A heavy-duty roller conveyor is engineered for one simple reason: to move serious weight, reliably and repeatedly. Unlike their standard-duty cousins, these systems are built from the ground up with thicker gauge steel frames, larger diameter rollers, and industrial-grade bearings. They're designed to handle the relentless punishment of manufacturing floors, warehouses, and distribution centers.

These conveyors are the unsung workhorses of industry, forming the essential backbone for moving everything from fully loaded pallets and steel drums to bulky, awkward industrial components. When operational downtime is not an option, a robust conveyor system is a strategic necessity.

What Defines a Roller Conveyor as Heavy-Duty?

Think of the difference between a standard pickup truck and a full-blown semi-trailer. Both haul cargo, but only one is built to handle massive, continuous loads day in and day out. That's exactly the role a heavy-duty roller conveyor plays in your facility. But what really separates these systems from lighter-duty options? It all comes down to a few deliberate engineering choices in their core components.

The strength of any system starts with its foundation. For a heavy-duty conveyor, that foundation is a high-gauge steel frame, often 10 gauge or thicker, specifically designed to resist twisting and bending under extreme weight. This rock-solid structural integrity is what ensures the conveyor stays aligned and performs flawlessly over years of hard service.

Core Components Built for Strength

The rollers themselves are a critical differentiator. They boast larger diameters, typically 1.9 inches to 3.5 inches or even more, which creates a bigger contact area to better distribute the load. This is paired with industrial-grade, precision bearings that are sealed to keep out dust and debris, ensuring smooth operation even in the grimiest environments.

The drive system is another key piece of the puzzle. The power source is fundamental to its heavy-duty classification, with powerful three and single phase electric motors providing the necessary muscle for sustained performance. In powered systems, this motor drives heavy-gauge chains or rugged belts to provide positive, non-slip movement for even the heaviest loads.

Key Takeaway: A conveyor is not "heavy-duty" just because it is big. It is the specific combination of a robust frame, large-diameter rollers, industrial bearings, and a powerful drive system that allows it to handle significant loads day after day without failing.

The Growing Demand for Durable Conveyors

The importance of these rugged systems is showing up in market trends. The global roller conveyor market is expected to climb from $2.67 billion in 2021 to over $3.56 billion by 2025. This growth is fueled by logistics and manufacturing sectors that desperately need durable, high-capacity solutions to keep up. It is a clear sign that facilities are investing in reliable infrastructure to meet crushing operational demands.

Upgrading to a purpose-built heavy-duty system is more than a purchase; it is a strategic investment in your operational stability. By choosing equipment actually designed for your specific loads, you slash the risk of breakdowns, reduce dangerous manual handling, and create a workflow that is both safer and far more productive.

Choosing The Right Type of Heavy Duty Conveyor

Picking the right heavy-duty roller conveyor is not just a small detail—it is a critical decision that directly shapes your workflow. The choice you make impacts everything from operational efficiency and product safety to your long-term return on investment. It all comes down to matching the conveyor's core function to what you actually need to do.

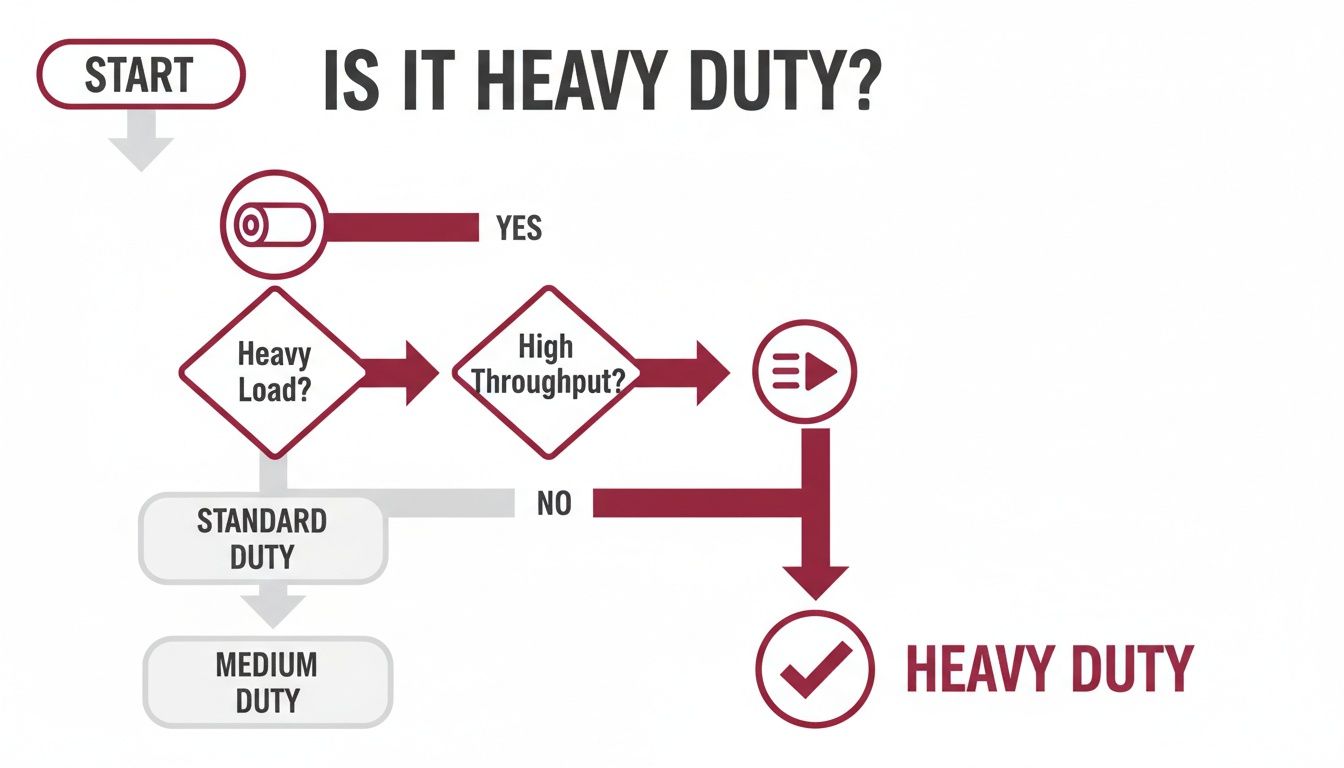

This flowchart helps visualize how your load requirements and throughput demands point toward a heavy-duty solution.

As you can see, when heavy loads meet the need for high throughput, investing in a heavy-duty system becomes a clear operational advantage. Let us dig into the three main players you will be choosing from.

Gravity Roller Conveyors: The Cost-Effective Workhorse

Think of gravity roller conveyors as the simplest, most reliable workhorse in your facility. Just like the name implies, they use gravity (a slight decline) or a manual push to get items from point A to point B. They are incredibly versatile and have almost no maintenance needs, making them a fantastic starting point for many operations.

You will typically see them in action at loading and unloading docks, for moving items short distances between workstations, or in basic assembly lines. Because there are no motors or complex electronics, they are exceptionally dependable and a breeze to install. Their main limitation? They are not built for moving items up an incline or for jobs that require precise speed control.

Chain Driven Live Roller (CDLR) Conveyors: For Uncompromising Power

When you are dealing with seriously heavy, awkward, or just plain difficult loads, the Chain Driven Live Roller (CDLR) conveyor is the undisputed champion. These brutes use a motor and a roll-to-roll chain drive that positively powers every single roller. Nothing is going to stop your product from moving forward.

This powerhouse design makes CDLR the go-to for handling pallets, drums, large castings, and other bulky unit loads. They truly shine in tough industrial settings where oil, debris, or uneven products would make other conveyors fail. The positive chain drive means no slippage—just consistent, reliable movement for your most demanding applications.

Zero Pressure Accumulation (ZPA) Conveyors: The Smart Solution

On the more advanced end of the spectrum, you will find Zero Pressure Accumulation (ZPA) conveyors. These systems are engineered to transport and queue up products without ever letting them touch. They do this by breaking the conveyor line into independent zones that can intelligently start and stop based on product flow.

This "zero-contact" buffering is absolutely essential for protecting fragile or high-value items from getting damaged while they wait in line. ZPA systems are a cornerstone of modern automated warehouses, perfectly feeding sortation systems, robotic palletizers, or packaging stations. While they come with a higher upfront cost, the product protection and intelligent workflow they create deliver immense value in complex operations.

To make things a bit clearer, here is a quick side-by-side look at the most common types of heavy-duty roller conveyors.

Heavy Duty Roller Conveyor Type Comparison

| Conveyor Type | Power Source | Best For | Key Advantage |

|---|---|---|---|

| Gravity Roller | Manual / Incline | Loading/unloading, short-distance transport, simple assembly. | Cost-effective, simple, no power required. |

| Chain Driven Live Roller (CDLR) | Motor & Chain | Pallets, drums, oily environments, heavy unit loads. | Positive drive, handles extreme loads, durable. |

| Zero Pressure Accumulation (ZPA) | Motorized Rollers / Zones | Buffering products, preventing collisions, automated lines. | Protects fragile items, smart zone control, high-tech. |

Understanding these key differences is the first step toward a successful integration. Gravity offers simplicity and value, CDLR provides raw power for the toughest jobs, and ZPA delivers intelligent control for automated environments.

Navigating these options can feel overwhelming, but our team is here to help. We provide free, no-obligation layouts to help you visualize the perfect system for your space. With our expertise, you can confidently select a heavy duty roller conveyor solution that meets your needs today and scales with you tomorrow. Explore our full range of conveyor systems to see what is possible.

Getting Your Conveyor Specs Just Right

Trying to order a heavy-duty conveyor system without nailing down the specifications is like building a bridge without blueprints. Even a small miscalculation can create massive operational bottlenecks, cause premature wear and tear, or lead to a complete system failure. This guide is your practical checklist to get it right the first time, helping you avoid costly mistakes and lock in long-term reliability.

First, let us get a handle on the technical details. The global conveyor market is booming, expected to jump from USD 12.6 billion in 2025 to USD 20.3 billion by 2035, and roller conveyors are leading the charge because of how tough and versatile they are. This growth is all about facilities in North America and beyond needing precisely engineered systems to hit the 15-25% throughput gains that modern logistics demand. You can learn more about these conveyor market trends to see why getting the specs right is absolutely non-negotiable.

Load Capacity and the "Single Heaviest Item" Rule

The most crucial spec, hands down, is load capacity. A classic mistake we see is calculating this based on an average load weight. This is a huge gamble. Your heavy-duty roller conveyor absolutely must be engineered to handle the single heaviest item that will ever roll across it, with a healthy safety margin built in.

Basing your capacity on an average is a recipe for disaster. It completely ignores the peak loads that will inevitably push your system to its limits. Designing for the heaviest possible item ensures the frame, rollers, and supports can take the maximum stress at any given moment without breaking a sweat.

Expert Insight: Always, always design your conveyor around the maximum unit load, not the average. This one principle is the single most important factor in guaranteeing the safety, reliability, and longevity of your material handling system.

Roller Diameter and Spacing

The size of your rollers and the space between them are just as important. For heavy-duty jobs, roller diameters typically range from 1.9" to 3.5". It is simple, really: a larger diameter gives you more surface area and can support more weight.

Roller spacing—the distance from the center of one roller to the center of the next—is all about how well your products are supported as they move. This brings us to a foundational concept in conveyor design: the "three roller rule."

The Three Roller Rule:

To keep things moving smoothly and stably, the smallest item you're conveying must rest on at least three rollers at all times. Sticking to this rule is the key to preventing products from tipping over, getting jammed between rollers, or sagging, all of which can grind your entire operation to a halt.

Between Frame Width and Frame Gauge

Between Frame (BF) Width is the usable conveyor surface, measured from the inside of one frame rail to the inside of the other. Figuring this out is straightforward: measure the widest load you will ever convey and then add a couple of inches on each side for clearance. That little bit of extra room ensures products move freely without scraping the frame, which can cause damage or jams.

The frame itself is the conveyor's backbone. Its strength is determined by the frame gauge, which is just the thickness of the steel. For any serious heavy duty roller conveyor application, you will want a thicker gauge, like 10-gauge steel. This provides the structural integrity needed to handle immense loads without flexing or bowing over time.

Your Heavy-Duty Conveyor Specification Checklist

We know getting these details right can feel like a lot, but our team is here to take the guesswork out of it. We offer free layouts and designs where our experts crunch these complex numbers for you. This collaborative approach makes sure your system is perfectly engineered for your operation from day one. Bringing in an expert early in the planning process is the best way to prevent expensive mistakes and get your project on a faster track to installation.

Here is a quick checklist to walk you through the spec process:

- Maximum Unit Load: What are the weight and dimensions (length, width, height) of your single heaviest item?

- Load Capacity Per Foot: What is the total weight capacity needed for any given section of the conveyor line?

- Roller Specifications: Based on your load and environment, what roller diameter and material (like galvanized steel) do you need?

- Roller Spacing: What is the right distance between roller centers to ensure your smallest load is always on at least three rollers?

- Between Frame (BF) Width: How wide is your widest product? Add 2-4 inches total for clearance to find your BF width.

- Frame Gauge: Will a heavy steel like 10-gauge be enough to support your max load without flexing?

- Support Legs: What height do you need, and do the support legs have a capacity rating that exceeds the conveyor's load?

Our experts can guide you through every one of these points to make sure nothing gets missed. For an even deeper dive, you can check out our detailed conveyor specification guides. Ready to get started? Request a Quote or give our team a call at Call (800) 326-4403 for a no-obligation consultation.

Real World Applications and Industry Use Cases

Specs and theory are one thing, but seeing a heavy-duty roller conveyor in action is where its value really clicks. These systems are the unsung heroes of countless industries, handling jobs that would otherwise be slow, back-breaking, and downright dangerous. Once you see them at work, you start to spot opportunities in your own facility.

Let us take a look at how different sectors are putting these workhorses to use, solving tough material handling problems and making their operations run smoother.

Warehousing and Distribution Centers

In the world of logistics, speed is everything. Warehouses and distribution centers depend on heavy-duty roller conveyors to keep pallets, totes, and oversized cartons moving without a hitch. A smart conveyor layout dramatically cuts down on forklift traffic—a major source of congestion and workplace accidents.

A classic example is using a Chain Driven Live Roller (CDLR) conveyor to move pallets. A CDLR system has the muscle to reliably move fully loaded pallets weighing thousands of pounds from the receiving dock to staging areas or right into your pallet racking. It creates a steady, predictable flow that improves both throughput and safety.

By getting forklifts out of the long-haul pallet moving game, facilities create a much safer floor and free up skilled operators for more complex jobs like loading trucks or high-level putaway. It is a simple change that delivers huge productivity gains.

Manufacturing and Assembly Lines

Manufacturing plants are tough on equipment. Heavy-duty roller conveyors are built for these environments, designed to handle the grind of moving raw materials, work-in-progress, and finished goods day in and day out. Think engine blocks, steel coils, heavy castings—this is the stuff they were made for.

Here is where you will commonly see them in a manufacturing setting:

- Assembly Lines: Shuttling heavy subassemblies from one station to the next, letting workers focus on their specific tasks instead of wrestling with heavy parts.

- End-of-Line Packaging: Moving finished products like large appliances or crated machinery over to the palletizing and shrink-wrapping stations.

- Raw Material Infeed: Feeding heavy stock like steel drums, castings, or metal sheets directly into production machinery.

The sheer durability of a CDLR system, for instance, makes it perfect for handling oily or abrasive parts that would destroy lighter-duty conveyor types.

Specialized Industry Applications

The versatility of the heavy duty roller conveyor design means it shows up in some highly specialized fields with very specific demands. These industries often need custom-tailored solutions to meet tough regulatory or environmental challenges.

Food and Beverage: In any facility where sanitation is king, stainless steel conveyors with washdown-ready motors are non-negotiable. These systems are engineered to survive daily high-pressure washdowns with caustic chemicals, which is critical for preventing contamination and meeting food safety standards. They are used to move everything from heavy crates of produce to massive vats or bulk bags of ingredients.

Automotive: The auto industry relies on heavy-duty conveyors to move vehicle chassis, engine assemblies, and pallets of components down the assembly line. The precision and absolute reliability of these systems are essential for keeping up with the brutal production schedules of modern car manufacturing.

The common thread here is the need for powerful, reliable, and safe material transport. Planning a system that ticks all those boxes for your specific operation can feel overwhelming, but it does not have to be. Getting a professional layout done early in the process is the best way to avoid costly mistakes and ensure a smooth installation.

Ready to see how a heavy-duty system could fit into your workflow? Contact Us for a free, no-obligation design and quote, or call our experts directly at Call (800) 326-4403.

Weaving Conveyors into Your Existing Workflow

Dropping a new conveyor system into your facility should make life simpler, not harder. The real magic of a heavy-duty roller conveyor happens when it integrates seamlessly with your existing equipment, becoming the central artery of your operation instead of just another standalone machine.

Proper integration is what turns a bunch of separate processes into a smooth, cohesive material flow from one end of your building to the other. It is about getting products to glide from receiving docks, onto conveyor lines, through sortation, and up to mezzanines or pallet racking without a single hitch or bottleneck.

Connecting Conveyors with Your Warehouse Infrastructure

It all starts with the physical layout. A smart design ensures your conveyor lines up perfectly with key parts of your warehouse, creating a fluid path for every item.

Think about these key connection points:

- Pallet Racking: Conveyors can feed heavy loads directly into pallet racking systems, staging them perfectly for forklift putaway. This simple move slashes forklift travel time and clears up congestion in busy aisles.

- Mezzanines: Why dedicate precious floor space to lifts or elevators? Integrating conveyors with mezzanines lets you move products between levels effortlessly, effectively doubling your usable footprint.

- Sortation Systems: Powered roller conveyors are the lifeblood of high-speed sortation. They guarantee a steady, properly spaced flow of packages or totes, which is crucial for accurate diverting.

A well-thought-out layout prevents the kind of expensive workflow headaches that come from poor planning. Taking the time to map out these connections from the very beginning is absolutely critical.

The Brains of the Operation: Automation and Controls

In today's automated facilities, integration is about more than just physical placement. Powered roller conveyors have to communicate with your other automated systems to create a truly intelligent workflow. This is where sensors and programmable logic controllers (PLCs) come in.

Expert Insight: Think of the PLC as the "brain" of the automated line. It takes information from sensors to control conveyor speed, manage zones, and interact with other machines. It is what allows a conveyor to "talk" to a robot.

For instance, sensors can detect when a tote reaches the end of a line and signal an Automated Guided Vehicle (AGV) to come pick it up. In the same way, a robotic palletizer can tell a zero-pressure accumulation conveyor to send the next carton, creating a perfectly synchronized process.

Planning Ahead for Future Growth

Putting in a heavy-duty roller conveyor is not just about fixing today's problems; it is about setting yourself up for tomorrow's growth. The choices you make in the planning phase will directly impact your ability to scale down the road.

We have found that starting the design conversation early helps businesses lock in better project timelines and sidestep the delays that can derail seasonal prep or expansion plans. Our design services help you think ahead, creating a layout that not only works now but can be easily expanded as your business grows. By considering future automation and throughput needs today, you build a system that will not require a costly overhaul in a few years. Learn more about our approach to comprehensive full warehouse design solutions.

Ready to build a seamless workflow? Request a Quote or give our design experts a call at Call (800) 326-4403 to start planning your integration.

Conclusion: Let's Get Your Project Rolling

We have covered a lot of ground in this guide, from the nuts and bolts of selecting a heavy duty roller conveyor system to getting the specs just right for a serious return on your investment. Now, it is time to put all that theory into practice. Think of us as your expert partner in this process—we are here to deliver not just hardware, but a real solution, backed by competitive pricing and some of the fastest shipping in the industry.

One of the biggest values we bring to the table is our free design service. Instead of guessing, you can lean on our team's experience to make sure your system is engineered for peak performance from the get-go. Don't let operational bottlenecks dictate how much your facility can grow.

Getting the conversation started with our team today is the best way to get ahead of planning. It helps you dodge the kind of delays that can derail an expansion or leave you scrambling before your busy season. Getting an expert eye on your plans is the key to building a material handling workflow that is not just efficient, but truly scalable. Let us help you design the perfect setup that fits your unique needs and, just as importantly, your budget.

Ready to Upgrade Your Material Handling?

Don't let an inefficient product flow hold you back any longer. Our experts are ready to provide a free, no-obligation layout and quote tailored specifically to your facility's unique challenges and goals. With our competitive pricing and industry-leading shipping speeds, you can get your operations optimized much sooner than you think.

Request a Free Quote

Frequently Asked Questions

When you are looking to invest in equipment as critical as a heavy-duty roller conveyor, you are bound to have some questions. It is only natural. Getting straight, clear answers is the best way to make sure you get the right system for your facility's unique challenges. Here are a few of the most common questions we get from managers and buyers on the front lines.

What Is the Typical Lifespan of a Heavy Duty Roller Conveyor?

With a consistent maintenance routine, a high-quality heavy duty roller conveyor system is built to last. Many facilities see 20 years or more of reliable service from their initial investment. The actual lifespan really comes down to a few key factors: the harshness of the operating environment, the average load weight, and just how many hours it runs per day.

Think of it like a fleet vehicle. Components that see the most action, like bearings and drive chains on powered models, are designed to be easily swapped out. This modular approach lets you extend the life of the entire system significantly, making it a durable, long-term asset instead of a short-term fix.

Can Heavy Duty Roller Conveyors Be Customized?

Absolutely. In fact, customization is one of the biggest reasons people choose these systems. It is rare that a standard, off-the-shelf conveyor fits a specific workflow perfectly. That is why we engineer a heavy duty roller conveyor solution that is tailored precisely to your operation.

You can specify nearly every part of the design:

- Between-Frame Width: To perfectly match your product dimensions.

- Roller Spacing and Diameter: To guarantee proper load support without sagging.

- Overall Length and Height: To fit your building's layout and ergonomics.

- Roller Material: Such as galvanized or stainless steel for washdown or corrosive environments.

For powered systems, customization can also include variable speed controls and seamless integration with other automated equipment. Our team specializes in providing free, custom layouts to make sure the final product is a perfect operational match from day one.

How Do I Determine the Right Load Capacity?

Getting the load capacity right is non-negotiable for both safety and performance. The most important rule to remember is to base your calculations on the weight of the single heaviest item you will ever move, not just an average. The system's capacity is usually rated "per foot," and you also have to make sure the load is supported by at least three rollers at all times to prevent it from tipping or damaging the conveyor.

It is always a smart move to build in a safety margin to handle those unexpected heavy loads. Our experts can run these calculations for you during a free design consultation, guaranteeing your system is specified for maximum safety and long-term durability.

Is Professional Installation Necessary?

Whether you need a pro installer really depends on how complex the system is. Long, straight sections of a gravity roller conveyor are pretty simple to assemble and can often be handled by a skilled in-house maintenance team.

However, for powered systems—especially those with tricky controls, curves, or integration with other automation—we strongly recommend professional installation. This ensures everything is set up correctly, safely, and is optimized for your workflow right from the start. When you Contact Us, we can walk you through the best installation approach for your specific system.

At Material Handling USA, our entire focus is on providing a solution that fits your operation like a glove. We offer free, no-obligation layouts and quotes to help you design a system that boosts efficiency and safety. Let us explore your options today.

https://www.mh-usa.com