Shrink Wrap Machines

By applying heat to shrink the film around items, shrink wrap machines effectively protect products from dust, moisture, and damage. This comprehensive guide will take you through everything you need to know about shrink wrap machines, including their various types, materials used, benefits, and industry applications.

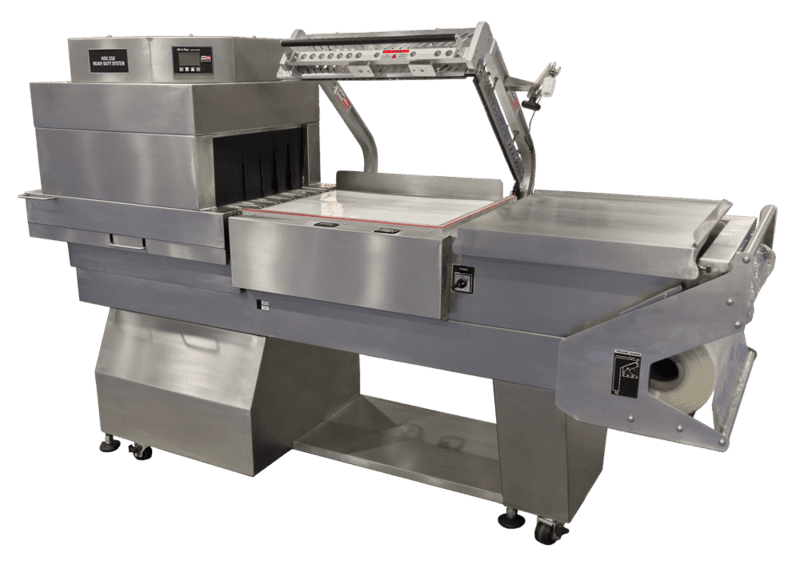

SHRINK WRAP MACHINE

Shrink wrap machines are essential in various industries for packaging products securely and efficiently. These machines use heat to shrink a plastic film around items, creating a tight, protective seal. Let's explore the different types of shrink wrap machines, their uses, and the benefits they offer.

SHRINK WRAP MACHINE

Manual Shrink Wrap Machine

Manual shrink wrap machines require manual operation to wrap and seal products. These are ideal for small businesses or low-volume packaging needs.

Semi-Automatic Shrink Wrap Machine

Semi-automatic machines offer a balance between manual and automatic operations. They require some manual intervention but can handle larger volumes than manual machines.

Automatic Shrink Wrap Machine

Automatic shrink wrap machines are fully automated, making them perfect for high-volume packaging operations. They offer maximum efficiency and speed.

Benefits of Shrink Wrap Machine

Protection

Shrink wrap provides a protective barrier against dust, dirt, moisture, and tampering. It can help extend the shelf life of products, particularly in the food industry.

Security

Once the shrink wrap is applied, it creates a tamper-evident seal. If the wrap is broken or disturbed, it’s obvious that the product has been tampered with.

Cost-Effective

Shrink wrapping can be more economical compared to other packaging methods. The materials used are often less expensive, and the process can reduce labor costs, especially with automatic or semi-automatic machines.

Versatility

Shrink wrap can be used for a wide range of products, regardless of size or shape. From small items like DVDs and books to large items like pallet loads, shrink wrap can handle it all.

Space Saving

The tight seal of shrink wrap means that products can be packed more densely, saving storage and shipping space.

Aesthetic Appeal

Shrink wrap is clear and can enhance the appearance of the product. It offers a clean, professional look that can attract customers

Frequently Asked Questions (FAQ)

A shrink wrap machine is a device that applies heat to shrink a plastic film tightly around products for packaging.

Assess your facility’s size, type of flooring, and cleaning frequency. Consult with experts for personalized recommendations.

There are manual, semi-automatic, and automatic shrink wrap machines, each designed for different packaging needs.

Benefits include enhanced protection, improved aesthetics, and cost-effective packaging.

Consider factors such as volume of packaging, product size, and budget when selecting a shrink wrap machine.

Yes, most shrink wrap machines can accommodate various product sizes, but it’s essential to choose one that fits your specific needs.

Shrink wrapping can be environmentally friendly if you use recyclable shrink films and minimize waste.

The cost of shrink wrap machines varies depending on the type and features. Manual machines are generally more affordable than automatic ones.

Regular maintenance, such as cleaning and inspecting parts, is necessary to ensure optimal performance and longevity of the machine.

Shrink wrap machines are available from various suppliers and online retailers. Research and compare options to find the best machine for your needs.

CALL US NOW!

Have questions or need assistance in choosing the right machine? Contact our experts for a free consultation and personalized recommendations. Simply email us at Sales@MH-USA.com or use our convenient "Contact Us" form to get started. You can also give us a call at 1-800-326-4403