Think about the last time a team member needed to reach something high up in your facility. Were they climbing on racking? Or worse, balancing on a wooden pallet lifted by a forklift? It’s a sight that makes any safety-conscious manager cringe, and for good reason.

A forklift work platform—often called a man basket or safety cage—is the professional, engineered solution to this exact problem. It’s an attachment that securely connects to your forklift’s forks, transforming it into a safe and stable mobile lift for your team.

Understanding Forklift Work Platforms

When your crew needs to get hands-on with tasks at height—like changing a lightbulb, performing maintenance on overhead equipment, or doing a quick inventory check on high racking—a wobbly ladder often won't cut it. You need to provide a secure, stable environment to work from. That’s precisely what a forklift work platform provides.

It’s a practical and efficient alternative to setting up bulky scaffolding for quick, short-duration jobs. Essentially, it turns your trusted forklift into a safe, mobile elevating work platform, getting your people where they need to be without the hassle or risk.

The entire point of these platforms is to eliminate the severe dangers that come with makeshift lifting methods. A purpose-built man basket creates a fully enclosed workspace. It has guardrails to prevent falls and a solid surface underfoot, a world away from the terrifying thought of someone standing on a loose pallet.

The Critical Difference: Safety and Compliance

Let’s be direct: the gap between a certified work platform and a homemade alternative is enormous. Lifting a worker on an empty pallet is one of the most reckless things you can do in a warehouse, and it’s a direct line to catastrophic injuries and OSHA violations.

The data doesn’t lie. Powered industrial trucks are involved in thousands of serious injuries every year, and a shocking number of those are from people falling from elevated forks. This is exactly why regulations are crystal clear: lifting people on bare forks is strictly prohibited. You must use a properly designed and manufactured work platform.

Facilities that get this right and implement formal procedures for using forklift work platforms see a dramatic drop in incidents. It’s a straightforward move that protects your team, keeps you compliant, and helps you avoid massive penalties.

These platforms fit perfectly into a broader strategy for running a safe and efficient operation. When integrated with other essential lifting and material transport equipment, they help create a seamless system that boosts productivity while putting worker well-being first.

Need help figuring out how to integrate a work platform into your existing fleet? Our experts are on hand to provide a free layout and design consultation. Request a Quote or give us a call at 800-326-4403 to get started.

Exploring Different Types of Work Platforms

When it comes to forklift work platforms, one size definitely does not fit all. Choosing the right one is all about matching the tool to the job you need to do. You wouldn't use a hand truck to move a multi-ton load, and the same logic applies here—picking the right platform is the first step toward boosting safety and getting the job done right.

Think about the tasks your crew handles most often. Are they doing quick, routine checks or are they tied up in heavy-duty repairs that need serious tools? Answering that question will point you directly to the perfect platform for your facility.

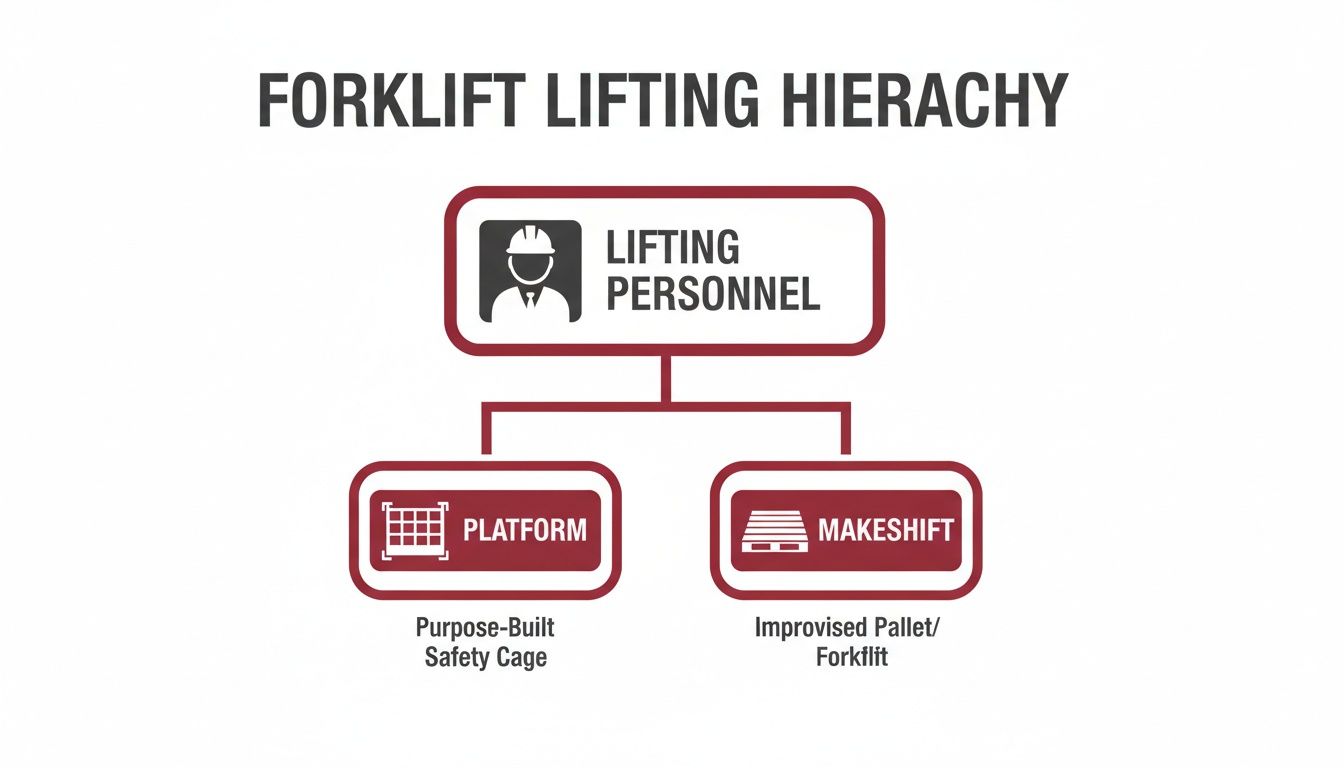

This infographic nails the difference between engineered safety and dangerous shortcuts.

It’s a stark reminder: only a purpose-built, properly engineered work platform is safe for lifting your team. Anything else is just asking for trouble.

Standard Duty Platforms

For most warehouses and facilities, the standard duty forklift work platform is the everyday workhorse. These are your go-to solution for routine, light-duty jobs that pop up all the time—things like changing out light bulbs, doing quick inventory counts on high shelves, or performing simple machinery inspections.

Typically built for a single worker, these platforms strike a great balance between being tough enough for the job and easy to maneuver. They come with all the mandatory safety gear, like sturdy guardrails, toeboards to keep tools from taking a tumble, and a non-slip floor. Because they're lighter, they're also a breeze to attach and detach, which keeps downtime to a minimum.

Heavy Duty Platforms

When the job gets serious, you need to bring in the big guns. A heavy duty forklift work platform is built to handle tougher tasks, bigger loads, and multiple workers. These are what you need for complex equipment repairs, major installation projects, or any job that requires bringing up heavy or bulky tools.

Made from reinforced steel, heavy duty platforms give you a larger workspace and can handle much higher loads, often exceeding 1,000 lbs. That extra capacity is a game-changer when you need two people working side-by-side or have to lift specialized equipment. Many models even come with handy features like built-in tool trays to make those demanding jobs a little easier.

Specialized Work Platforms

Sometimes, an off-the-shelf solution just won't cut it. That's where specialized platforms come in. If you're navigating the tight confines of a very narrow aisle warehouse, you might need a platform with custom dimensions. For order picking, a platform with integrated shelving can make the process faster and safer.

These custom-built platforms are designed to solve the unique operational headaches that standard models can't. While they might take a bit more planning to get just right, the payoff in workflow efficiency and safety for those niche tasks is huge.

To help you sort through the options, we've put together this table comparing the key features and common applications of each platform type. Use it to help you make an informed decision for your facility.

Forklift Work Platform Feature Comparison

| Platform Type | Common Applications | Typical Capacity (lbs) | Key Features |

|---|---|---|---|

| Standard Duty Platform | Light maintenance, inventory counts, inspections, changing light bulbs. | 500 – 750 | Guardrails, toeboard, non-slip floor, single-person capacity, fork pockets. |

| Heavy Duty Platform | Heavy tool use, machinery repair, two-person tasks, installation projects. | 1,000+ | Reinforced steel construction, larger floor space, optional tool trays, higher guardrails. |

| Specialized Platform | Order picking, specific equipment access, tasks requiring integrated storage. | Varies by design | Built in shelving, custom entry gates, specific dimensions for narrow aisles. |

Choosing the right platform from the start equips your team for success and prevents the frustrating delays that come from using the wrong tool for the job. Our experts are here to help you figure out exactly what you need. Request a Quote today or give us a call at 800-326-4403 for a no-obligation consultation.

Meeting OSHA Safety and Compliance Standards

For any manager running a facility, safety isn't just a talking point—it's the bedrock of the entire operation. When you're using forklift work platforms, knowing and following OSHA standards is completely non-negotiable. These rules aren't just red tape; they are life-saving protocols designed to prevent the kinds of accidents nobody wants to think about.

Wading through the official regulations can feel like a chore, but the core ideas are straightforward. They all point to one goal: making sure your team goes home safe at the end of every single shift.

The main regulation you need to know is OSHA standard 29 CFR 1910.178. This rule spells out the specific requirements for both the platform's design and how it's used. Instead of getting bogged down in legal text, think of it as a practical blueprint for safe operation. Following it protects your people from dangerous falls and your business from hefty violations, which can top $15,000 for a single serious incident. Embracing these standards helps you build a true safety culture, where doing things the right way is just how you work.

Core Design and Structural Requirements

OSHA gets very specific about how a work platform has to be built, and for good reason. These rules ensure the platform is a secure space before anyone even steps foot in it. This is exactly why makeshift solutions, like lifting someone on a wooden pallet, are strictly forbidden—they lack every single one of these essential safety features.

A compliant platform needs a guardrail system that's at least 42 inches high. This isn't just a top rail; it must also include a mid-rail to stop someone from slipping under it and toeboards along the floor to keep tools or parts from falling on people below. The floor itself has to have a non-slip surface to give workers solid footing.

On top of that, the platform must be engineered to lock securely onto both the forks and the mast of the forklift. This is critical for preventing the basket from tilting, shifting, or sliding off during a lift—a primary cause of horrific accidents. All our platforms are designed with beefy locking mechanisms and reinforced fork pockets that meet and exceed these strict rules.

Operational Protocols and Worker Safety

Beyond the physical hardware, OSHA lays out clear rules for how these platforms must be operated. These protocols create a system of checks and balances that involves both the person driving the forklift and the person being lifted.

A critical—and often missed—requirement is that you must have written approval from the forklift manufacturer before using any attachment to lift personnel. This confirms the forklift itself is actually rated for that kind of work.

The forklift operator has to stay at the controls the entire time workers are elevated. This isn't negotiable. It guarantees someone is always there to respond instantly and control the lift smoothly. At the same time, anyone inside the platform must wear proper fall protection. This usually means a full-body harness with a lanyard attached to a certified anchor point inside the basket, serving as a vital last line of defense.

Bringing these rules to life means looking at your facility's safety as a whole. For a deeper look at how these standards play into your overall layout, check out our guide on creating an OSHA compliant warehouse design to engineer safety into your floorplan.

Actionable Compliance Checklist

To make this simple, we've boiled the rules down into a checklist you can use every day. Use it before every lift to make sure you've covered all the bases. Using a checklist consistently helps turn safety protocols into second nature for your whole crew.

OSHA Compliance Checklist for Work Platforms

- Guardrails and Toeboards: Confirm the platform has 42-inch high guardrails, a mid-rail, and toeboards in good condition.

- Secure Attachment: Double-check that the platform is locked securely to the forks and mast, with all safety mechanisms engaged.

- Manufacturer Approval: Make sure that written authorization from the forklift manufacturer is on file and accessible.

- Fall Protection: Check that everyone in the platform is wearing a properly fitted harness and lanyard attached to the anchor point.

- Trained Operator: Verify the forklift operator is trained, certified, and will remain at the controls for the entire lift.

- Pre-Lift Inspection: Document that a pre-use inspection of both the forklift and the platform was completed and signed off on.

Meeting OSHA standards is an ongoing commitment to training, inspection, and reinforcement. By investing in high-quality, compliant forklift work platforms and making these practices part of your daily routine, you create a safer and more productive workplace.

How to Choose the Right Platform for Your Fleet

Picking the right forklift work platform is about more than just the price tag. The single most important factor is making sure it works seamlessly with the forklifts you already own. A mismatched platform isn't just a waste of money; it's a serious safety hazard waiting to happen.

Let's walk through what you need to look for to make sure your investment is a solid—and safe—one. You have to treat the platform and the forklift as a single, integrated system. This means digging into the specs of your equipment to confirm they line up perfectly. Skipping this step is a recipe for operational headaches and, worse, putting your team in danger.

Confirming Forklift and Platform Compatibility

First things first: get out a tape measure and check your forklift's forks. The platform’s fork pockets need to create a snug, secure fit. If the pockets are too big, the platform can shift or tilt mid-air, which is an incredibly dangerous situation. Too small, and it simply won't fit at all.

Next up is the forklift's rated capacity. You have to calculate the total weight—the platform itself, your workers, their tools, and any materials—and make sure it doesn't exceed what the forklift can safely lift. Always check the forklift's data plate, which spells out its capacity at different load centers and lift heights. Overloading is one of the fastest ways to cause a tip-over.

Finally, you need to confirm the platform is approved for your forklift’s specific class. A Class I electric sit-down rider is a different beast than a Class IV internal combustion truck. They have different designs and capabilities, so the platform you choose must be specifically approved for the type of forklift you're using.

Making an informed choice now prevents costly compatibility issues down the road. Our team offers free consultations to review your fleet's specifications, ensuring you select a platform that integrates perfectly with your current equipment.

The Rise of Electric Forklifts and Modern Fleets

The material handling world is changing fast. Electrification is reshaping how facilities get work done at height. Electric units are now the biggest segment of the forklift market, with their U.S. market share sitting around 60% and projected to grow by over 11% each year.

Why does this matter for you? Modern electric forklifts offer incredibly smooth and precise mast controls. This drastically cuts down on platform sway and gives operators more confidence when they're working 20 to 30 feet in the air. You can learn more about these forklift market trends and how they impact day-to-day operations.

A Practical Checklist for Platform Selection

To avoid the common pitfalls of purchasing, you need a system. Asking the right questions leads you to the right equipment, making sure your new forklift platform is a valuable asset from day one. A little planning now can help you align the purchase with upcoming maintenance cycles or facility projects, so you're not making a rushed decision that you'll regret later.

Use this checklist to nail down your selection:

- Fork Dimensions: Have you measured the width, thickness, and length of your forklift's forks?

- Fork Pocket Size: Do the platform's fork pockets match your fork dimensions for a secure fit?

- Weight Calculation: What is the total combined weight of the platform, personnel, and tools?

- Forklift Capacity: Does that total weight fall safely within your forklift's rated capacity at the required lift height?

- Manufacturer Approval: Do you have written approval from your forklift's manufacturer to use a personnel lifting attachment?

- Task Requirements: Does the platform's size and capacity (Standard vs. Heavy Duty) fit the jobs you need to get done?

Answering these questions ensures you're not just buying a piece of equipment, but investing in a solution that makes your facility safer and more productive.

Don't leave this critical decision to chance. Let our experts provide a free, no-obligation layout and design consultation to guarantee a perfect match for your fleet. Request a Quote or call our specialists at 800-326-4403 to ensure you get the right platform with the fastest shipping in the industry.

Putting Safety and Maintenance into Practice

Buying a top-notch forklift work platform is a great start, but getting the most out of it comes down to how you use it and take care of it. Consistent operational and maintenance routines are what turn a piece of equipment into a true safety asset. These habits protect your people, make the platform last longer, and give you a predictable, efficient way to get work done at height.

Without a solid plan for daily checks and safe operation, even the best gear can let you down. A tiny, unnoticed crack in a weld or a simple miscommunication between the driver and the worker can snowball into a major problem. By building these procedures right into your daily workflow, you make sure every lift is just as safe as the first one.

The Daily Pre-Use Inspection: Your Non-Negotiable Habit

Before a single worker steps onto that platform, a thorough pre-use inspection is mandatory. This isn't just a good idea—it's a fundamental safety requirement that needs to be documented every single day. This quick check is your number one defense against equipment failure.

The inspection needs to be systematic, covering every critical part of the forklift work platform. It’s like a head-to-toe checkup that ensures the equipment is fit for duty.

Daily Inspection Checklist

- Structural Integrity: Look closely at all welds for any sign of cracks, stress, or separation. Check the guardrails and toeboards for bending, damage, or loose connections.

- Floor Condition: Make sure the non-slip surface is intact and totally free of oil, grease, or any other debris that could cause a slip.

- Attachment Points: Examine the fork pockets and locking mechanisms. Confirm the safety chains or pins are there, working properly, and show no signs of damage.

- Gates and Latches: If your platform has a gate, test it. It needs to close securely with the latch engaging every time.

Safe Operating Procedures

Safe operation is a two-person job, a partnership between the forklift operator and the crew in the platform. You need clear, established rules to prevent accidents while lifting, moving, and lowering.

Communication is everything. Before the lift even starts, the operator and the worker must agree on hand signals and procedures. The operator has to stay at the forklift controls the entire time the platform is in the air, moving at a slow and steady pace. Any sudden starts or stops can be incredibly jarring and dangerous for the person up in the basket. For more great ideas, explore our resources to improve warehouse safety and productivity.

A cardinal rule of safe operation: never travel with the platform raised more than a few inches off the ground. The final lift to working height should only happen once the forklift is perfectly positioned at the work site.

Long-Term Maintenance and Care

Beyond the daily checks, a proactive maintenance schedule is crucial for keeping your forklift work platform in service for years to come. Regular, documented inspections help you spot wear and tear long before it becomes a safety hazard or requires a costly replacement.

The global forklift market is booming—projected to hit USD 152.7 billion by 2033—which means more and more of these platforms are being used in high-bay warehouses. As facilities build taller racking, the need for reliable tools for at-height maintenance grows, making platform upkeep a strategic priority. This trend highlights how owning forklift work platforms can slash reliance on rental equipment and cut repair times from days down to hours.

To keep your fleet in peak condition, it helps to have a solid plan. Looking at a comprehensive heavy equipment maintenance checklist can offer broader insights. At the end of the day, a well-maintained platform is a reliable one, always ready to go when you need it. Keeping your equipment in top shape helps you steer clear of project delays caused by unexpected downtime.

Making these practices part of your culture builds safety and responsibility from the ground up. If you need help finding a durable platform built for the long haul, our team is here to help. Request a Quote or call us at 800-326-4403.

Your Partner for a Safer and More Efficient Facility

We've covered a lot of ground in this guide, walking through everything you need to know about selecting, using, and maintaining forklift work platforms. If there's one thing to take away, it's this: getting safety, compliance, and the right equipment right isn't just a box to check—it's the foundation of a successful operation. Partnering with us means you’re getting more than just a piece of steel; you’re gaining a strategic advantage for your entire facility.

We're committed to giving you real value, from competitive pricing to what our customers consistently tell us is the fastest shipping in the business. But our job doesn’t end when the truck leaves. Our team of experts is always on standby to provide free layouts and design help, making sure the solution you get is the one that actually fits your needs.

Planning for Success

Thinking ahead is what separates the pros from the amateurs. A forklift platform isn’t just a standalone purchase; it's a piece of the much larger puzzle of warehouse logistics. Smart facility managers see how it all connects, planning their equipment buys now so they’re ready for the next big maintenance cycle or facility upgrade.

Securing the right equipment ahead of time empowers your team to execute projects without hitting frustrating delays. This is the kind of foresight that keeps an operation running smoothly, instead of constantly reacting to equipment shortages or compatibility headaches that could have been avoided.

When you prepare in advance, you get a handle on project timelines and sidestep the chaos that comes with last-minute scrambles for gear.

Your Next Step

We’re here to help you nail down the perfect forklift work platform—one that comes with guaranteed quality, expert backup, and the peace of mind that your team is ready for anything. Let our specialists guide you toward a confident investment that will boost both safety and productivity for years to come.

Take the next step toward a safer, more efficient facility. Request a Quote online for a free, no-obligation consultation, or give our team a call directly at 800-326-4403 to talk through your needs today.

Answering Your Top Questions

When it comes to forklift work platforms, a few questions pop up time and time again. Let's clear the air and give you the straightforward answers you need to make the right call for your facility.

Can I Use Just Any Forklift with a Work Platform?

That’s a hard no. You can't just slap a work platform onto any forklift in your fleet. It's crucial that the platform is specifically designed to be compatible with your forklift's class, capacity, and fork size.

Think of it this way: the total weight of the platform, the worker, and their tools can't even come close to exceeding the forklift's rated capacity for that lift height. Plus, OSHA is very clear on this: you need written approval from the forklift manufacturer to use any attachment for lifting people. If you're unsure, it's best to consult an expert. Give us a call at 800-326-4403 for a quick, free consultation to confirm compatibility.

Is a Safety Harness Really Necessary in the Basket?

Yes, absolutely. OSHA mandates that anyone inside a forklift work platform must be properly tied off with fall protection. This means a full-body harness connected by a lanyard to a designated anchor point inside the platform.

While the guardrails are the first line of defense, think of the harness as a critical backup. It's the safety net that protects a worker from a sudden jolt, an unexpected machine movement, or a catastrophic failure. There's no room for compromise here.

How Often Do I Need to Inspect My Forklift Man Basket?

Every single time, before every single use. A daily pre-shift inspection is non-negotiable. Your operator should be checking for any signs of trouble—cracks in the welds, bent railings, a compromised floor, or any issues with the locking pins that secure it to the forks.

Beyond the daily check, a more in-depth, documented inspection is also required. This should be done periodically, following the manufacturer’s guidelines and your own safety protocols. Most facilities schedule these thorough inspections semi-annually or annually.

What’s the Real Difference Between a Work Platform and a Pallet?

The difference is night and day—one is a life-saving tool, and the other is a life-threatening risk. A forklift work platform is a purpose-built piece of safety equipment, engineered from the ground up to lift people. It has 42-inch guardrails, mid-rails, toeboards, a non-slip floor, and a secure locking system because it's designed to protect human life.

A pallet, on the other hand, is designed for one thing: lifting materials. OSHA explicitly prohibits using a pallet to lift a worker. It’s one of the most dangerous things you can do in a warehouse and a direct route to serious injuries and massive fines.

At Material Handling USA, our goal is to equip you with high-quality gear that keeps your team safe and your operations compliant. Our experts are on standby to help you select the perfect forklift work platform for your fleet, and we back it all up with the fastest shipping in the industry.