Staring at an overflowing supply closet right next to a shelf that's completely empty of a critical item is a frustration that plays out in hospitals every single day. Hospital inventory management systems are the answer to this chronic chaos. Think of them as the operational brain connecting your hospital's entire supply chain directly to the point of patient care, making sure clinicians have exactly what they need, right when they need it.

The Critical Role of Hospital Inventory Management

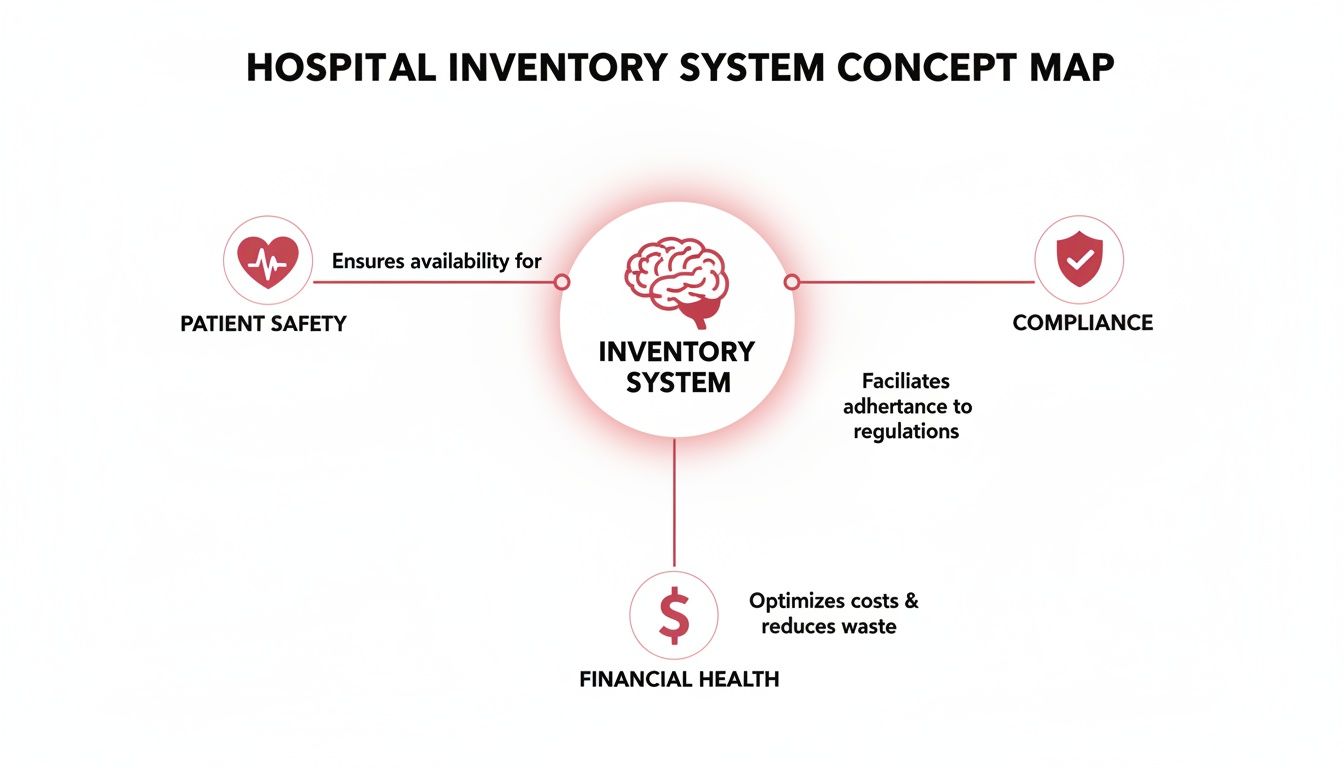

Effective inventory control isn't just an administrative chore. It's a core function that has a direct, tangible impact on patient safety, regulatory compliance, and your hospital's bottom line.

When inventory is managed poorly, the consequences create ripples that spread through the entire facility. A single missing catheter can delay a critical procedure. An overstocked shelf of medications nearing their expiration date represents thousands of dollars in pure waste. This is the exact problem a modern hospital inventory management system is built to solve.

Moving Beyond Manual Checklists

For too many years, hospitals got by with manual counts and paper checklists. This old-school approach is not just wildly inefficient; it's a breeding ground for human error, which leads to some serious, recurring headaches:

- Stockouts: Finding yourself out of essential supplies can compromise patient care and force you into costly, last minute emergency orders.

- Overstocking: Every extra box on the shelf is capital that's tied up, sitting there at risk of expiring or becoming obsolete.

- Wasted Staff Time: Clinicians are forced to spend precious time hunting for supplies instead of focusing on what they do best: caring for patients.

- Compliance Risks: If you can't accurately track lot numbers or expiration dates, you're opening the door to major regulatory penalties.

Think of an inventory system as the central nervous system for your hospital's supply chain. It gets signals from every department, processes that information in real time, and sends resources exactly where they’re needed to keep the whole operation healthy.

The Strategic Imperative for Modernization

Today, these systems are far more than digital checklists. They are intelligent platforms that give you real time visibility and control over your entire inventory. They automate the reordering process, track assets from the moment they arrive to the second they're used in the operating room, and provide the kind of data analytics that helps you accurately forecast future needs. When you master your inventory, you gain an incredibly powerful tool to secure your facility's financial health.

Putting a robust system in place is no longer just a good idea. It's a foundational investment in operational excellence and quality of care. The right system, supported by smart physical storage, transforms your supply chain from a reactive cost center into a proactive, strategic asset.

Ready to explore a solution with competitive pricing and the fastest delivery in the industry? Contact Us for a free quote and no obligation layout design.

Core Components of a Modern Inventory System

To get a grip on what makes a hospital inventory management system effective, you have to understand its fundamental building blocks. A modern system is really a combination of two things: specialized hardware that captures data on the ground and intelligent software that makes sense of it all. Working together, they create a responsive network that tracks every single supply, from the moment it hits the loading dock to the point it's used for patient care.

Think of the hardware as the system's eyes and ears. These are the physical tools that interact directly with your inventory.

- Barcode Scanners: These are the dependable workhorses of inventory management. They provide a straightforward, reliable way to track items as they're checked in, moved between departments, or used.

- RFID Readers and Tags: Imagine a hands free toll tag for every surgical kit and gauze pack. Radio Frequency Identification (RFID) technology lets your team scan items in bulk without needing a direct line of sight, which dramatically speeds up tasks like cycle counts and finding equipment.

- Smart Cabinets and Vending Machines: These secure storage units automatically record who takes an item, when they take it, and for which patient. This provides pinpoint accountability for high value supplies and pharmaceuticals.

This diagram shows how a well integrated inventory system becomes the central hub for improving patient safety, ensuring compliance, and strengthening your facility's financial health.

As you can see, these core benefits aren't isolated; they're interconnected results that all stem from a single, well managed system.

Choosing the right technology depends entirely on what you're tracking and where. A simple barcode might be perfect for low cost consumables, while RFID is a game changer for high value surgical trays or mobile equipment that tends to wander off. The key is to match the tool to the job.

| Technology | How It Works | Best For | Pros | Cons |

|---|---|---|---|---|

| Barcodes | A scanner reads a visual, line of sight code to identify an item. | High volume, low cost consumables like gloves, gauze, and basic supplies. | Very low cost per tag; simple and widely understood technology. | Requires direct line of sight; one at a time scanning; can be labor intensive. |

| RFID | Radio waves read data from a tag, often without a direct line of sight. | High value surgical trays, mobile medical equipment, and bulk inventory counts. | Bulk scanning saves time; no line of sight needed; enhances asset tracking. | Higher tag and reader cost; potential for signal interference. |

| Smart Cabinets | Secure, automated dispensing units that track item removal via user ID. | High cost medications, implants, and controlled substances. | 24/7 item level accountability; reduces theft and loss; automates reordering. | Higher initial investment; limited to items stored within the cabinet. |

Ultimately, a blended approach often works best. You can use barcodes for the everyday stuff and reserve RFID or smart cabinets for the items that pose the biggest financial or clinical risk if they go missing.

The Software Powering Your Operations

If the hardware components are the senses, the software is the brain. It takes the massive amount of data collected by scanners and readers and turns it into actionable information your team can actually use.

At the core is a central database, which serves as the single source of truth for every piece of inventory information. Building this requires a solid foundation; looking into data architecture best practices can help ensure you design a system that's both scalable and reliable. On top of this database, several key software modules do the heavy lifting:

- Analytics and Reporting Dashboards: These tools turn raw numbers into clear, visual reports on inventory levels, usage trends, and spending patterns. This is what helps you forecast demand with much greater accuracy.

- Integration Modules: A critical piece of the puzzle is the software’s ability to talk to other hospital systems, like your Electronic Health Record (EHR) and procurement platforms. This is how you ensure data flows seamlessly across departments without manual entry.

- Asset Tracking Software: Specialized platforms, like advanced asset tracking software, are designed specifically to monitor high value, mobile equipment, ensuring those critical assets are always where they need to be when a patient's health is on the line.

The impact of this technology is undeniable. A 2023 industry survey found that hospitals using RFID and barcode solutions saw their inventory accuracy jump from a shaky 60 to 70% to over 95%. This directly led to a 15 to 25% annual reduction in expired supplies and an 18% drop in lost equipment, proving the direct financial payback.

Tangible Benefits of Optimized Inventory Management

Putting a modern hospital inventory management system in place isn't just about adopting new tech. It's a strategic move that delivers a powerful return on investment, felt in every corner of your facility. The real value isn't found in a list of software features, but in the tangible financial and operational gains that come next.

These benefits add up to a stronger, more resilient healthcare operation. From the supply closet all the way to the C suite, the impact is clear, measurable, and essential for long term stability.

Slashing Costs and Eliminating Waste

One of the first and most significant advantages you'll see is a direct drop in costs. Let's be honest: manual inventory processes are notoriously inefficient and create hidden financial drains that add up faster than you'd think. A solid system plugs these leaks for good.

For example, automated tracking all but wipes out waste from expired supplies. By enforcing a strict "first in, first out" (FIFO) protocol, the system makes sure older stock gets used before it becomes unusable. This one change can save a facility thousands of dollars every year.

A well implemented hospital inventory management system stops financial bleeding. It transforms your supply chain from a source of unpredictable expenses into a tightly controlled, cost effective asset.

Beyond that, an intelligent system drastically cuts down carrying costs. Overstocking ties up valuable capital in products that are just sitting on a shelf. Data driven forecasting allows you to hold just the right amount of inventory, freeing up cash for other critical needs. It also helps you sidestep the premium prices you pay for last minute, emergency orders when a critical item runs out unexpectedly.

Boosting Operational and Clinical Efficiency

The direct savings are huge, but the massive boost in operational efficiency is just as critical. When clinicians aren't forced to spend their valuable time hunting for supplies or doing tedious manual counts, they can dedicate that time to what really matters: patient care.

This isn't a minor convenience; it's a fundamental shift in daily workflow. Nurses and technicians get critical minutes back in their day, which reduces stress and improves their ability to deliver high quality care. This efficiency also extends to the supply chain team, who can finally manage procurement and distribution proactively instead of constantly putting out fires.

Enhancing Patient Safety and Care Quality

Ultimately, the most important benefit of a hospital inventory management system is its profound impact on patient safety. Having the right sterile supplies, medications, and devices on hand at the exact moment they are needed is non negotiable. A stockout of a critical item during a procedure isn't just an inconvenience, it's a serious patient risk.

Automated systems provide the assurance that clinical teams need to do their jobs safely and effectively. This reliability is especially critical for high value items and controlled substances, where precise tracking is paramount. Technologies like intelligent vending solutions provide item level accountability, ensuring every critical component is tracked from the stockroom right to the point of care.

Digital tools are accelerating these gains across the healthcare industry. By 2025, industry data indicates that over 70% of hospitals in developed regions will have adopted IoT connected inventory systems. Facilities using predictive analytics are reporting reductions in emergency stockouts by up to 40% and decreases in overstocking by 20 to 35%. You can explore more data on how these tools are changing operational metrics in hospitals and see the full impact for yourself.

When you connect the dots between inventory availability and clinical outcomes, it becomes clear this technology is a strategic investment in both your hospital's financial health and its core mission. Ready to explore a solution? Call (800) 326-4403 for a free consultation.

Pairing Your System with Smart Physical Storage

An advanced digital hospital inventory management system is brilliant, but it can only perform as well as the physical environment it’s tracking. Think of it like this: the world’s best navigation app is useless if your car is stuck in a terribly designed parking garage. The software gives you the intelligence, but your physical storage provides the structure to actually execute on that intelligence.

This is where software and steel come together. An intelligent storage design is the true foundation of inventory accuracy, turning abstract data points into a tangible, organized reality. Without it, even the most sophisticated system will fight a losing battle against real world chaos, leading to misplaced items, inefficient workflows, and frustrated staff.

Maximizing Space and Enforcing Workflow

The first goal of smart storage is to squeeze the most out of every square foot. Hospitals are perpetually short on space, and a disorganized stockroom is often the main culprit behind waste. This is a problem that high density shelving and modular casework were born to solve, dramatically increasing your storage capacity within the exact same footprint.

But it’s not just about cramming more stuff in. The right layout naturally enforces critical inventory protocols.

- First In, First Out (FIFO): Properly designed shelving systems literally guide staff to pick older items first, a non negotiable for reducing spoilage of supplies with expiration dates.

- Logical Grouping: Putting related items together streamlines the picking process, saving clinicians precious time when they need to gather supplies for a procedure.

- Clear Visibility: Open shelving and clear bins make it easy for staff to see what they have at a glance, slashing the time they spend hunting for a specific item.

This structured approach transforms a cluttered supply closet into a high efficiency hub. For a deeper look at creating an optimal layout, check out our expert guidance on hospital stock room design.

Securing High Value Assets

Hospitals are responsible for a huge range of high value assets, from pricey surgical implants to controlled substances. Just leaving these items on open shelves is a massive financial and regulatory risk. This is where your physical security and digital tracking have to work in perfect sync.

Secure wire cages offer a tough, practical solution. They create a controlled access area right inside your existing stockroom, protecting your most valuable inventory. When you integrate this with your management system, every time that cage door opens or closes, it’s logged against a user ID, creating a complete and auditable chain of custody.

Smart physical storage is the essential bridge between digital inventory data and real world operational control. It provides the framework that makes your software’s commands possible, accurate, and secure.

This blend of a physical barrier and a digital log is fundamental for loss prevention and compliance. It ensures your high cost items aren't just a number on a screen, they are physically protected from theft or unauthorized access.

Extending Control to the Point of Care

Inventory control can't just stop at the stockroom door. That "last mile" of the supply chain, from central supply to the patient's bedside, is often where items go missing. Strategically placed mobile carts and modular workstations extend the reach of your hospital inventory management system right to the point of care.

These mobile solutions are like mini, decentralized supply stations. You can stock them with procedure specific supplies and roll them exactly where they're needed, making sure clinicians have everything required without ever leaving the patient area. This doesn't just improve efficiency; it also cuts down on the chances of supplies getting misplaced while being moved between departments. By making the right supplies immediately accessible, you empower your clinical team to focus on patient outcomes, not logistics.

A Practical Implementation Checklist for Your Facility

Switching from an old manual process to a new hospital inventory management system can feel like a monster of a project. But if you break it down into clear, manageable phases, what seems overwhelming becomes a straightforward process. This is the practical roadmap that sets you up for success right from the start.

A successful rollout isn't just about the tech. It's about getting your people, your processes, and your physical space all pulling in the same direction. By following a structured plan, you build confidence across the board and make sure your new system actually delivers on efficiency, cost savings, and patient safety.

Phase 1: Planning and Assessment

First things first: you have to build a solid foundation. This initial phase is all about getting a brutally honest look at where you are now and defining exactly where you need to be. Rushing this stage is a classic mistake that leads to mismatched expectations and expensive fixes down the road.

Start by pulling together a cross functional project team. This isn't just an IT or supply chain project; you need people from nursing, pharmacy, IT, and finance in the room. Their different perspectives are gold for spotting the real pain points and ensuring the solution you choose will actually work for everyone.

Next, get sharp on your goals. Is the number one priority to slash waste from expired supplies? Or maybe it's to finally get a grip on high value assets? Perhaps it’s all about freeing up your clinical staff's time. Setting specific, measurable goals will be your north star for every decision that follows.

A foundational step in any successful inventory management project is to thoroughly understand your existing assets. Learn how to perform a comprehensive asset audit to create a detailed baseline of your current inventory landscape.

Phase 2: Vendor Selection and Physical Layout

With your goals locked in, you can start looking at vendors. But just as important, and this is a critical mistake people make, you need to plan your physical storage at the same time. Picking software without thinking about how it works in your real world space is a recipe for disaster. A great system paired with a chaotic stockroom just doesn't work.

This is the perfect moment to bring in an expert who gets both inventory systems and physical storage design. We provide free layouts and designs with no obligation, helping you see exactly how high density shelving, secure cages, and mobile carts can streamline your workflow before you spend a dime on equipment. This guarantees your physical setup will fully support your new digital system.

Phase 3: Go Live and Training

This is where the rubber meets the road. The "go live" phase is all about moving your data from the old system (or those endless spreadsheets) to the new one and rolling out the hardware and software. Kicking things off with a phased rollout, maybe starting with a single department or one type of supply, is often the best way to minimize disruption.

And let's be clear: comprehensive staff training is completely non negotiable. Your team has to feel comfortable and confident with the new tools from day one. Good training is always role specific, showing each person exactly how the system is going to make their specific job easier and more efficient.

Phase 4: Optimization and Review

Flipping the switch isn't the finish line. The final phase is really a continuous loop of monitoring what’s happening, getting feedback from users, and making smart, data driven tweaks.

Use the system’s analytics to track your key performance indicators (KPIs) and see how they stack up against the goals you set back in Phase 1. This ongoing review is how you fine tune workflows, adjust stock levels, and truly unlock every bit of value from your investment.

Ready to start planning your facility's transformation? Request a Quote to get started with a free, expert led layout design.

What's Next for Hospital Inventory Management?

The world of hospital inventory management is anything but static. Technology is pushing the envelope, promising greater efficiency, smarter forecasting, and pinpoint accuracy. If you're a facility manager or buyer, keeping an eye on these trends isn't just about staying current, it's about making a future proof investment.

These aren't far off concepts from a sci fi movie; they are the next wave of tools that will define what operational excellence looks like in healthcare. The goal is to shift from reactive ordering to a supply chain that's predictive, intelligent, and always one step ahead.

AI and Machine Learning for Predictive Forecasting

One of the biggest game changers is the arrival of Artificial Intelligence (AI) and machine learning. Think of it as giving your inventory system a crystal ball. These technologies crunch massive datasets to spot patterns that are simply invisible to the human eye.

Imagine a system that sees public health data on flu outbreaks, cross references it with seasonal trends and your own hospital's admission history, and then automatically predicts a spike in demand for IV fluids and antiviral medications. That’s what we’re talking about.

This kind of predictive power lets hospitals:

- Anticipate Needs: Proactively stock up for known events, like flu season or large scale scheduled surgeries, before the rush hits.

- Slash Overstock: Move away from outdated "par levels" and order exactly what you'll need, minimizing the cash tied up in excess inventory.

- Prevent Stockouts: Ensure the most critical supplies are always on the shelf, even during an unexpected surge in patient volume.

This turns your inventory system from a simple record keeper into a strategic forecasting powerhouse, directly impacting both your budget and your ability to care for patients.

The Rise of IoT and Robotics

The Internet of Things (IoT) is another trend picking up serious steam. This is all about embedding smart sensors into everything from vaccine refrigerators to IV pumps and surgical kits. These tiny devices feed you real time data on an item's location, status, and even its environment.

The next generation of inventory management isn't just about knowing what you have; it's about your system knowing what you will need and ensuring it's in the right place, at the right temperature, at the right time.

For instance, an IoT sensor can continuously monitor the temperature of sensitive biologics, shooting off an instant alert if the conditions drift even slightly out of the safe zone. This simple function prevents thousands of dollars in spoilage and, more importantly, guarantees that medications are effective when they reach the patient.

Working alongside IoT, robotics is starting to handle the grunt work: picking, packing, and delivering supplies around the hospital. This frees up your highly skilled clinical staff to focus on what they do best: patient care.

The demand for these advanced systems is exploding. One forecast valued the global hospital asset tracking and inventory management market at roughly $30.25 billion in 2024, and it's projected to climb to nearly $42.9 billion by 2029. You can dig into more insights on this significant market growth and what's driving it. This growth makes one thing clear: the entire industry is moving toward a smarter, more automated future.

Ready to Optimize Your Hospital's Inventory?

A modern hospital inventory management system, paired with an intelligent physical storage layout, isn't just a "nice to have" anymore. It's the backbone of a hospital that wants to control costs, work more efficiently, and guarantee patient safety. We've walked through how the right blend of technology and infrastructure can turn your supply chain from a reactive cost center into a strategic asset.

Now, it’s time to put that knowledge into action.

Let our team's experience help you build a solid foundation for your project. We offer free, no obligation layout designs, so you can see exactly how to make the most of your space before spending a dime. It's the perfect first step, backed by the fastest shipping in the industry and competitive pricing on top quality storage solutions.

We're here to help you design a system that truly works, one that cuts down on waste and frees up your clinical team to focus on what they do best: patient care. It's time to stop letting outdated processes dictate your hospital's potential.

Ready to build a more efficient and secure supply chain?

Contact Us today to talk about your project, or Request a Quote to get a complimentary layout design from our experts.

Answering Your Key Questions

Thinking about a new hospital inventory management system is a big step, and it's natural to have questions. Let's tackle some of the most common ones we hear from hospital managers and clinical leaders.

How Long Will This Take to Implement?

This is always a top of mind question. Realistically, you should plan for a project timeline of three to nine months. We strongly recommend a phased rollout to avoid disrupting patient care.

The first one to two months are all about planning, assessing your current state, designing the physical layout, and getting the infrastructure right. After that, bringing a single department live and getting everyone trained usually takes about another month. From there, you can roll out to other departments over the following quarters. This approach keeps things manageable and ensures each team is confident before the next one starts.

How Do We Measure the Return on Investment (ROI)?

Tracking your ROI is non negotiable. It’s how you prove the project's value. The key metrics you absolutely need to watch are:

- Expired Supply Waste: How much money are you saving by not throwing away expired items? This is a direct, hard dollar saving.

- Inventory Carrying Costs: Track the reduction in overstocked supplies. Less cash tied up on shelves is a huge win.

- Inventory Turnover Rate: A faster turnover rate shows you’re using your stock much more efficiently.

- Emergency ("STAT") Orders: A drop in last minute, expensive orders means your forecasting and planning are actually working.

The whole point is to shift your supply chain from being a cost center to a real strategic advantage. With a well executed system, you should start seeing a positive ROI within 12 to 18 months, mainly from cutting waste and boosting efficiency.

How Do We Get Staff to Actually Use the New System?

This is the make or break question. The best tech is useless if your team won't adopt it. The secret is to get your clinical staff involved from the very beginning. Don't wait until you're ready to install it.

Frame it as a tool that solves their biggest frustrations, not as another administrative headache. Show them how it eliminates the time they waste hunting for supplies, giving them more time for patient care. Follow that up with thorough, role specific training that speaks directly to their daily challenges. When they see it as a solution to their problems, buy in happens naturally.

Ready to build a more efficient and secure supply chain for your facility? The team at Material Handling USA offers free, no obligation layout designs to help you pair the right physical storage with your management system.

Request a Quote today or Contact Us to speak with an expert.