Choosing the right warehouse material handling equipment is like picking the perfect players for a championship team. It's the backbone of your supply chain, influencing every touchpoint of your products—from moving and storing to protecting and controlling everything that comes through your doors. The systems you put in place directly shape your daily productivity, operating budget, and team safety.

Ultimately, getting your equipment mix right determines whether you can consistently meet customer demands or fall behind the competition.

Getting a Handle on Your Equipment Options

Think of a well-equipped warehouse as a strategic asset, not just a cost center. When you get the equipment right, you transform your supply chain into a powerful competitive advantage. The entire goal is to create a seamless, safe, and efficient flow of products from receiving to shipping, and that simply isn't possible without the right tools for the job.

Investing in the proper systems isn't just about moving boxes from Point A to Point B a little faster. It's about building a cohesive ecosystem that slashes wasted motion, prevents product damage, and boosts your overall output. This guide will break down the essential equipment categories, helping you make smarter, more informed decisions for your facility. We'll show you how the right combination of tools can bust through common bottlenecks and get your operation ready for whatever comes next.

Why Is Nailing Your Equipment Selection So Critical?

Picking the right material handling solutions has a direct, measurable impact on your bottom line. It's not just a "nice to have." A strategic approach to outfitting your facility helps you:

- Boost Productivity: The right systems cut down the time it takes to receive, put away, and ship goods. This lets your team process more orders with less effort.

- Keep Your People Safer: Good equipment drastically reduces the need for manual lifting of heavy or awkward loads, a leading cause of workplace injuries. This protects your team and cuts the risk of expensive downtime.

- Get More Out of Your Space: Smart storage solutions like pallet racking and mezzanines let you tap into your warehouse's vertical cube. You can often double or even triple your storage capacity without a costly expansion.

- Lower Operational Costs: When you improve efficiency and reduce product damage, the right equipment delivers a powerful return on your investment, plain and simple.

A well-planned material handling system does so much more than just move products. It optimizes your entire operational flow, turning potential headaches into opportunities for greater efficiency and profit.

Partnering for Success From Day One

Trying to navigate the massive world of warehouse equipment on your own can be overwhelming. That’s why we don't just sell products; we deliver complete, thought-out solutions. Our entire process starts with a simple conversation to understand what makes your operation tick. We genuinely believe that a successful layout is the foundation of any high-performing warehouse.

At Material Handling USA, we provide free layouts and designs with no obligation to help you see exactly how the optimal equipment configuration will work in your space. This collaborative, see-it-before-you-buy-it approach guarantees that your investment is perfectly dialed in to your business goals from the get-go.

Ready to see what's possible for your facility? Contact Us today for a free consultation and discover how the right equipment can completely transform your operations.

Getting to Know the Core Categories of Material Handling Equipment

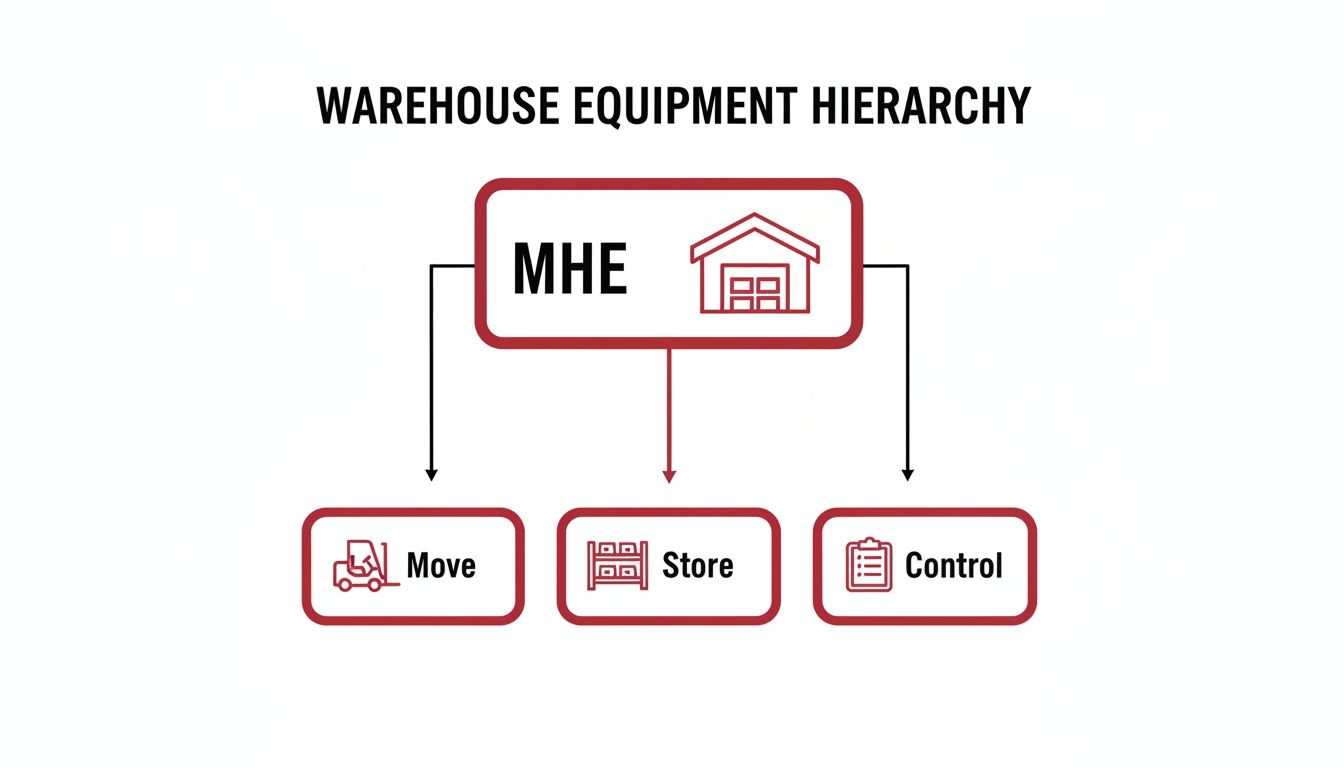

Stepping into the world of warehouse equipment can feel overwhelming at first, but it gets much simpler when you break it down. To achieve an efficient flow of goods, you have to understand that everything falls into a few key categories. Think of it less as a random collection of tools and more as a coordinated system with distinct functions.

This diagram gives you a bird's-eye view of how all the pieces fit together—everything from moving and storing to controlling materials is part of the bigger Material Handling Equipment (MHE) puzzle.

What this really shows is that a great warehouse strategy is a balanced system. It is never just about one piece of equipment working in isolation; it’s about how they all work together.

To help you get a handle on what's what, we've put together a quick reference table. It breaks down the main equipment types, what they do, and where they shine.

Material Handling Equipment Categories and Applications

| Equipment Category | Primary Function | Common Examples | Best For… |

|---|---|---|---|

| Storage & Handling | Maximize space and securely store inventory. | Pallet Racking, Shelving, Mezzanines | High-density storage, organizing SKUs, and leveraging vertical space. |

| Bulk Handling | Move large quantities of loose materials. | Conveyor Systems, Stackers, Elevators | Continuous flow operations for items like powders, liquids, or small parts. |

| Industrial Trucks | Transport goods over short distances within the facility. | Forklifts, Pallet Jacks, Order Pickers | Loading/unloading, moving pallets, and order fulfillment tasks. |

| Engineered Systems | Integrate multiple components for automated workflow. | Automated Storage & Retrieval Systems (AS/RS) | High-throughput, data-driven operations needing maximum accuracy and speed. |

This table gives you a quick snapshot, but let's dive into what each category really means for your day-to-day operations.

Storage and Handling Equipment

This category is the absolute foundation of any organized warehouse. Storage and handling equipment is all about making the most of your facility's footprint—keeping your inventory safe, secure, and easy to access. The name of the game is using every inch of your space, especially vertical space, as efficiently as you can.

You'll see this in action with common examples like:

- Pallet Racking: These are the steel skeletons of most warehouses, built specifically to hold palletized inventory.

- Industrial Shelving: Perfect for all the smaller stuff—non-palletized items, bins, cartons, you name it.

- Mezzanines: These are elevated platforms that literally create a second floor inside your warehouse, perfect for adding storage or even office space.

For those looking to get even more efficient, specialized options like this Gravity Flow Racks Guide show how smart design can maximize density and product rotation.

Bulk Material Handling

When you are dealing with huge volumes of loose materials—think liquids, powders, or tiny components—bulk material handling equipment is your go-to. These systems are designed for a continuous, automated flow. They are the arteries of a high-volume facility, keeping production and fulfillment lines humming without any manual bottlenecks.

The most recognizable piece of gear here is the conveyor system. We've got a detailed guide that explains how different types of conveyors move materials and boost productivity. Other examples include things like stackers, reclaimers, and elevators, all built for specific types of bulk goods.

Industrial Trucks

Industrial trucks are the true workhorses of the warehouse. They provide the muscle for transporting goods over short distances, doing all the heavy lifting that would be impossible or unsafe for a person to handle. Think loading, unloading, and moving heavy pallets from point A to point B.

This category is pretty broad, but it includes the essentials:

- Forklifts: The undisputed icon of warehouse work, used for lifting and moving pallets.

- Pallet Jacks: Also called pallet trucks, these are for moving pallets around at ground level.

- Order Pickers: These machines lift an operator up to high shelves to grab individual items for an order.

Engineered Systems

Engineered systems are where it all comes together. This is about integrating various pieces of equipment to create a single, cohesive, and often automated, workflow. These systems lean on technology to control and move goods with minimal human input, which dramatically increases both accuracy and throughput. This is the hallmark of a modern, data-driven operation.

How To Select The Right Equipment For Your Warehouse

Choosing the right warehouse material handling equipment is one of the most impactful decisions you'll make for your operation. This isn't just a purchase; it's a long-term investment in your facility's efficiency, safety, and bottom line. Getting it right from the start prevents costly mistakes down the road and ensures your capital delivers a real, measurable return.

Think of this section as a practical framework for your decision-making. It’s a strategic checklist to help you confidently select equipment that lines up perfectly with your operational goals. A thoughtful approach now means avoiding expensive fixes and workflow headaches later.

Start With A Thorough Needs Analysis

Before you even glance at a single spec sheet, you have to understand the problem you're trying to solve. A comprehensive needs analysis is the bedrock of any smart equipment purchase. This means mapping out your current workflows, pinpointing the bottlenecks, and getting crystal clear on your objectives.

Start by asking the hard questions:

- What specific tasks desperately need improvement (e.g., faster picking, denser storage, safer transport)?

- Where are the most painful delays or inefficiencies in our current process?

- What do our growth projections look like for the next 3 to 5 years?

Answering these honestly gives you a clear roadmap. It stops you from buying a piece of equipment that only puts a bandage on a symptom instead of fixing the root cause.

Evaluate Your Product Characteristics

The physical nature of your products will dictate many of your equipment choices. You simply can't select the right tools without first understanding the materials they’ll be handling day in and day out. A system designed for small, lightweight cartons will fail spectacularly if you suddenly ask it to handle heavy, oversized pallets.

Drill down into these key product attributes:

- Size and Shape: Are you dealing with uniform boxes, oddly shaped items, or long materials like pipes and lumber?

- Weight: What is the average and, more importantly, the maximum weight of the items being moved or stored? Forklift and racking capacities are non-negotiable.

- Fragility: Do your products require a delicate touch to prevent damage? This influences everything from conveyor speed to the type of forklift attachments you'll need.

Analyze Your Facility's Layout And Constraints

Your building itself is a critical piece of the puzzle. The physical limitations and features of your warehouse will either enable or restrict certain types of equipment. Aisle width, ceiling height, and floor quality aren't just details—they are hard constraints you have to work within.

Key facility considerations include:

- Aisle Width: This is the deciding factor between standard forklifts and specialized narrow-aisle or very-narrow-aisle trucks.

- Ceiling Height: High ceilings are a golden opportunity for vertical storage with tall racking systems, but only if you have the right lift equipment to reach the top.

- Floor Condition: Can your concrete slab support the immense point loads from fully loaded racks and heavy machinery? Cracks and uneven surfaces can be a deal-breaker.

- Throughput Requirements: How many items, pallets, or orders do you need to push through per hour or per shift? Your equipment has to be able to keep up with your operational velocity.

Get Your Free Layout and Design Consultation

Unsure how to best utilize your space? Our experts provide free, no-obligation layout and design services to help you visualize the optimal equipment configuration for your facility. Contact Us to get started!

Prioritize Ergonomics And Safety

Finally, never, ever overlook the human element. The well-being of your team is paramount, and good ergonomic design is directly tied to productivity and safety. Equipment that reduces physical strain, repetitive motion, and awkward postures is proven to prevent injuries. According to OSHA, focusing on ergonomics can dramatically lower injury rates and boost employee morale.

Investing in ergonomically sound warehouse material handling equipment isn't an expense; it’s a strategy for building a more efficient, reliable, and happier workforce.

By systematically working through this checklist, you can move forward confidently, ready to invest in equipment that drives real, tangible improvements. Ready to talk specifics? Request a Quote today.

The Growing Impact of Automation In Material Handling

If you think warehouse automation is just for corporate giants, it’s time to think again. It is no longer a far-off concept; it’s a practical, strategic tool that gives operations of any size a serious competitive edge. Embracing automation is really about future-proofing your facility against the realities of labor shortages, rising costs, and customers who want everything faster and more accurately.

The goal isn't just to replace manual labor. Instead, automated warehouse material handling equipment builds a smarter, more reliable, and data-rich ecosystem. This frees up your skilled team members from repetitive, physically draining tasks so they can focus on higher-value work like quality control, process improvement, and handling exceptions. It’s a shift that doesn’t just boost the numbers—it improves workplace safety and employee morale, too.

Key Players in Warehouse Automation

Diving into automation means getting to know a few key technologies. Each one is built to solve specific operational headaches, and they often work best when they’re integrated into a single, cohesive system.

- Automated Storage and Retrieval Systems (AS/RS): Imagine a high-density storage library run by robotic librarians. That’s an AS/RS. These systems use cranes and shuttles to automatically put away and pull totes, cartons, or pallets, squeezing maximum value out of every inch of vertical space with incredible speed and precision. See how we design and implement AS/RS for smart warehouse automation.

- Autonomous Mobile Robots (AMRs): These are the next generation of warehouse transport. They are intelligent, flexible, and use built-in sensors and maps to navigate on the fly. AMRs can work right alongside your team, moving goods from storage to packing stations without needing fixed paths or guides.

- Automated Guided Vehicles (AGVs): Think of AGVs as the reliable workhorses of the warehouse. They follow predefined routes, typically guided by magnetic tape or lasers, to transport materials. They are perfect for repetitive, point-to-point jobs in a stable environment.

The Tangible Benefits Of An Automated System

Investing in automation delivers clear, measurable returns that go straight to your bottom line. While there is an initial capital outlay, it's often quickly offset by huge long-term gains in efficiency and cost savings.

The market is catching on—fast. Industry analyses estimate the global automated material handling equipment market is sitting at roughly $47.9 billion in 2024. Projections show it more than doubling to nearly $109.4 billion by 2035. That explosive growth signals a major shift in how businesses are investing in smarter, more integrated systems.

You don't have to automate everything at once, either. A phased approach makes it an accessible and scalable solution. Start with a single process, like transport or storage, and you can see the benefits firsthand. This helps you build a solid business case for further investment and strategically builds a foundation for future growth.

Ready to explore how automation can transform your facility? Our experts offer free, no-obligation layout and design consultations to show you what's possible. Request a Quote to get started.

Maximizing ROI With Smart System Integration

Getting real operational efficiency isn't about buying one fancy piece of equipment. It's about getting all your systems—racking, conveyors, forklifts, software, and even your people—to work together like a well-oiled machine. This kind of smart integration is the secret to turning individual purchases of warehouse material handling equipment into a long-term, profitable asset that actually delivers a powerful return on your investment (ROI).

It’s an approach that goes way beyond just buying a new machine. It means we have to take a hard look at your entire workflow, find the real bottlenecks, and design a system that creates a smooth, continuous flow of goods from the receiving dock all the way to shipping. The whole point is to create a setup where every component supports the next, eliminating the costly pileups and delays that absolutely kill productivity.

Thinking Beyond The Purchase Price

If you want to calculate the true ROI of new equipment, you have to look past the initial price tag. A much smarter way to look at it is the Total Cost of Ownership (TCO), which gives you a crystal-clear picture of an investment's value over its entire life. TCO factors in all the direct and indirect costs you'll encounter.

Think about things like:

- Maintenance and Repairs: What is the real cost of upkeep? How easy is it to get spare parts?

- Energy Consumption: How much is this new gear going to add to your utility bills?

- Training and Labor: What will it cost to get your team up to speed, and how much will you save in labor?

- Operational Gains: How much will faster throughput and fewer errors actually add to your bottom line?

When you analyze the TCO, you can make a much more informed decision that puts long-term value ahead of short-term savings. That’s how you turn a capital expense into a genuine profit center.

The Power Of An Intelligent Warehouse Layout

The physical layout of your facility is the foundation for your entire material handling strategy. A smart design cuts down on travel distances, reduces handling time, and makes the whole place safer. This is where a little upfront planning pays off in a big way. For example, building up with robust infrastructure like mezzanine floors can massively increase your usable storage space, directly boosting ROI by optimizing your logistics from the ground up.

A well-designed layout takes every step of your process into account:

- Workflow Analysis: We map out how products actually move through your facility to find the most efficient paths.

- Slotting Strategy: We place your high-velocity items in the most accessible spots to slash picking times.

- Aisle Configuration: We make sure your aisles are wide enough for equipment to move safely and efficiently.

A great layout doesn't just happen by accident. It's the result of careful analysis and strategic planning that aligns your physical space with your operational goals. This is the key to unlocking the full potential of your equipment investment.

This is exactly where our free design services become such a powerful tool. We help you see what a cohesive, high-performing system looks like before you spend a dime.

Integrating People And Processes

Finally, smart integration has to include your most valuable asset: your team. The most advanced equipment in the world is useless if your people aren't trained and your processes aren't clear. A successful plan includes solid training, clear standard operating procedures (SOPs), and a commitment to always getting better. This ensures your team can use the new equipment safely and effectively from day one. In fact, many managers are now digging into the true cost savings of automated inventory control to see how technology can better support their teams.

Ready to see how a fully integrated system could transform your facility? Our experts are standing by to help you design a solution that maximizes your ROI. Contact Us for a free, no-obligation layout and quote, or call us directly at (800) 326-4403.

Your Partner In Warehouse Optimization

You’ve made it this far, which means you’re serious about making your warehouse work smarter, not harder. We’ve covered the essential equipment, the critical factors to consider, and how a well-integrated system can transform your operation. Now, it’s time to put that knowledge into action.

But remember, choosing the right equipment is only half the battle. The other half is choosing the right partner to bring it all together—and that’s where we come in.

We’re More Than Just a Supplier

Think of us as an extension of your own team. When you partner with Material Handling USA, you get a dedicated ally focused entirely on your success. We handle the crucial details, offering competitive pricing and some of the fastest shipping and delivery in the industry to keep your project moving forward, on time and on budget. Every pallet rack, conveyor, and lift truck we sell is built from quality materials, ready to handle the daily grind of a busy facility.

What really makes us different is how we work with you long before you ever place an order. We know that a successful warehouse isn't built on equipment alone; it's built on a solid plan. That’s why we offer free, no-obligation quotes, layouts, and designs. Our in-house experts collaborate with you to map out an optimized workflow that makes the most of every square foot, ensuring each piece of equipment has a clear purpose.

We don't just sell you boxes off a shelf. We help you build a more efficient, safe, and profitable operation from the ground up. Think of our design service as a risk-free blueprint for unlocking your facility’s true potential.

Whether you need a few simple shelving units or a complete, fully integrated system, our team is ready to jump in. For straightforward needs, our online store has a massive selection of in-stock items ready to ship. For the more complex challenges, our consultants are here to provide the expert guidance needed to design a truly custom solution.

Take The Next Step Today

You've got the information. Let’s build the solution. We are here to help you turn your operational goals into a high-performing reality. You can start by exploring our extensive online catalog, or just give our team a call for some one-on-one support.

Ready to see what your facility can really do?

Contact Us to get your free layout and design, or Call (800) 326-4403 to talk with a specialist right now.

Got Questions? We've Got Answers

When you're looking at a big equipment purchase, a few key questions always come up. Here are the straight answers to the things our customers ask most often.

What’s the Real First Step in Choosing New Warehouse Equipment?

Before you even look at a single piece of gear, you need to do a deep dive into your own operation. The absolute most critical first step is a thorough needs analysis.

Forget the catalogs for a minute. Get a clipboard or a tablet and walk the floor. Map out your current workflow from receiving to shipping. Where are the slowdowns? What's causing them? Pinpoint your actual bottlenecks and then define what "better" looks like in clear, measurable terms. You need to know your product mix (size, weight, fragility), how many units you need to move per hour, your available footprint, and of course, your budget.

Getting all this down on paper creates a solid foundation. It's the only way to ensure the equipment you buy is a solution to your real problems, not just a shiny new piece of metal. If you're not sure where to start, our team can walk you through this process during a free consultation.

How Do I Actually Calculate ROI on This Stuff?

Thinking about ROI is smart. It is not just about the sticker price; it's about what the investment gives back to your business. At its core, you're weighing the total cost of the equipment against the money it makes or saves you over time.

"Returns" aren't just one thing. You've got direct labor savings, the extra revenue you can generate from higher throughput, and even cost avoidance—fewer injuries mean lower insurance premiums and less downtime.

The full investment includes the purchase price, but don't forget installation, training for your crew, and ongoing maintenance. A simple formula is (Net Profit / Total Investment) x 100. For a more complete picture, we also look at the payback period (how fast you recoup your cost) and the total cost of ownership (TCO) over the life of the machine.

Should I Go Manual, Semi-Automated, or Full-Auto?

There's no single right answer here—the "best" level of automation is whatever makes the most sense for your scale, complexity, and budget. The secret is often finding the right balance.

- Manual Equipment: This is your go-to for low-volume, high-variability tasks. If every order is different and flexibility is your top priority, manual is king.

- Semi-Automated Solutions: Think of this as the sweet spot. You get a serious productivity bump on repetitive tasks for a moderate investment. It’s the perfect blend of human oversight and machine efficiency.

- Fully Automated Systems: This is for the big leagues. If you're running a high-volume, high-velocity operation, full automation is how you maximize throughput and minimize long-term labor costs.

In many facilities, a hybrid approach works wonders. You might have an automated conveyor line feeding a manual packing station. The only way to know for sure is to see it mapped out. Contact us for a free layout design and we'll help you figure out the exact combination that will make your specific workflow sing.

Ready to build an operation that's more efficient, safer, and more profitable? Material Handling USA offers competitive pricing, the fastest shipping in the industry, and quality products built to last. Let our experts provide a free, no-obligation layout and quote to help you visualize the optimal solution for your facility.

Request a Quote or call us today at (800) 326-4403 to get started.