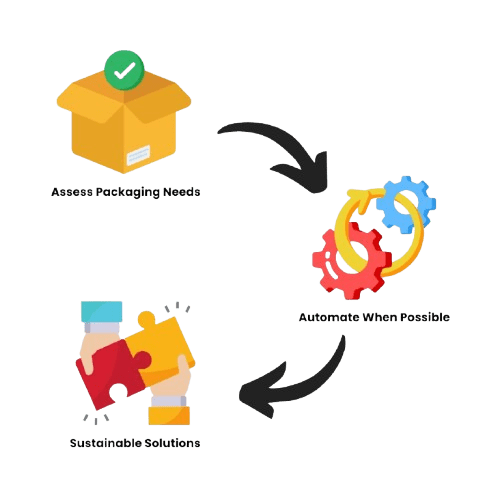

Custom

Options

We offer a range of customizable options to meet your unique needs

Customer Satisfaction

We are committed to excellent service and support, ensuring satisfaction with every purchase

Competitive Pricing

We offers competitive pricing, making it easy to find a solution that fits any budget