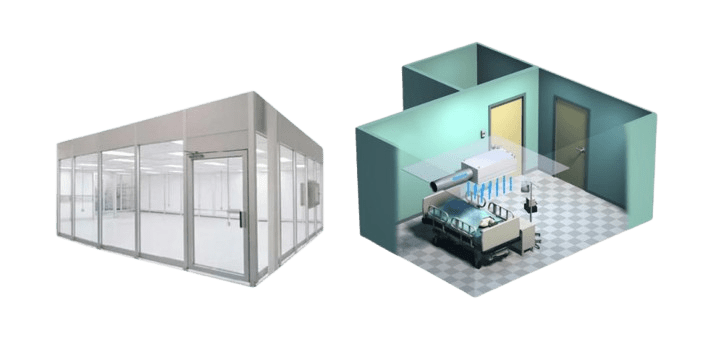

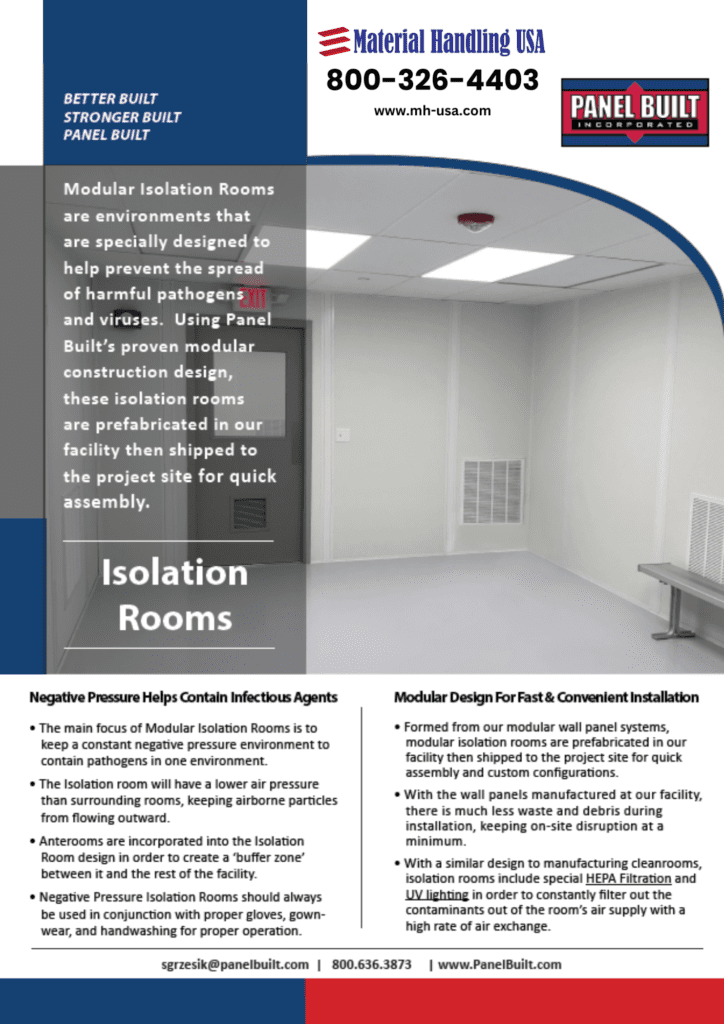

Class S Isolation Rooms

Class S Isolation Rooms, designed to maintain neutral or standard room air pressure, are essential in healthcare, research labs, and industrial settings where a clean, sterile environment is necessary. These rooms feature durable construction materials, including single-coat epoxy paint, polyethylene coating, and stainless steel, and incorporate advanced air handling systems with HEPA and ULPA filters, sophisticated fans, and alarms.