Stretch wrapping a pallet is the process of using a highly stretchable plastic film to unitize a load for shipping or storage. When done correctly, it creates a solid, stable unit that is secure from shifting, dirt, and moisture. This is a non-negotiable step in the supply chain because it directly protects your products, boosts shipping efficiency, and helps control costs.

Why Flawless Pallet Wrapping Is Your First Line of Defense

Let's be honest, stretch wrapping can feel like just another task to check off the list. But for warehouse managers and logistics coordinators, getting it right is one of the most critical—and often overlooked—parts of a successful supply chain. A perfectly wrapped pallet is your first line of defense against the chaos of transit.

The fallout from poor load containment is significant, going well beyond the cost of one damaged item. It kicks off a ripple effect: expensive returns, hours of administrative time wasted on claims, and the hit your reputation takes from a failed shipment. A perfectly wrapped pallet isn't just about stability; it's a direct reflection of your operational standards and a key driver of your bottom line.

The True Cost of Inadequate Wrapping

When a load fails, the immediate loss is obvious. But it's the hidden costs that can impact profitability:

- Labor Inefficiency: Time spent re-wrapping unstable pallets or cleaning up spills is time taken from more productive work.

- Customer Dissatisfaction: Damaged shipments can erode trust and put future business at risk.

- Increased Freight Claims: Filing and managing claims is a resource-heavy process that impacts your profitability.

Beyond just protecting your products, proper pallet wrapping is a massive contributor to workplace safety, which is a key part of any conversation on essential safety topics for work. An unstable load is a serious hazard, putting employees at risk of injury during handling and transport.

The Growing Importance of Automation

The push for better efficiency and security is fueling investments in wrapping technology. The global stretch wrapper market is expected to grow significantly, signaling intense demand for reliable load containment.

Modern automated wrappers can slash film usage by up to 50% and cut damage claims by 25%, showing a fast and clear return on investment. This isn't just an operational upgrade; it's a strategic move to protect your assets, from the warehouse floor all the way to your customer's door. Giving your team the right tools and knowledge is the foundation of a resilient supply chain.

Choosing Your Tool: Hand Wrapping vs. Machine Wrapping

Sooner or later, every operation faces this question: should we continue wrapping pallets by hand, or is it time to invest in a machine? This isn't just about speed; it's a major operational decision that hinges on your volume, consistency, labor costs, and safety standards. Let's break down how to make the right call for your facility.

Hand wrapping is where most businesses start. It's straightforward, requiring only a roll of film and a dispenser. This manual approach gives you incredible flexibility, which is perfect for low-throughput operations or for awkward, non-standard pallet loads.

But as your business grows, the hidden costs of manual wrapping start to add up. What once seemed like a low-cost solution can quickly become a bottleneck.

When Hand Wrapping Still Makes Sense

Manual stretch wrapping has its place. If your team ships fewer than 10-15 pallets per day, the labor cost and time spent are usually manageable. It's also the go-to solution for one-off, oddly shaped items where a machine’s uniform process just won't cut it.

Hand wrapping is the right tool for the job in these situations:

- Low Volume Operations: Startups and smaller businesses without the consistent, high-volume shipping to justify a machine.

- Irregular Loads: Wrapping custom machinery, furniture, or mixed-product pallets that have no uniform shape.

- Tight Budgets: When capital for new equipment is limited and your current output doesn’t justify the expense.

The Tipping Point for Automation

The conversation changes entirely when you start prioritizing consistency and looking after your employees. Are you seeing inconsistent wrap quality between shifts? Are workers complaining about dizziness, fatigue, or back strain from circling pallets all day? Those are flashing signs that it's time to look at automation.

A machine applies the exact same tension and number of wraps every single time. It creates a reliable, repeatable standard that is almost impossible for a human to match, load after load.

This is where investing in a machine becomes a smart financial move. Automation can slash labor costs and cut film waste by over 50%, thanks to advanced pre-stretch capabilities you just don't get with hand film.

To help you decide, here’s a quick look at the core factors that separate the two methods. This isn't just a simple pros and cons list; it's a decision matrix to align your operational reality with the right wrapping strategy.

Decision Matrix: Hand Wrap vs. Machine Wrap

| Factor | Hand Stretch Wrapping | Machine Stretch Wrapping |

|---|---|---|

| Volume | Ideal for under 15 pallets/day. | Essential for 15+ pallets/day. Scales easily with growth. |

| Consistency | Highly variable. Depends on the operator, fatigue, and technique. | 100% consistent. Same tension and wraps every time. |

| Film Costs | Higher per-pallet cost. No pre-stretch means you use more film. | 50%+ film savings. Pre-stretch technology gets more out of every roll. |

| Labor Costs | High. Labor-intensive process that takes employees from other tasks. | Low. Frees up employees to focus on more productive work. |

| Safety | High risk of back strain, repetitive motion injuries, and dizziness. | Minimal risk. The operator simply attaches the film and presses start. |

| Load Security | Inconsistent. Prone to product damage from loose or uneven wraps. | Superior. Engineered wrap containment secures loads effectively. |

After reviewing the table, it becomes clear that while hand wrapping is a necessary starting point, scaling operations demand the efficiency, safety, and cost savings that only a machine can provide.

Key Takeaway: Upgrading to a machine isn't just about moving pallets faster. It's about engineering a consistent, secure wrap that drastically reduces the risk of product damage during transit, which in turn slashes return rates and protects your bottom line.

There’s a whole world of machines out there, from semi-automatic turntable wrappers for standard operations to rotary arm models for high-speed lines or unstable loads. The best way to know if it's time to upgrade is to look at the numbers. Your daily pallet count, labor costs, and product damage rates will tell you exactly where the breakeven point is. For most businesses shipping more than 15 pallets a day, the efficiency gains and material savings make a compelling case for the investment.

Explore our complete lineup of stretch wrap machines for pallets to see which model fits your operation, or Request a Quote for personalized guidance from our team.

Decoding Stretch Film for Maximum Load Security

Not all stretch film is created equal. Many companies invest heavily in products, only to lose money from damaged shipments because they used the wrong wrap. Choosing the right material is every bit as important as your wrapping technique, and it’s a decision that impacts both load security and your bottom line.

Let's break down how to choose the right film so you can make confident, cost-effective decisions for your warehouse. This is about looking past the price per roll to see the real cost of containment.

The global market for stretch wrap materials continues to grow because in today's demanding logistics world, smarter load containment isn't a luxury; it's essential. Picking the right film is a strategic move that directly prevents transit damage and cuts down on material waste.

Cast Film vs. Blown Film: What Matters for Your Load

The two main players in the stretch film game are cast and blown. They're made differently, and that difference impacts everything from puncture resistance and load retention to how loud it is on your warehouse floor.

- Cast Stretch Film: This is the go-to for most operations. It's known for its crystal-clear clarity, it unwinds quietly, and it has a reliable two-sided cling. If you're wrapping uniform loads like stacked boxes and need to scan barcodes through the film, cast is your workhorse.

- Blown Stretch Film: Think of this as the heavy-duty option. Blown film has superior puncture and tear resistance, which makes it perfect for those tricky, irregular loads with sharp corners or heavy contents that like to shift. It's usually a bit hazier and makes more noise coming off the roll, but that extra strength provides a serious upgrade in load security.

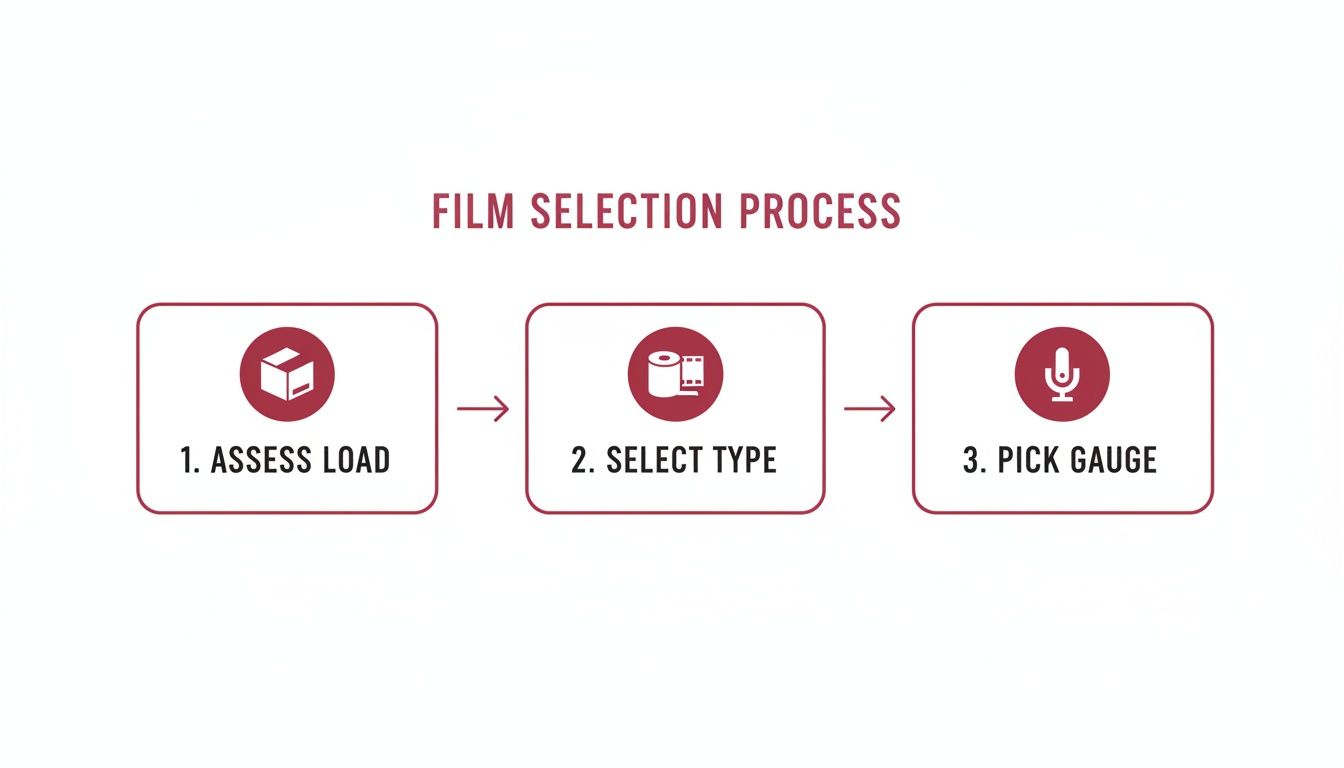

A Practical Guide to Selecting the Right Gauge

The "gauge" is simply a term for the film's thickness, measured in mils. Using a film that’s too light can lead to load failure, but going too heavy is like throwing money away. The right gauge comes down to the weight and shape of your pallet.

Here’s a simple cheat sheet:

| Load Weight & Type | Recommended Film Gauge | Ideal For |

|---|---|---|

| Up to 1,500 lbs (Light, uniform boxes) | 60 – 70 Gauge | Stable, lightweight products with no sharp edges. |

| 1,500 – 2,200 lbs (Medium, mixed loads) | 80 Gauge | The most common, all-purpose gauge for a huge variety of pallets. |

| 2,200 – 3,000 lbs (Heavy, irregular loads) | 90 – 120 Gauge | Heavy items, machinery parts, or loads with sharp corners. |

The Power of Pre-Stretch Technology

This is where the real efficiency gains happen. Modern, high-performance films are engineered with pre-stretch capabilities, which let you "down-gauge"—that is, use a thinner film without losing any strength. Machine wrappers actually stretch the film before it's applied to the pallet, which multiplies its yield and boosts its tensile strength.

This technology is a game-changer. A high-quality 63-gauge pre-stretch film can provide the same—or better—load containment as a standard 80-gauge film. That's an instant reduction in material consumption and cost per pallet wrapped.

At the end of the day, the goal is to find the most efficient and effective film for your specific loads. Our team can help you analyze what you’re wrapping and how you’re wrapping it to find those opportunities for improvement.

For a look at our full range of films and other warehouse staples, check out our collection of frequently purchased shipping and packing supplies.

The Art of the Perfect Wrap From Start to Finish

Knowing which film and wrapping method to use sets the stage, but flawless execution is what guarantees your products arrive safely. Nailing a secure, shipment-ready pallet is a repeatable process. It boils down to three critical phases: preparing the load, applying the wrap, and securing the tail.

Proper technique starts long before the first inch of film touches the pallet. A great wrap can't fix a bad stack. The goal is to build a solid, column-stacked or interlocked unit that moves as a single block, minimizing any chance of products shifting around during transit.

Preparing the Load for Containment

The foundation of a perfect wrap is a well-built pallet. This is half the battle. Start by ensuring your boxes or items are stacked as squarely as possible, keeping everything within the pallet's edges. Any products hanging over the side are at high risk of damage from forklifts, racking, and other pallets.

Whenever possible, use an interlocking brick pattern. This stacking technique dramatically improves load stability and cuts down the risk of boxes shifting or toppling over. Think of it like building a strong wall where each layer supports the ones around it, creating a unified and much more secure structure from the inside out.

Once your load is prepped, you can confidently choose your film. The right choice depends entirely on the load you just built.

This just reinforces the point: a successful wrap starts with understanding your load's specific needs before you even pick up a roll of film.

Applying the Film for Maximum Strength

With a correctly stacked pallet, you're ready to wrap. The objective here is simple but absolutely crucial: bond the load to the pallet itself. The pallet and the product must become one solid, inseparable unit.

First, anchor the film securely to a corner of the pallet base. You can tie it on or just tuck a short tail under the first layer of boxes. With the film anchored, apply three to five wraps around the pallet base. Make sure the film catches both the bottom of the load and the pallet. This step is non-negotiable—it creates the strong foundation that locks everything together.

As you start moving up the load, maintain a consistent 50% overlap with each revolution. This simple technique ensures there are always at least two layers of film covering every part of your product, creating a strong, cohesive sheet that distributes tension evenly. Proper overlap is the key to preventing tears and maintaining that all-important containment force.

A common mistake is wrapping the load but not the pallet. True load security happens only when the film creates a unified bond between the products and the pallet they're sitting on. If they aren't wrapped together, the load can still slide right off the pallet base during shipment.

Wrap all the way to the top, overlapping the top edge by a few inches to add extra stability. Then, work your way back down the pallet, again maintaining that 50% overlap, until you reach the bottom where you started.

Finishing the Wrap Securely

How you finish is just as important as how you start. A loose film tail can easily get snagged on machinery or another pallet, causing the entire wrap to unravel in transit. It’s a common and completely avoidable point of failure.

To finish strong, cut the film from the roll, leaving a tail about two feet long. Tightly twist this tail into a "rope" and tuck it firmly underneath one of the outer wrap layers. This creates a secure end that won't come loose.

Following these steps for every pallet builds a repeatable, reliable technique. Companies that rigorously test their wrapping methods often discover that precise adjustments to overlap and tension—even with thinner gauge films—can maintain perfect load integrity while saving significantly on material costs.

If your team is struggling with consistency, it might be time to discuss a more automated solution. Request a Quote for a free consultation on how a stretch wrapper can standardize your process and bulletproof your load security.

Common Pallet Wrapping Mistakes and How to Fix Them

Even the most experienced warehouse crews run into stretch wrapping problems. A small mistake in technique or a slightly off machine setting can snowball into major headaches down the road. This is your go-to troubleshooting guide for turning those wrapping fails into a stronger, more secure pallet load.

When a wrapped pallet fails, it’s usually not a big mystery if you know what signs to look for. The first step is always figuring out what went wrong. Once you identify the root cause, the fix is often surprisingly simple and keeps the same issue from happening again.

Why Does My Film Keep Breaking?

Constant film breaks are more than just frustrating—they bring your entire operation to a standstill. When your stretch film keeps snapping mid-wrap, it almost always comes down to an issue with the film itself or how you're applying it.

More often than not, the culprit is simply too much tension. Whether you're pulling too hard on a manual dispenser or the machine settings are dialed up too high, you're stretching the film past its limits. Another common reason is the film catching on sharp corners of boxes or the pallet itself, which can easily cause a puncture that turns into a full-blown tear under pressure.

Pro Tip: Before you blame the stretch film, do a quick check. Run your hand carefully along the pallet's edges and the corners of the boxes. A jagged piece of wood on the pallet or a sharp cardboard corner is often the real troublemaker. Sanding down a splinter or adding a corner board can solve your film break problems in seconds.

A less obvious cause? You might be using the wrong tool for the job. A lightweight, 60-gauge film just doesn't have the strength to hold together a heavy or unstable load. It's bound to give out under that kind of strain.

Troubleshooting Common Wrapping Failures

Once you’ve got a good idea of the cause, the solution is usually straightforward. The key is to fix the underlying issue instead of just patching up the symptom.

We've put together this quick-reference table to help you identify and solve the most frequent problems we see in the field.

| Problem | Likely Cause | Solution |

|---|---|---|

| Film Breaks Mid-Wrap | Tension is set too high, or the load has sharp corners. | Dial back the tension on your wrapper. Apply cardboard edge protectors to shield the film from getting snagged on sharp edges. |

| Load Shifts Inside Wrap | Not enough containment force, or the load isn't properly locked to the pallet. | Increase your wrap tension slightly. Make sure the first 3-5 wraps are low and tight, securing the bottom layer of boxes directly to the pallet. This is critical. |

| Film Tail Comes Undone | The end of the film wasn't secured properly after the wrap was finished. | Take the last two feet of film, twist it into a tight "rope," and tuck it firmly underneath one of the outer layers of wrap. This holds much better than just pressing it flat. |

| "Tenting" at Corners | The film is bridging across the corners instead of hugging the load tightly. | Increase the film tension just enough to pull the film flush against the load's shape. You want to eliminate any gaps and ensure complete contact. |

Think of every imperfect wrap as a learning opportunity. Use these common issues as a mental checklist to audit your wrapping process. If you notice the same problems happening over and over, it’s a strong signal that you might need better training or an equipment upgrade. When your team is constantly fighting film breaks and shifting loads, it's a sure sign your current methods can't keep up anymore.

Our specialists are seeing more managers looking for ways to standardize their wrapping to avoid these exact issues. A little planning now can prevent a lot of costly disruptions later. Contact Us or give us a call at (800) 326-4403 for a no-pressure chat about how the right equipment can make these common failures a thing of the past.

Building a Complete Pallet Security System

A great wrap is the core of load security, but it’s not the whole story. The final step is to build a complete palletizing solution that protects your products from every angle. By introducing a few complementary products, you can turn a well-wrapped pallet into a truly bulletproof shipping unit.

This final layer of protection addresses specific threats that stretch wrap alone might not solve. For instance, pallet covers are an inexpensive way to shield your products from dust, dirt, and moisture during storage or transit. Strapping adds another level of containment for unusually heavy or unstable loads.

Reinforcing Your Load for Transit

Thinking beyond just the film allows you to build a system that anticipates and solves potential problems before they happen. This proactive approach is what separates good shipping operations from great ones.

Consider these strategic additions:

- Pallet Covers: These simple plastic sheets provide top-layer protection against environmental factors. They are essential for any products sensitive to moisture or that will be stored for extended periods.

- Steel or Poly Strapping: For exceptionally heavy loads like machinery parts or building materials, strapping provides rigid containment that stretch film can't match. It prevents loads from shifting or separating under extreme force.

- Edge Protectors: These are one of the most effective and underutilized tools. Made of rigid cardboard, they accomplish two critical goals: they protect your products from strapping and film tension, and they add significant vertical stacking strength to the entire pallet.

By combining a solid wrap with tools like cardboard edge protectors for shipping protection, you create a unified structure. This system distributes pressure evenly and reinforces weak points, drastically reducing the chances of a load failure.

Knowing When to Add More Protection

The key is identifying which additions offer the best return for your specific loads. You don't need to apply every solution to every pallet, but knowing when each one is vital is crucial for efficiency.

For example, if you're shipping uniform, lightweight boxes to a clean distribution center, a good quality stretch wrap is likely sufficient. However, if that same load is going to a construction site where it might sit outside, adding a pallet cover becomes a necessity. A heavy, irregular load of metal parts absolutely requires strapping and edge protectors to prevent shifting and product damage.

Building a comprehensive pallet security strategy is a forward-thinking move that pays off in reduced damage claims, fewer shipping delays, and higher customer satisfaction. Investing time now to plan your entire approach is a strategic decision that optimizes your shipping operations for the long term. These decisions are becoming more common as managers look to avoid future supply chain disruptions by strengthening their processes today.

At Material Handling USA, we provide all the components you need to build a complete pallet security system. Our team offers free layout and design consultations to help you create the most efficient and cost-effective solution for your facility. Request a Quote or call (800) 326-4403 to speak with a specialist.