Ready to Transform Your Warehouse with Pallet Rack Safety Netting?

Enhance your space with safety netting that combines durability, flexibility, and security. Make the smart choice for your warehouse today with Pallet Rack Safety Netting!

Home | Pallet Rack Safety Netting

How Can Pallet Rack Safety Netting Transform Your Warehouse Safety?

In warehouses and distribution centers, safety is paramount. One essential tool for ensuring safety is pallet rack safety netting. This innovative solution helps prevent accidents by securing items on pallet racks, making it an indispensable addition to any storage facility.

Pallet rack safety netting creates a robust barrier that prevents items from falling off pallet racks. Typically made from heavy-duty mesh materials, this netting creates a physical barrier that helps protect workers, equipment, and inventory from potential damage. Unlike traditional knitted and woven nets, extruded polypropylene grids retain their original shape and resist sagging.

Install safety nets at the back and sides of pallet racks to create a secure enclosed area. This prevents products from sliding off the shelves while still allowing easy access for loading and unloading. Pallet rack safety netting is a crucial safety feature for any warehouse or storage facility, helping to prevent accidents and injuries. Proper installation and adherence to safety standards are essential to ensure maximum protection.

Pallet rack safety netting significantly reduces the risk of accidents by preventing items from falling off racks. This protection is crucial for maintaining a safe working environment.

Made from sturdy materials, pallet rack safety netting withstands heavy use and does not fray or unravel, even if a strand is cut. This durability ensures long-lasting protection for your warehouse.

Installing pallet rack safety netting is straightforward. With basic tools like tin snips and plastic ties, you can secure the netting in place quickly and efficiently.

Schedule a Consultation: Let Our Experts Guide You in Choosing the Perfect Pallet Rack Safety Netting for Your Warehouse

Back of Rack Protection: The netting can be installed at the back of racks to prevent items from falling off the rear side.

End of Aisle Protection: Use netting at the end of aisles to keep items contained and prevent them from falling into walkways.

Shelf Dividers: Netting can act as dividers on shelves, keeping items organized and secure.

Light-Duty Box Applications: Ideal for lighter boxes, the netting ensures that even small items remain safely on the shelves.

Installing pallet rack safety netting is a simple process:

Prepare the Netting (H3) Lay the rack guard roll on the floor parallel to the rack.

Secure the Top (H3) Pull one end of the netting to the top of the rack and wrap it around the top beam. Use cable ties to secure it.

Work Downwards (H3) Continue securing the netting down the rack, pulling it snug and using ties every four to six inches.

Trim Excess Material (H3) Once the netting is secure, use tin snips to trim any excess.

Extruded Polypropylene Grid: This type of netting retains its shape and does not sag, making it ideal for long-term use.

Nylon Pallet Rack Netting: Nylon netting is flexible and easy to install, providing a reliable barrier for various applications.

Choosing pallet rack safety netting is a proactive step towards creating a safer workplace. It helps protect employees from falling objects and reduces the likelihood of damaged inventory. Additionally, it can be tailored to fit specific needs, ensuring maximum efficiency and safety.

Investing in pallet rack safety netting is an essential step for any warehouse or storage facility. With its numerous benefits, easy installation, and customizable options, it provides a reliable solution for preventing accidents and enhancing safety. Don’t wait – take action today to secure your storage environment.

Enhance your space with safety netting that combines durability, flexibility, and security. Make the smart choice for your warehouse today with Pallet Rack Safety Netting!

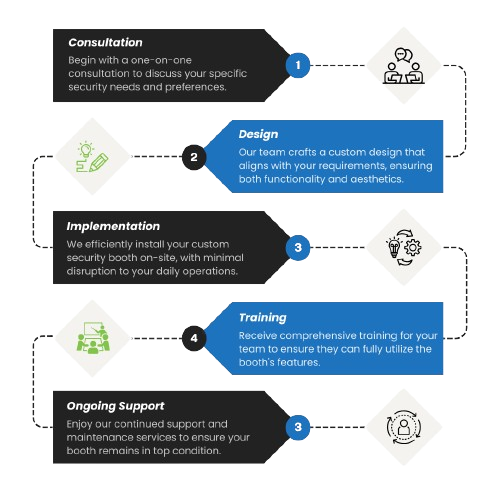

Material Handling USA guides you from consultation to implementation with personalized solutions and ongoing support.

Over 30 Years Of Experience

We design and install the right storage solutions for your specific needs

Custom

Options

We offer a range of customizable options to meet your unique needs

Customer Satisfaction

We are committed to excellent service and support, ensuring satisfaction with every purchase

Competitive Pricing

We offers competitive pricing, making it easy to find a solution that fits any budget

Tate W. Curtis

Space Coordinator, United States Department of Agriculture

“ They always available for meetings and questions, firsts, in figuring out what system would work best for our needs then by assessinh how much shelving space would be required for our existing as well as future needs, and , finally, by insuring the timely delivery and quality installation of the product. ”

Sharon L. Hancey

First District TCE of Administrative Office of the Courts

“ They were extremely attentive in assessing our needs in Logan. They provided several plans to show us our shelving options. ”

Julie Froff

Assistant Clerck of

Third District Court

“ We have been using the system now for about six moths and are happy to report that it has been a wonderful addition to our office. It is easy to operate and keeps our filing area neat and organized, and most importanly, providers us with unlemited space for growth at this time. We are completely satisfied with your product. ”

Lila Abersold

Visual Arts Coorndinator of Utah Arts Council

“ The track and system Material Handling USA recently installed is working very well Your isntallation people were able to adjust the tracks on the uneven floor in our storage space. ”

Nancy Herd

Human Resources Manager of Ray Quinney & Nebeker

“ Thank you a million times for the these killer Jazz tickets! I am just so excited to go and rub shoulders with every other "pretentious" person in Material Handling USA! How Awesome! ”

It is a mesh barrier designed to prevent items from falling off pallet racks, enhancing safety in storage facilities.

Install by securing the netting to the top beam of the rack with cable ties, working downward and trimming any excess material.

Common materials include extruded polypropylene and nylon, chosen for their durability and strength.

Yes, it can be cut to fit specific dimensions and requirements, ensuring a perfect fit for your storage needs.

Benefits include enhanced safety, durability, easy installation, and the ability to prevent accidents and damage.

Install netting at the back and sides of racks, end of aisles, and as shelf dividers for maximum protection.

Yes, it is suitable for various settings, including warehouses, distribution centers, and manufacturing plants.

By creating a barrier, it prevents items from falling and causing injuries or damage, ensuring a safer work environment.

While primarily designed for indoor use, some netting materials are suitable for outdoor applications, depending on the environment.

Regular inspections are recommended to ensure the netting remains intact and effective.

NationWide Shelving offers high-quality, tear-drop design pallet racks compatible with major manufacturers such as Interlake, Space Rack, USP, Lodi Metal-Tech, Steel King, and Husky.

Uprights:

Beams:

Decking Options:

Accessories: