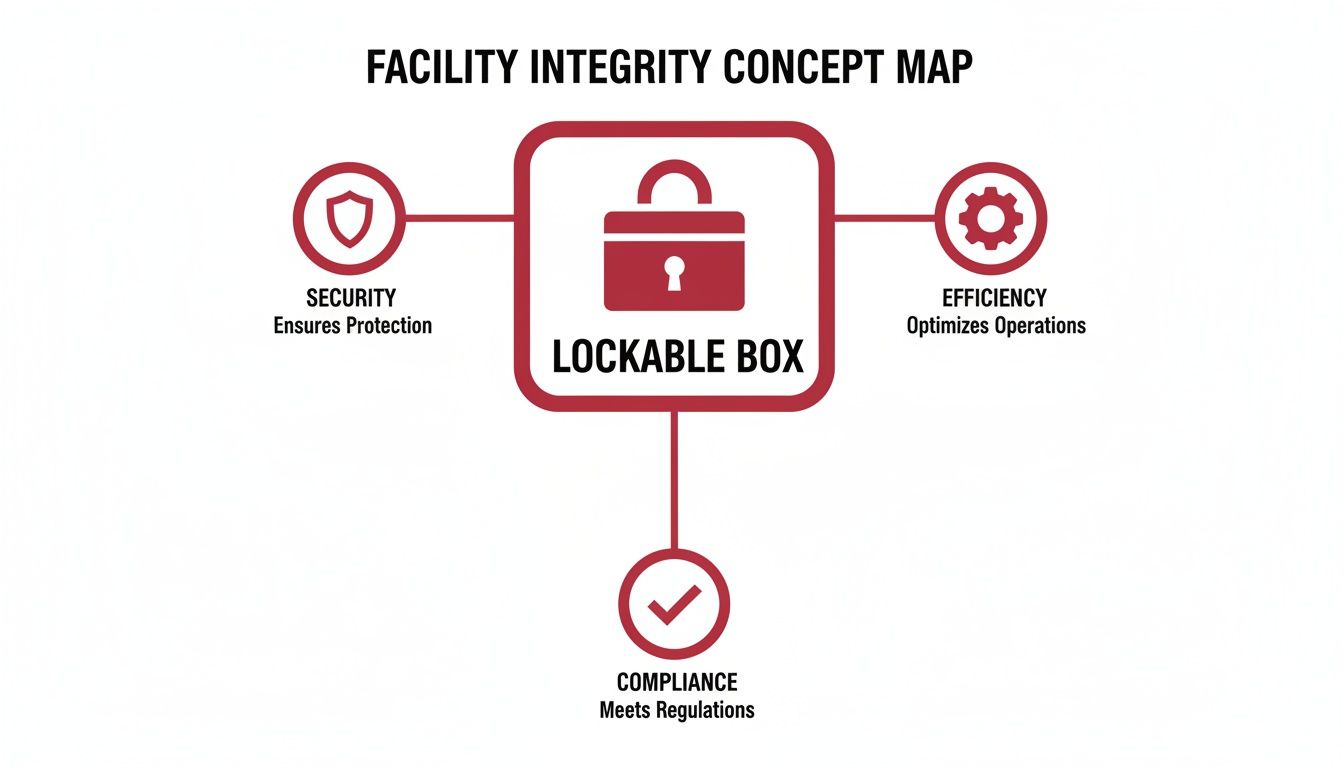

At its core, a lockable storage box is a secure container designed to keep assets safe from theft, damage, and unauthorized access in tough commercial and industrial settings. But thinking of it as just a "box" misses the point. It is a strategic tool for keeping your operations running smoothly, efficiently, and in compliance.

The Foundation of Facility Security and Efficiency

In any professional operation, protecting your assets is the bedrock of stability. A lockable storage box acts as your first line of defense, safeguarding everything from high-value tools on a factory floor to irreplaceable evidence in a law enforcement agency. When you move past basic bins and tubs, the right secure storage solution becomes a fundamental part of your workflow.

Figuring out and implementing robust theft protection strategies is non-negotiable for securing valuable assets. Getting these solutions integrated correctly from the start prevents logistical headaches down the road, minimizes asset loss, and makes daily operations a whole lot smoother.

Securing Assets in a Growing Market

The need for secure storage is not just an observation, it is a major market trend. The tool box market, which includes the durable, lockable containers used in warehouses and on job sites, is seeing significant growth. Industry analysis projects this market will balloon from USD 13.4 billion in 2026 to USD 29.5 billion by 2036. This massive jump shows just how critical these solutions are in industries like construction, automotive, and manufacturing, where managers rely on them to protect expensive equipment. You can read the full research about these market trends from Future Market Insights.

This growth is a clear signal that managers everywhere are recognizing that unsecured assets are a liability waiting to happen. By planning for secure storage now, you are not just buying a box. You are aligning with industry best practices and avoiding the operational drag that comes from inventory shrinkage and misplaced gear.

Why Proactive Planning Matters

Making an informed decision on secure storage is not just a purchase; it is a proactive step toward a more organized and protected facility. The benefits go far beyond just locking something up.

- Improved Workflow: When your team knows exactly where to find tools and supplies, they spend less time searching and more time working. It is a direct boost to productivity.

- Enhanced Accountability: Designated, lockable containers create a clear system of ownership and accountability, which drastically reduces accidental loss or misplacement.

- Operational Readiness: Critical equipment that is secure, organized, and ready to go prevents delays and keeps projects on schedule. No more last minute hunts for a crucial part.

Thinking through your facility’s needs today leads to better planning, faster installations, and a setup that is ready for future demands. To see how a custom layout could optimize your space, Request a Quote and connect with one of our design experts.

Choosing the Right Materials for Your Environment

A lockable storage box is only as good as what it is made of. When you are picking one out, you are not just looking at durability; you are matching the container to the real world stresses of your facility. This is how you make sure your assets stay secure and the box itself lasts for years.

The material a box is made from directly affects how it stands up to impacts, corrosion, and tampering. Will it face the daily grind of a busy warehouse, the dampness of an outdoor site, or the strict cleanliness standards of a lab? The right material makes all the difference.

Think of it this way: a lockable box is not just a container. It is a core piece of your operational puzzle, connecting security, efficiency, and compliance to keep your entire facility running smoothly.

This simple idea highlights how the right box becomes a central tool for maintaining a well managed system, not just a place to put things.

Comparing Common Storage Box Materials

Let us break down the most common materials you will find and see where each one really shines. Knowing the difference between them will help you make a practical decision based on what your operation actually needs.

Choosing the right material is a big decision, especially as more industries rely on secure containers to keep things running. The storage box market is set to hit $12.07 billion by 2035, and that growth is fueled by real world needs. In retail, lockable units help slash inventory shrinkage. For law enforcement, the right boxes can lead to a 50% improvement in maintaining the chain of custody. You can discover more insights about these market shifts on Business Research Insights.

To make the choice easier, here is a quick comparison of the top materials we see in the field.

| Lockable Storage Box Material Comparison | |||

|---|---|---|---|

| Material | Key Advantages | Best For | Considerations |

| Heavy-Gauge Steel | Maximum strength and tamper resistance. Its weight is a natural deterrent to theft. | High-value assets, stationary security in workshops, warehouses, and industrial sites. | Heaviest option, which limits portability. Susceptible to rust if the coating is compromised. |

| Lightweight Aluminum | Excellent strength-to-weight ratio. Naturally resistant to rust and corrosion. | Mobile applications (tool chests, transport boxes), outdoor use, and humid environments. | Can be more expensive than steel or polymers. May dent more easily than steel under heavy impact. |

| Durable Polymers | Tough, lightweight, and resistant to chemicals, moisture, and dents. Often the most cost-effective choice. | General-purpose storage, chemical handling areas, and situations where weight is a factor. | May offer less brute-force security against determined attacks compared to heavy-gauge steel. |

This table should give you a solid starting point. Each material serves a purpose, and the best one is simply the one that fits the job you need it to do.

Matching Box Design to Your Workflow

Beyond the material, the box's physical design has to fit seamlessly into your daily workflow. The right shape and size can save space, make things easier to get to, and give your team's efficiency a real boost.

Here are a few common designs to think about:

| Box Design | Primary Use Case | Key Advantage |

|---|---|---|

| Stackable Bins | Organizing small parts or inventory. | Maximizes vertical space on shelving units. |

| Mobile Chests | Transporting tools and equipment. | Offers portability with wheels and handles. |

| Wall-Mounted Cabinets | Storing supplies in tight spaces. | Frees up valuable floor space. |

| Under-Bed Boxes | Vehicle or low-profile storage. | Utilizes otherwise wasted space securely. |

The key is picking a design that works with your existing setup. For example, getting stackable bins that are a perfect fit for your current shelving creates an instantly organized and efficient system. If you are looking to build out that foundation, exploring options like our stainless steel shelving solutions can provide a clean, tough, and long lasting base to build upon.

The smartest storage solutions are those that feel like a natural extension of your workspace. The goal is to make security and organization effortless, not an obstacle.

Figuring out the perfect combination of material and design takes a bit of foresight. That is where our team comes in. Our experts offer free, no obligation layouts and designs to help you visualize the most effective solution for your facility. Just reach out, and we can start planning your setup together.

Navigating Locks and Security Features

The lock is really the heart and soul of any secure container. Getting a handle on the different mechanisms out there is the key to matching a lockable storage box with what you actually need it for. It is always a balancing act between locking things down tight and making sure your team can get their work done.

Think about it this way: a shared tool chest on a factory floor might just need a simple, heavy duty keyed padlock. Easy. But if you are storing high value electronics or controlled substances, you will want something like an electronic keypad that creates an audit trail, showing exactly who got in and when. Picking the right lock is all about taking a hard look at your specific risks.

A Breakdown of Locking Mechanisms

Every type of lock brings something different to the table. The trick is to pick the one that lines up with your facility’s access rules and security demands.

- Keyed Locks: These are the old school standard, offering reliable security with a physical key. You can find everything from basic padlocks to high security cam locks built right into the box. They are straightforward and get the job done, but you have to be on top of your key management.

- Combination Locks: These get rid of keys altogether, using a numeric code to grant access. They are perfect for situations where a few different people need access without the headache of handing out and tracking a bunch of keys.

- Electronic and Digital Locks: For a much higher level of control, these systems use a keypad for PIN entry. A lot of these models come with powerful features like audit trails, time delayed access, and codes for multiple users.

Choosing the right locking mechanism is about balancing security needs with operational access. A high-security area may benefit from an electronic lock with an audit trail, while a general tool chest might only require a robust padlock.

For operations that demand the absolute highest level of control and tracking, you might want to look at fully integrated solutions. You can get a better sense of how technology can ramp up access control by checking out our guide on smart locker systems.

The Growing Importance of Secure Access Control

Let us face it, secure key storage has become a non-negotiable part of modern business security. Lockable key boxes are now vital assets for everyone from commercial property managers to industrial facility supervisors. The global market for just these specialized boxes is expected to climb to USD 1.9 billion by 2033.

This is not just a random spike; it is being pushed by sectors from healthcare to law enforcement that need absolutely tamper proof solutions. We are also seeing new tech like fingerprint and Bluetooth enabled models boosting adoption by 15% to 25% in smart facilities, adding convenience without giving up an ounce of security.

This trend points to a bigger shift happening across all industries. As assets get more valuable and compliance rules get tighter, the need for smarter, more accountable security solutions is only going to grow.

Decoding Security Ratings and Certifications

When you see a security rating on a lockable storage box, it is not just marketing fluff. These certifications are a standardized way to measure how well a product can stand up to tampering and brute force.

| Common Security Certifications | What It Means for You |

|---|---|

| UL (Underwriters Laboratories) Ratings | This is a highly respected certification that means the product has been tested against specific attacks, like drilling or picking. A higher UL rating means it is tougher to break into. |

| IP (Ingress Protection) Ratings | This rating tells you how well a box resists dust and water. For example, an IP67 rated box is completely dust tight and can even be submerged in water. |

| CEN (European Committee for Standardization) Grades | You will often see this on padlocks. The grade (from 1 to 6) tells you the lock's security level against different kinds of attacks. A Grade 6 lock offers the highest security you can get. |

Understanding these ratings helps you make a solid, objective decision based on the real world threats in your environment. A manager in a dusty manufacturing plant should be looking for a high IP rating. Someone securing controlled substances, on the other hand, needs to prioritize top tier UL or CEN ratings. Getting this right ensures your investment works for your daily operations and satisfies any potential insurance requirements.

Our team can help you sort through these specs to find the perfect match for your application. Call 800-326-4403 to talk with one of our specialists.

Getting the Size and Integration Right

Picking the right material and lock is a great start, but it is only half the battle. A lockable storage box that is too small is useless, and one that is poorly placed can quickly become a safety hazard or an operational bottleneck. Getting the size and installation nailed down the first time is what turns a good purchase into a truly efficient and secure system.

This is not about just glancing at dimensions. It requires a hard look at both volume and, more critically, weight. A box might have plenty of room for your items, but if it cannot handle the load, you are risking structural failure and serious damage to your valuable assets.

Calculating Your True Storage Needs

Before you even think about buying a lockable box, you need to get an accurate picture of what you are storing. This goes way beyond just eyeballing a pile of equipment. A more methodical approach ensures you invest in a solution that works from day one.

Start by gathering everything you plan to store and group it all logically. You might be surprised. This simple exercise often shows you need more or less space than you first thought. Once everything is grouped, measure the collective dimensions to figure out the internal volume you will need.

But the most critical step is calculating the total weight.

Load capacity is a non-negotiable safety and performance metric. Overloading a storage box can lead to warping, lock failure, or a complete collapse, creating massive risks for your team and the assets inside.

Always choose a box with a load capacity that comfortably exceeds your calculated total weight. This builds in a crucial safety margin, which is especially important if the contents are likely to change over time.

Mounting and Installation Options

How and where you install your lockable storage box has a direct impact on its usefulness and your facility’s workflow. The right placement can make the most out of unused space, while the wrong one creates frustrating obstructions. Let us look at the most common installation strategies to see what fits your environment.

| Installation Type | Description | Ideal For |

|---|---|---|

| Freestanding | Placed directly on the floor without permanent fixtures. Often comes with wheels for mobility. | Workshops, garages, and any area where storage needs are dynamic and might have to be moved around. |

| Wall Mounted | Securely fastened to a wall, which gets the box completely off the floor. | Smaller facilities, cleanrooms, or anywhere that maximizing floor space is the top priority. |

| Vehicle Integrated | Designed to be permanently installed in service trucks, vans, or other commercial vehicles. | Field service techs, construction crews, and mobile teams who need secure storage on the go. |

| Shelving Integrated | Sized to fit perfectly within existing pallet racking or industrial shelving units. | Warehouses, stockrooms, and distribution centers looking to add secure storage into their current layout. |

Each option has its own clear advantages. A freestanding chest gives you flexibility, while a wall mounted cabinet can turn an empty wall into a secure storage hub. Proper planning is what unlocks these benefits without disrupting your operations.

The Power of Smart Integration

The best storage systems are the ones designed with integration in mind from the very beginning. Just dropping a random assortment of lockable boxes wherever they fit leads to a disorganized, inefficient workspace. Instead, think about how these secure units can become a natural part of your existing infrastructure.

For example, integrating a lockable storage box directly into your modular shelving or pallet racking is a fantastic move. This approach converts standard shelving into a high security zone without eating up any new floor space. It keeps valuable items locked down but still easily accessible to authorized staff right where they do their work.

Planning this kind of integration upfront is far more effective than trying to retrofit a solution later. With the supply chain delays and project backlogs we see across all industries, proactive planning is more critical than ever. Getting a professional layout and design early in the process helps you sidestep costly adjustments and keeps your project timeline from derailing. Our team offers free layouts and designs with no obligation, helping you visualize the optimal setup for your facility.

Ready to see how a professionally planned layout can improve your workflow? Request a Quote or call us at 800-326-4403 to talk through your project with an expert.

Tailoring Storage for Specific Industry Needs

A lockable storage box is not just a commodity you pick off a shelf. Its real value comes to life when it is perfectly matched to the unique grind of your industry. A heavy duty steel box designed for a warehouse floor would be wildly out of place in a sterile lab, and a lab grade container would not last a day on a busy loading dock.

By walking through some real world scenarios, you can start to see how a purpose built secure container directly impacts your daily workflow, security protocols, and overall efficiency. This shifts the conversation from a list of features to concrete benefits, making the decision much clearer for your team and your budget.

Warehousing and Logistics

In a buzzing warehouse or distribution center, the two biggest headaches are preventing theft of high value inventory and shielding sensitive equipment from damage. A general purpose plastic tote just will not cut it when you are trying to secure thousands of dollars in electronics or specialized tools.

This is where heavy gauge steel boxes become the standard. Their sheer weight and tough construction are a powerful deterrent right from the start. When you integrate these units directly into your pallet racking, you create controlled access points right in the middle of your workflow, letting managers secure critical items without slowing down picking and packing.

Key features for this sector include:

- High Load Capacity: Essential for safely storing heavy parts, tools, or bulk inventory without worrying about structural failure.

- Forklift Accessible Designs: Many larger boxes come with built in fork pockets, making it safe and efficient to move them anywhere in the facility.

- Reinforced Locking Points: Built to stand up to brute force attacks and designed to accommodate high security padlocks or hasps.

Law Enforcement and Evidence Storage

For police departments, the number one priority is maintaining an unbroken chain of custody. A lockable box here is not just about security. It is a critical tool for guaranteeing evidence integrity from the crime scene to the courtroom. Any weak link in that chain can jeopardize an entire case.

Evidence boxes have to be tamper evident and often need locking mechanisms that provide a full audit trail. An electronic keypad lock that logs every single time it is opened is invaluable, giving you a clear record of who accessed the contents and when. Of course, they also need to be tough enough to protect sensitive items during transport and long term storage.

In legal and forensic settings, the storage container itself is part of the evidentiary process. Its ability to provide verifiable, documented security is as important as its physical strength.

This is why so many agencies are shifting to solutions that offer more than just a physical key. Digital access control delivers the accountability needed to meet strict legal standards. The demand for systems with verifiable access logs is only growing, so planning for them now can prevent future compliance headaches or the need for expensive upgrades.

Healthcare and Laboratory Environments

In medical and lab settings, the game changes. The focus shifts to preventing contamination, controlling access to sensitive materials, and complying with a mountain of regulations. Here, a lockable storage box might hold controlled substances, patient samples, or priceless research materials.

Stainless steel or chemical resistant polymer boxes are perfect for these clean environments. They are non-porous, a breeze to sanitize, and will not react with harsh cleaning agents or spilled chemicals. For extremely sensitive materials, you can even find refrigerated or insulated lockable boxes to maintain specific temperatures. And for facilities that handle a wide range of substances, you can learn more about our solutions for safe chemical storage.

Retail and Agriculture Applications

In retail, backroom stock and high value merchandise are constant targets for both internal and external theft. Lockable, mobile chests give managers a way to secure items like electronics or jewelry and then easily roll them from the stockroom to the sales floor. These units usually feature durable casters and multiple locking points for added security.

Even out in the field, secure storage is a necessity. Farmers and ranchers need to protect expensive tools, chemicals, and supplies from theft and the elements. Specialized containers, like a Compact Front Box for Wrap and Twine, show just how tailored a solution can be, keeping essential supplies organized and secure exactly where they are needed most.

Ultimately, the right lockable storage box is a specialized tool. Once you identify the core challenges of your industry, whether it is chain of custody, inventory shrinkage, or contamination control, you can pick a solution that delivers real, tangible results.

Finding Your Ideal Storage Solution with Expert Help

You have done the homework. You know what goes into choosing the right lockable storage box. Now it is time to put that knowledge to work. The whole process really boils down to getting a few key things right: picking the right material for your environment, matching the security level to the assets you are protecting, and nailing the size and load capacity. Getting these decisions right from the very beginning is the difference between a smooth operation and a costly headache.

Working with a storage expert means you are getting more than just a box off a shelf. You are getting a complete solution that is actually built around your space, your workflow, and your budget. That guidance is most valuable in the early planning stages, long before a single bolt is turned.

The Value of Proactive Planning

With the current demand for industrial gear, planning ahead is no longer just a good idea. It is essential. Taking the time to map out what you need now helps you lock in better timelines and sidestep the kind of installation delays that can throw a wrench in your entire operation. A well thought out plan is your best defense against expensive mistakes and blown deadlines.

We cannot recommend this enough: take advantage of services like our no obligation, free layouts and design consultations. It is the best way to get a crystal clear picture of how the final setup will look and function in your actual space. This takes all the guesswork out of the process and ensures everything fits perfectly with your existing setup.

Your Next Steps Checklist

Ready to move forward? Use this simple checklist to keep your decision making on track.

- Figure out your exact security needs. What is the total value of the inventory you need to protect?

- Break out the tape measure. Get precise measurements of your available space and calculate the volume and weight capacity you will need.

- For standard needs, browse our online store for lockable storage box solutions that are in stock and ready to ship.

- For anything custom or for larger projects, reach out to our experts for a free quote and a complete layout design.

Whether you just need a single, tough as nails box right now or you are gearing up for a full facility overhaul, our team is here to make sure it all goes off without a hitch. For standard solutions, you can Buy Online today and get the benefit of the fastest shipping in the industry. For more complex projects, Contact Us at 800-326-4403 to kick off your free design consultation.

Your Questions Answered: Lockable Storage Boxes

When you are ready to secure your assets, a few questions always come up. Here are the straight answers to some of the most common things we hear from customers, helping you clear up any final details before you make a decision.

What is the Single Most Important Factor When Choosing a Lockable Box?

While things like durability and size are obviously important, it really boils down to this: align the locking mechanism with the value and sensitivity of what you are storing.

A simple key lock on a box for general office supplies is one thing. But a box holding controlled substances in a lab, high value electronics in a warehouse, or critical evidence? That is a completely different ballgame. Always start by thinking about the specific risk and any compliance rules you have to follow.

Are Plastic Lockable Boxes Really Secure Enough for Industrial Use?

Absolutely. Do not let the word "plastic" fool you. We are talking about high density, industrial grade polymer boxes that are incredibly tough. They offer fantastic resistance to impacts, moisture, and even chemicals, and they are often lighter and more cost effective than metal.

For many industrial jobs, a top quality polymer box with a solid locking system is more than enough. However, if you are dealing with extreme security needs or a high fire risk, a heavy gauge steel box is still the go to recommendation.

How Can I Fit These into My Existing Warehouse Shelving?

Good news. Most professional grade lockable storage boxes and bins are designed with standard dimensions to slide right into existing pallet racking and industrial shelving systems.

To make sure you get a perfect, seamless fit, it is always best to have a design specialist take a look.

We offer free layout and design services to ensure your new secure storage integrates perfectly with your current setup. This helps you maximize every inch of space and, more importantly, avoids costly mistakes or project delays down the road.

What Kind of Maintenance Do These Boxes Require?

Thankfully, it is pretty minimal. For any box, a regular wipe down to get rid of dust and debris is a good habit.

If you have metal boxes, especially in damp environments, give them a once over periodically to check for any signs of rust and tackle it early. The most important thing is to regularly inspect the locking mechanism itself. Make sure it operates smoothly. A little lubricant on the hinges and lock components, based on the manufacturer's advice, can make a huge difference in the life and reliability of the box.

At Material Handling USA, we do not just sell products; we deliver complete storage solutions. Every order is backed by expert design, quality materials, and the fastest shipping in the industry. Whether you need an off the shelf solution or a completely custom layout, our team is here to get it done.

Contact Us or call 800-326-4403 for a free, no obligation quote.