Maximize Every Cubic Foot

Unlock the full potential of your warehouse with high-density ASRS solutions.

Our systems help you reclaim vertical and horizontal space while increasing storage capacity and throughput.

Home | Full Warehouse Design Solutions | Automated Storage and Retrieval Systems (ASRS) for Smart Warehouse Automation

High-speed, multi-deep pallet handling

Fast tote and carton storage

Retrieves across multiple vertical levels

Moves pallets in all directions

Vertical access for tall racks

Semi-automated deep lane storage

Modern warehouses require more than just space—they demand intelligence, flexibility, and automation. Automated Storage and Retrieval Systems (ASRS) are built to meet these needs, offering high-density storage, faster picking, and smart inventory control for warehouses and distribution centers of all sizes.

By integrating robotics, artificial intelligence, and precision-engineered hardware, these ASRS solutions deliver unparalleled efficiency and scalability for modern logistics operations. These systems are designed to work around the clock, reduce manual labor, and improve space utilization, ultimately helping businesses lower operational costs and increase order accuracy.

By integrating robotics, artificial intelligence, and precision-engineered hardware, these ASRS solutions deliver unparalleled efficiency and scalability for modern logistics operations. These systems are designed to work around the clock, reduce manual labor, and improve space utilization, ultimately helping businesses lower operational costs and increase order accuracy.

Whether you’re a retailer managing a surge in e-commerce demand or a manufacturer with complex SKU profiles, this range of ASRS technology provides flexible options to fit your needs. Explore the six core systems below:

Unlock the full potential of your warehouse with high-density ASRS solutions.

Our systems help you reclaim vertical and horizontal space while increasing storage capacity and throughput.

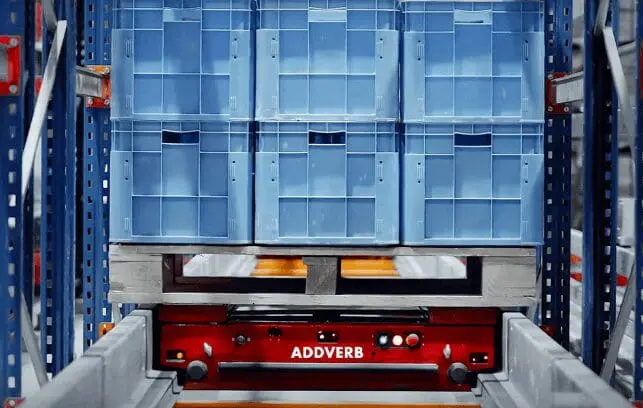

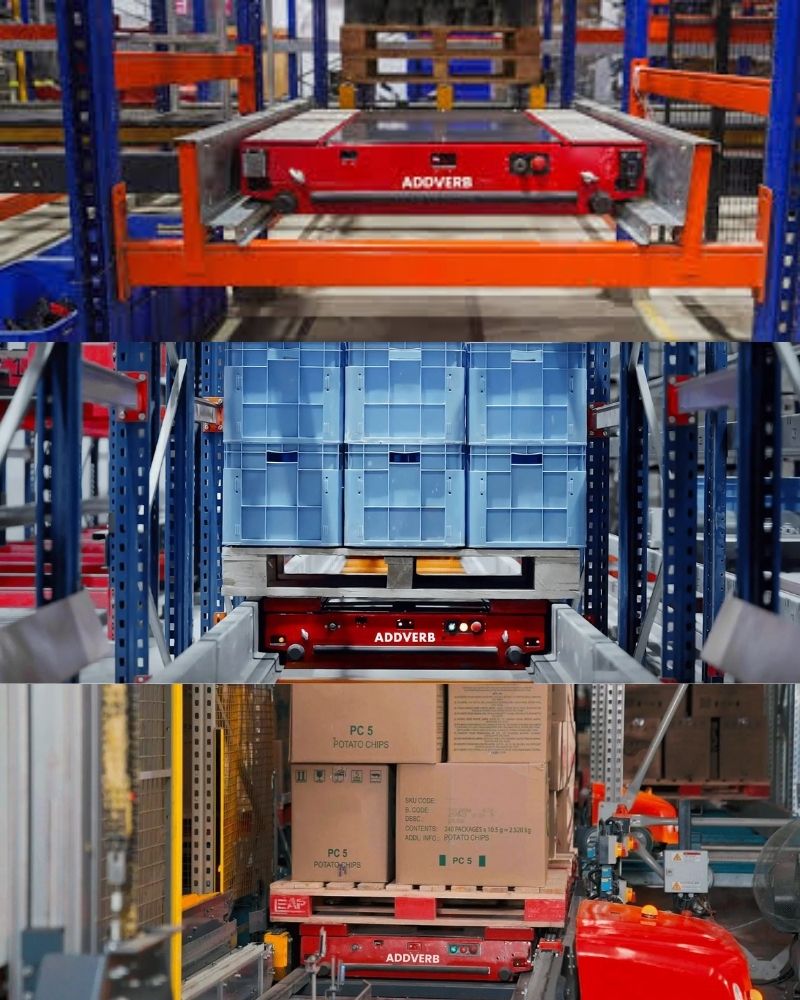

Multi-Pro is a high-throughput pallet shuttle system built for dense storage. It combines a mother shuttle that moves along a track with a child shuttle that accesses pallets individually. This combination creates a seamless flow of pallet movement within racking systems, maximizing every cubic foot of warehouse space.

Key Benefits:

Use Cases: Food & beverage, cold storage, FMCG, pharmaceutical logistics

This system is particularly valuable in cold storage facilities, where maximizing space and minimizing operator movement is critical for both energy savings and safety. Its smart controls and adaptive logic also allow it to adjust to batch profiles, optimizing throughput.

Quadron automates the storage and retrieval of cartons, crates, and totes, offering modular flexibility for varied carton sizes. Its ability to handle variable dimensions and high-speed operations makes it a cornerstone of high-volume fulfillment centers.

Specifications:

Best For: E-commerce, pharma, retail order picking, 3PLs

Quadron excels in buffer storage, sequencing, and rapid retrieval for fast-moving consumer goods. When paired with ergonomic picking stations, it drastically reduces order turnaround times and enhances worker productivity.

Medius streamlines vertical storage by accessing seven storage levels within a single aisle, reducing the need for multiple shuttles. It is especially useful in facilities with height constraints or limited floor space.

Highlights:

Applications: High-volume SKU warehouses, returns processing, reverse logistics

Its compatibility with the carton shuttle system allows warehouses to dynamically allocate resources based on throughput needs. Medius also minimizes aisle congestion by consolidating storage vertically.

Cruiser 360 redefines flexibility in ASRS by moving on both X and Y axes and transitioning levels via lift, allowing full horizontal and vertical navigation. This enables a dynamic and highly redundant system that ensures continuous operations even if part of the layout becomes inaccessible.

Features:

Benefits: Improved redundancy, optimal use of space, intelligent coordination via warehouse execution systems

Cruiser 360 is ideal for environments that experience frequent layout changes or SKU rotations. Its software integration capabilities allow for advanced planning, predictive analytics, and real-time inventory management.

Skyron is a heavy-duty crane-based ASRS ideal for tall rack systems and variable load profiles. It can operate in facilities up to 40 meters high, providing efficient access to every pallet in the system with pinpoint accuracy.

Performance Specs:

Ideal For: Automotive, chemicals, raw materials, and heavy manufacturing

Skyron stands out in environments where vertical space is abundant but lateral space is limited. It delivers smooth handling of delicate or oddly shaped loads while maintaining strict safety and quality standards.

Cruiser is a semi-automated solution for deep-lane pallet storage. It is ideal for facilities where manual handling is still required but automation is being gradually introduced.

Advantages:

Recommended For: Distribution centers, seasonal goods, large SKU batch management

Cruiser’s portability and cost-effectiveness make it an excellent starting point for businesses transitioning toward full automation. It reduces forklift travel distances and increases pallet density without requiring a full ASRS investment.

Find the right ASRS solution to maximize warehouse space, speed up fulfillment, and improve efficiency. Contact us to schedule a personalized consultation and explore how automation can elevate your warehouse performance.

Today’s ASRS solutions combine engineering excellence with cutting-edge software to deliver reliable, scalable, and data-driven warehouse automation. Key benefits include:

Real-time visibility of inventory and material flow

Modular systems tailored to your layout and business needs

Seamless integration with existing WMS and ERP platforms

Energy efficiency and reduced carbon footprint

Predictive maintenance for reduced downtime

Scalable systems that grow with your operation

These systems help warehouses lower operational costs, improve order accuracy, and scale with demand, making them an essential part of the modern supply chain.