The Vidir Tire Carousel is a leading example of automated tire storage systems. Designed for high-density storage and retrieval, it offers several features that make it an ideal choice for businesses.

Material Handling Vidir Tire Carousel

See how automated tire storage systems maximize space, enhance safety, and streamline inventory management. Discover customizable solutions that fit your needs and hear success stories from businesses that have revolutionized their operations. Book a demo today to experience the benefits firsthand.

Automated tire storage systems are transforming how businesses manage their tire inventories. These advanced systems offer numerous benefits, including space savings, enhanced safety, and improved accessibility. By integrating motorized vertical carousels, like the Vidir Tire Carousel, businesses can optimize their tire storage, making every tire accessible at the touch of a button.

Schedule a Consultation: Let our experts guide you in selecting the ideal automated tire storage system for your space.

Automated tire storage systems provide numerous advantages over traditional storage methods. Let’s explore some key benefits:

One of the most significant advantages of automated tire storage is its ability to maximize space utilization. By storing tires vertically, businesses can save up to 70% of their floor space. Furthermore, this is particularly beneficial for facilities with limited space or high storage demands.

Safety is paramount in any workplace. Automated tire storage systems reduce the risk of injuries by delivering tires directly to the operator at an ergonomic height. This eliminates the need for manual lifting, bending, and pulling, which are common causes of workplace injuries.

Automated systems streamline the process of storing and retrieving tires, thereby significantly increasing efficiency and productivity. Additionally, with the touch of a button, tires are delivered quickly and accurately, thus reducing the time spent on manual handling.

Automated tire storage systems are highly customizable and scalable. They can accommodate various tire sizes, from small car tires to large truck tires, with or without rims. Businesses can choose from semi or fully automated systems, depending on their specific needs.

The Vidir Tire Carousel is a leading example of automated tire storage systems. Designed for high-density storage and retrieval, it offers several features that make it an ideal choice for businesses.

Automated tire storage systems come in various models to suit different needs. Below are some specifications for different tire sizes:

Automated tire storage systems are not just about saving space; moreover, they are also about enhancing efficiency. These systems are designed to integrate seamlessly into existing workflows, thereby providing a smooth transition from manual to automated operations.

The automated retrieval process ensures that the right tire is delivered quickly and accurately, thereby minimizing downtime and increasing operational efficiency. Additionally, this is especially crucial in high-demand environments where time is of the essence.

Automated systems come with advanced inventory management features, allowing businesses to track tire inventory in real-time. This helps in maintaining optimal stock levels and avoiding overstocking or stockouts.

By automating the storage and retrieval process, businesses can significantly reduce labor costs. Consequently, the need for manual handling is minimized, thereby freeing up staff to focus on other critical tasks.

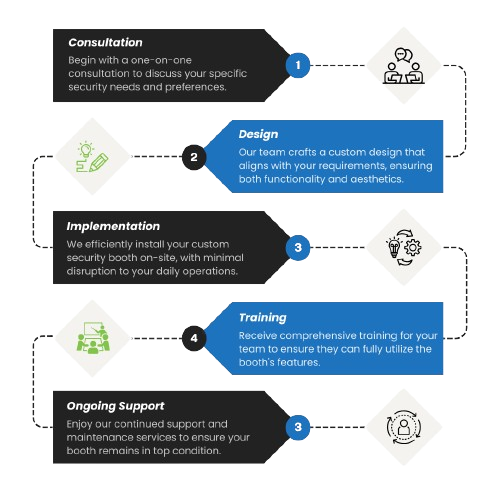

Implementing an automated tire storage system in your facility is a straightforward process. Here are the steps involved:

The first step is to assess your current storage needs and plan the layout of the automated system. This involves evaluating the types and quantities of tires you store and determining the best configuration for your space.

Once the assessment is complete, the system can then be customized to fit your specific requirements. This includes selecting the right model, configuring the storage parameters, and choosing additional features like security gates. Moreover, the installation process is quick and efficient, thereby minimizing disruption to your operations.

Training your staff on how to use the new system is crucial for maximizing its benefits. Additionally, most providers offer comprehensive training programs to ensure a smooth transition. Furthermore, regular maintenance is essential to keep the system running smoothly and efficiently.

Automotive dealerships often deal with a high volume of tire storage and retrieval. Automated systems help them manage inventory efficiently, provide quick access to tires, and improve customer service.

Tire retailers, moreover, benefit greatly from the space-saving and organizational features of automated storage systems. By utilizing these systems, they can store a wide variety of tire sizes and types, thus ensuring they always have the right tire in stock when customers need it.

Fleet management companies use automated tire storage systems to maintain their tire inventory for large fleets. This ensures that their vehicles are always equipped with the right tires, reducing downtime and improving operational efficiency.

Manufacturing plants that produce tires or use them in their production processes can benefit from the efficiency and organization provided by automated storage systems. This helps in streamlining their operations and reducing production delays.

With Automated Tire Storage, your facility’s potential is limitless. Enhance your space with storage solutions that combine durability, flexibility, and efficiency. Make the smart choice for your facility today with automated tire storage systems!

Experience the streamlined process of Material Handling USA’s automated tire storage solutions, guiding you from consultation to implementation with personalized solutions and ongoing support.

Over 30 Years Of Experience

We design and install the right storage solutions for your specific needs

Custom

Options

We offer a range of customizable options to meet your unique needs

Customer Satisfaction

We are committed to excellent service and support, ensuring satisfaction with every purchase

Competitive Pricing

We offers competitive pricing, making it easy to find a solution that fits any budget

Tate W. Curtis

Space Coordinator, United States Department of Agriculture

“ They always available for meetings and questions, firsts, in figuring out what system would work best for our needs then by assessinh how much shelving space would be required for our existing as well as future needs, and , finally, by insuring the timely delivery and quality installation of the product. ”

Sharon L. Hancey

First District TCE of Administrative Office of the Courts

“ They were extremely attentive in assessing our needs in Logan. They provided several plans to show us our shelving options. ”

Julie Froff

Assistant Clerck of

Third District Court

“ We have been using the system now for about six moths and are happy to report that it has been a wonderful addition to our office. It is easy to operate and keeps our filing area neat and organized, and most importanly, providers us with unlemited space for growth at this time. We are completely satisfied with your product. ”

Lila Abersold

Visual Arts Coorndinator of Utah Arts Council

“ The track and system Material Handling USA recently installed is working very well Your isntallation people were able to adjust the tracks on the uneven floor in our storage space. ”

Nancy Herd

Human Resources Manager of Ray Quinney & Nebeker

“ Thank you a million times for the these killer Jazz tickets! I am just so excited to go and rub shoulders with every other "pretentious" person in Material Handling USA! How Awesome! ”

An automated tire storage system is a motorized storage solution designed to store and retrieve tires efficiently. It uses vertical carousels to maximize space and improve accessibility.

The system works by rotating a vertical carousel that stores tires in a compact and organized manner. With the touch of a button, the desired tire is delivered to the operator at an ergonomic height.

Benefits include space savings, enhanced safety, increased efficiency, and improved inventory management.

Yes, automated tire storage systems are customizable and can accommodate various tire sizes, with or without rims.

You can save up to 70% of your floor space by utilizing vertical storage.

Yes, the system is designed to enhance workplace safety by reducing manual handling and delivering tires at an ergonomic height.

Yes, automated tire storage systems are designed to integrate seamlessly with existing workflows, providing a smooth transition from manual to automated operations.

Regular maintenance is essential to keep the system running smoothly. Most providers offer maintenance services to ensure optimal performance.

Yes, automated tire storage systems come with advanced inventory management features, allowing real-time tracking of tire inventory.

Assess your storage needs, plan the layout, customize the system, install it, and ensure regular training and maintenance.