Improving warehouse efficiency isn’t just about tweaking a few processes. It's a continuous journey of optimizing your space, refining how your team works, and empowering them with the right tools. It means moving beyond old-school manual systems to embrace strategic layouts, smart storage, and streamlined fulfillment that actually keeps up with demand.

The real goal here is to transform your facility from a cost center into a competitive advantage. When you increase throughput, slash error rates, and create a safer, more productive environment, that’s exactly what happens.

Confronting Modern Warehouse Pressures

If you're feeling the squeeze, you're not alone. The explosive growth of e-commerce and a persistent labor shortage have put immense strain on warehouse operations in every industry imaginable. Many managers are hitting a wall, realizing their manual processes simply can’t keep pace with customer expectations for speed and accuracy.

This isn’t just a feeling; the numbers paint a stark picture. A staggering 63% of warehouses worldwide are still fully manual, relying on paper records and basic shelving. This heavy dependence on manual work often leads to error rates as high as 1 in every 1,000 picks. For a mid-sized facility, that translates into thousands of lost hours every single year. You can read the full research on integrated warehouse systems to see just how deep this challenge runs.

Why Manual Systems Fall Short

The problems created by outdated, manual systems go way beyond simple inefficiency. They create a domino effect that impacts your entire supply chain and, ultimately, your bottom line.

Here are the operational hurdles we see time and again:

- Increased Labor Dependency: Manual picking, packing, and sorting are incredibly labor-intensive. This leaves your operation vulnerable to staffing shortages and the sting of rising labor costs.

- Higher Error Rates: Human error in picking and inventory counts leads to incorrect shipments, costly returns, and worst of all unhappy customers.

- Wasted Space: Without optimized storage systems, valuable vertical and horizontal square footage is often squandered. This limits your capacity and can force a premature, and very expensive, expansion.

- Crippling Bottlenecks: A lack of standardized processes creates choke points, especially during peak seasons. These bottlenecks can slow down your entire fulfillment cycle, from receiving to shipping.

The Path Forward

Tackling these pressures requires a fundamental shift in thinking. Improving warehouse efficiency isn't about finding a single magic bullet. It’s a deliberate process built on several key pillars: intelligent layouts, advanced storage solutions, streamlined fulfillment methods, and the smart integration of technology.

Throughout this guide, we'll lay out a practical roadmap to navigate this transformation. The businesses that get a head start on this planning process are the ones best positioned to secure faster installation timelines and avoid the costly delays that come with frantic, unplanned growth.

The goal is to create a resilient, high-performance environment where every square foot, every employee, and every minute is used effectively. This journey turns operational challenges into opportunities for significant growth and profitability.

Ready to see what’s possible for your facility? Our specialists can provide a free, no-obligation quote and layout design to help you visualize the potential. Give us a call at (800) 326-4403 to start the conversation.

Building Your Foundation With Smart Layout And Storage

Think of your warehouse layout as the blueprint for your entire operation. Every single move from the moment goods hit your receiving dock to when they’re shipped out is dictated by the physical flow of your space. A poorly planned layout creates a maze, forcing your team to take longer routes, which burns through time and energy.

It’s a bigger deal than you might think. For many operations, travel time eats up more than 50% of a picker's entire day. A strategic layout, however, turns that maze into a direct highway, slashing non-productive movement and building a more logical workflow. Getting your physical space optimized is the single most critical step you can take, as it sets the stage for every other improvement you’ll make.

Maximizing Space With The Right Storage Systems

Once your workflow is mapped out, the next move is to choose storage systems that actually fit your inventory and throughput goals. The right setup doesn't just hold your products; it makes them easier to access, safer to handle, and simpler to track. Making the right choice here is what prevents bottlenecks and keeps your team moving without hitting roadblocks.

If you’re juggling a wide variety of SKUs with high turnover, selective pallet racking is almost always the answer. It gives you immediate, direct access to every single pallet. No more shuffling inventory around just to get to what you need. That direct access is a game-changer in fast-paced environments where speed and accuracy are everything.

But what if your problem isn't access, but just plain running out of room? Before you start pricing out a costly expansion, look up. Industrial mezzanines can literally double your usable square footage by tapping into that unused vertical space. They’re perfect for adding more storage, dedicated work areas, or even in-plant offices without touching your building's footprint.

Choosing The Right Storage System

Selecting the right storage isn't a one-size-fits-all decision. It demands a hard look at your inventory profile, pick frequency, and long-term growth plans. This table breaks down some of the most common solutions to help you match the system to your operational reality.

| Storage Solution | Best For | Key Benefit | MH-USA Product |

|---|---|---|---|

| Selective Pallet Racking | High SKU variety, fast-moving inventory | Direct access to every pallet | Pallet Racking Systems |

| Mezzanines | Utilizing vertical space for storage or offices | Doubles floor space without expansion | Industrial Mezzanines |

| Mobile Shelving | High-density storage, low-access items | Maximizes storage capacity in a small footprint | Mobile Aisle Shelving |

| Modular Buildings | Creating controlled environments or offices | Fast, flexible, and scalable build-outs | Modular Buildings & In-Plant Offices |

Each of these systems solves a different problem, so the key is to identify your biggest constraint whether it’s SKU accessibility, floor space, or the need for a controlled environment and choose accordingly. For a deeper dive, you can learn more about how to improve warehouse designs in our detailed guide.

Specialized Solutions for Unique Needs

Sometimes, standard racking and shelving just don't cut it. You might need a secure, controlled environment right inside your larger facility. That’s exactly where modular buildings and in-plant offices shine. They offer a quick, flexible way to create secure zones for high-value inventory, clean rooms, or administrative offices directly on the warehouse floor.

These structures go up way faster and with far less disruption than traditional construction. Better yet, as your business evolves, they can be reconfigured, expanded, or even moved, giving you a level of adaptability that permanent walls just can't offer. And to keep things running smoothly inside these spaces, a solid maintenance routine, including a comprehensive forklift inspection checklist, is essential for safety and performance.

A well-designed space is your first and most impactful step toward peak productivity. By matching your layout and storage systems to your operational reality, you create an environment where efficiency becomes the standard, not the exception.

The businesses that get this foundational planning right are the ones that can scale smoothly, securing faster installation timelines and avoiding the growing pains that derail their competitors. Our team offers free layouts and designs with no obligation, helping you visualize these critical improvements without any commitment. Request a Quote today and let's see how a smarter layout can transform your warehouse.

Refining Your Order Fulfillment Process

So, your warehouse layout is dialed in and your storage is optimized. Fantastic. Now, let’s get to the real heart of the operation: getting orders out the door. The efficiency of your picking, packing, and shipping processes is what your customers actually feel. Get it right, and they’re happy. Get it wrong, and all that hard work organizing your facility can go right out the window.

That critical journey from a customer clicking "buy" to a package leaving your dock is where small, smart improvements can lead to massive gains. We're talking about creating a seamless workflow that pushes throughput and accuracy sky-high.

Optimizing Order Picking Methods

Order picking is almost always the most labor-intensive and therefore expensive part of warehouse operations. Picking the right strategy is a huge deal, and trust me, there's no single "best" method. The ideal choice comes down to your order volume, SKU variety, and the physical layout of your building.

Here’s a breakdown of the most common approaches I see in the field:

- Single Order Picking: This is the old standby. One picker, one order, one trip. It’s simple and great for small outfits or those really complex, multi-line orders that need special attention. But for most, it's the slowest way to go.

- Batch Picking: A real game-changer for efficiency. A picker grabs items for a bunch of different orders all at once. By grouping orders that share common SKUs, they make one trip to a location and pick items for several customers. You can see a huge jump in lines picked per hour with this method.

- Zone Picking: Think of it like a factory assembly line. You divide the warehouse into zones, and pickers stay within their assigned area, picking only the SKUs located there. Orders get passed from one zone to the next until they're complete. This works beautifully in large facilities with a high volume of orders.

- Wave Picking: This is a hybrid approach, combining bits of zone and batch picking. You release orders in a scheduled "wave," often grouped by a specific shipping carrier or delivery route. It’s all about coordinating the picking and packing to hit those critical carrier pickup deadlines.

Streamlining Packing and Shipping

Once an order is picked, the handoff to packing has to be airtight to prevent bottlenecks from forming. I’ve seen it happen a hundred times: a fast picking team gets held up by a slow packing station.

An efficient packing station isn't just a table; it's an ergonomic command center built for speed. Everything a packer needs from scanners and tape guns to void fill should be within arm's reach.

You need a steady supply of durable corrugated boxes, strapping, and labels right there. Pro tip: standardize your box sizes as much as possible. This makes it way faster for packers to choose the right one and helps create tighter, more stable pallets for shipment.

A well-organized packing area cuts down on wasted movement and reduces physical strain on your team. That means higher productivity and better morale. And in the end, a slick fulfillment process is how you proactively improve ecommerce customer experience, which is what this is all about.

A critical tactic for boosting picking speed is creating a 'golden zone' for your fastest-moving items. This zone, typically located between a picker's waist and shoulders in the aisles closest to the packing stations, ensures your most popular products require the least amount of travel and effort to pick.

The warehouses that get these fulfillment details right are the ones that are ready to scale. By making sure your entire outbound workflow is supported from quality racking to the right shipping supplies you're building a system that can handle growth. We dive even deeper into this in our article on how to save time picking fast movers.

Implementing Lean Principles For Continuous Improvement

Once your order fulfillment process is humming along, it's time to shift focus from a one-time fix to building a culture of continuous improvement. This is where lean methodologies, particularly the 5S system, provide a powerful, practical framework. Think of it as a systematic way to organize your workspace to slash waste, prevent errors, and set a new standard for how your facility runs.

The 5S system isn't a project you complete and forget; it's a philosophy. When your team truly adopts it, the result is a safer, more organized, and fundamentally more productive environment. An organized warehouse is one where team members find what they need, when they need it, without wasted steps or confusion.

Breaking Down The 5S System

The 5S methodology is made up of five distinct phases. Each one builds on the last, creating a cycle of positive reinforcement that keeps getting stronger. Let's break down how each principle applies directly to a real-world warehouse setting.

Sort (Seiri): The first step is all about decluttering. Walk through every work area and remove anything not essential for current operations. This means getting rid of broken pallets, obsolete inventory, old equipment, and redundant tools. The goal here is simple: free up valuable space and eliminate distractions.

Set in Order (Seiton): With only the necessary items left, the next phase is to find a logical, permanent home for everything. This is about creating designated storage locations for tools, supplies, and equipment. For example, using clearly labeled bins on mobile aisle shelving for spare parts or outlining tool placements on a shadow board ensures anyone can find what they need in seconds.

Shine (Seiso): This is so much more than just cleaning. It’s about using the act of maintaining a clean workspace as a form of inspection. When teams perform daily cleaning routines on equipment and work areas, they start spotting potential problems like an oil leak on a forklift or wear on a conveyor belt long before they cause expensive downtime.

Standardize (Seiketsu): Here, you create the rules and procedures to maintain the first three S's. This involves developing standard operating procedures (SOPs), checklists, and clear visual cues. Using floor marking tape to define walkways or posting easy-to-read signage helps ensure everyone follows the same efficient and safe processes, every single time.

Sustain (Shitsuke): Let's be honest, this is the hardest step. It's about making the 5S principles a habit and weaving them into the very fabric of your company culture. Regular audits, ongoing training, and visible support from management are absolutely crucial to prevent the team from sliding back into old, disorganized habits.

The Link Between Safety and Efficiency

It's a huge mistake to view safety and efficiency as separate goals. The reality is, they are two sides of the same coin. An organized, lean warehouse is inherently a safer one. When walkways are clear, tools are properly stored, and processes are standardized, the risk of accidents plummets.

A safe warehouse is a productive warehouse. Every accident, no matter how minor, results in downtime, potential workers' compensation claims, and a hit to morale all of which directly impact your bottom line.

Integrating safety equipment is a core part of any smart lean strategy. Installing guard rails protects both people and equipment from forklift traffic. Secure wire security cages can be used to control access to high-value inventory or hazardous materials. These aren't just safety add-ons; they are direct investments in your operational continuity.

By embedding these lean principles, you empower your team, cut down on costly errors, and build a more resilient operation. The businesses that focus on building this culture now are the ones that can adapt faster to challenges and scale their operations without descending into chaos. To see how our products can support your safety and organizational goals, Contact Us for a free consultation.

Integrating Technology To Work Smarter

Let's be honest, the word "automation" can sound intimidating and expensive. Many managers picture a massive, disruptive overhaul that costs a fortune. But in reality, technology is no longer just a nice-to-have; it's a core driver of a modern, efficient warehouse. The most successful operations get there with a practical, phased approach. You don't need a fleet of robots on day one to see a huge impact.

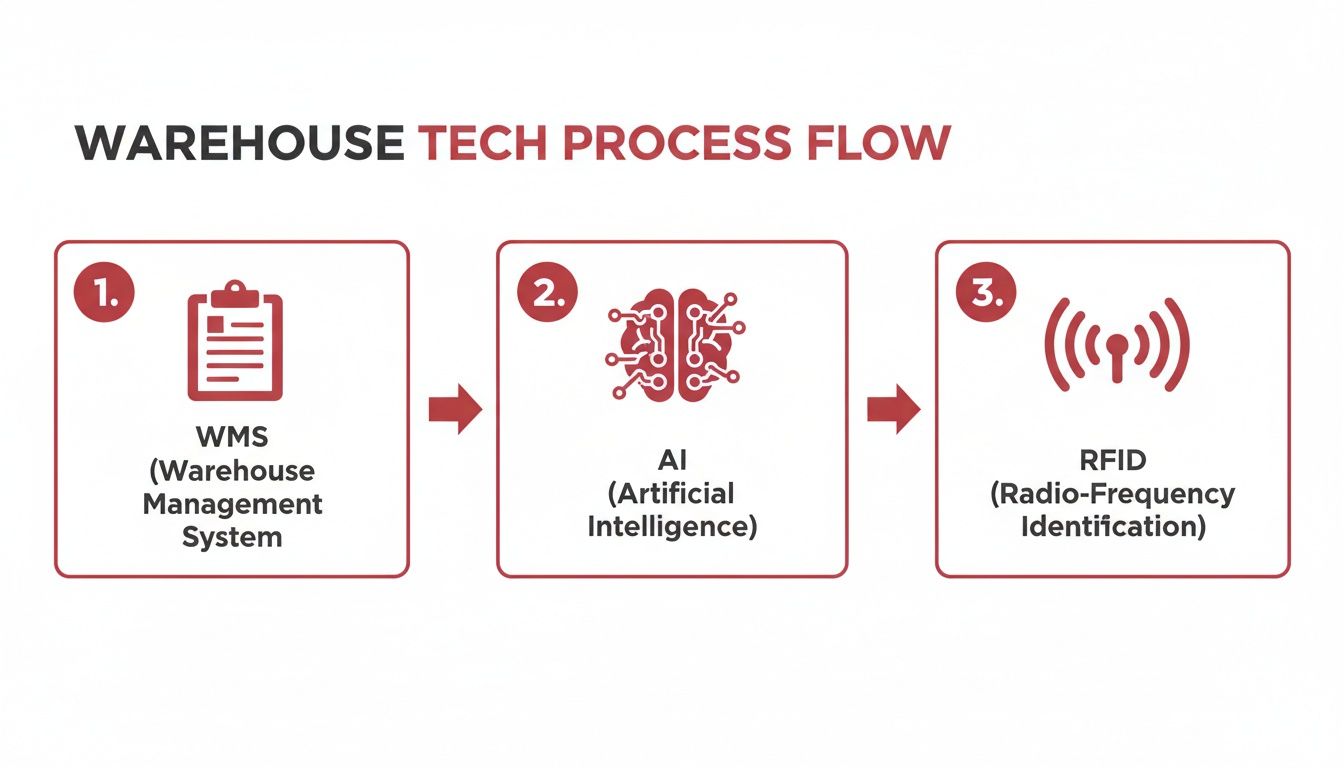

The most logical place to start is almost always with a solid Warehouse Management System (WMS). A good WMS is like turning the lights on it gives you immediate, real-time visibility into your inventory, orders, and workflows. It becomes your single source of truth, eliminating the guesswork and giving you the hard data needed to make smarter, faster decisions.

Building on a Digital Foundation

Once your WMS is humming along, you can start layering in more advanced tools that feed off that data. This is where things get really powerful. For instance, AI-powered analytics can chew through your historical sales data and current trends to completely optimize your inventory placement. It can tell you exactly where your fastest-moving SKUs should be slotted to slash travel time for your pickers.

This level of insight goes beyond just organizing your current stock. It helps you predict future demand with surprising accuracy. Imagine knowing that certain products are about to surge for an upcoming holiday, allowing you to proactively adjust stock levels and staff up accordingly. That's the power of building intelligent technology on a solid digital foundation.

Achieving Near-Perfect Accuracy

We've all been there: the dreaded manual inventory count. It's a time-consuming, error-prone process that most operations have to suffer through. This is an area where technology like Radio-Frequency Identification (RFID) can be a game-changer. By tagging pallets or even individual items, you can get to near-perfect inventory accuracy without the painstaking manual labor.

An RFID system lets you scan entire sections of your warehouse in a fraction of the time, instantly reconciling what's physically on the shelf with what your WMS thinks is there. The time saved is significant, but the real win is the confidence you gain in your data. Better data means fewer stockouts, less overstocking, and happier customers.

The key takeaway is that automation isn't an all-or-nothing investment. Small, strategic integrations, chosen to solve your most pressing bottlenecks, can deliver significant and measurable returns.

Phased Automation for Sustainable Growth

Many managers hold back on technology because they fear the upfront cost and operational headaches. A much smarter path is a phased implementation that aligns with your specific business goals and budget.

Here’s a common-sense roadmap for what that could look like:

- Phase One – Visibility and Control: Start with a robust WMS to digitize your inventory and order management. This is the bedrock.

- Phase Two – Accuracy and Speed: Introduce barcode or RFID scanning to sharpen picking accuracy and make the receiving process flow smoothly.

- Phase Three – Advanced Optimization: Explore AI analytics for demand forecasting or implement conveyor systems to cut down on manual transport in high-traffic zones.

- Phase Four – Robotics and Automation: Once your processes are standardized and running like clockwork, consider Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs) for goods-to-person picking.

The industry is already moving fast. By 2026, automation and AI are set to fundamentally change warehouse operations. Forecasts predict that AI-driven solutions will become an operational must-have, cutting error rates by up to 50% and boosting throughput by 30-40%. The businesses planning for this shift now are the ones who will have a serious competitive edge.

Our products are designed from the ground up to complement this technological evolution. The pallet racking, mezzanines, and modular buildings you install today are built to integrate seamlessly with the automation you add tomorrow. To see how this works, check out our guide on how to future-proof your operations with smart warehouse automation design. This ensures the infrastructure you build isn't just for today, but ready for the innovations that will define the future of logistics.

Your Next Steps Toward a High-Performance Warehouse

We’ve walked through the key strategies for whipping your warehouse into shape, from overhauling your layout and processes to bringing in lean principles and smarter tech. Seeing these improvements isn't just a fantasy; it delivers a real, tangible return through better productivity, tighter accuracy, and healthier profits.

The path forward is all about orchestration driven by data and having clear, real-time visibility into what’s happening on your floor. It’s no secret that this approach is set to slash warehouse inefficiencies by up to 40%. In fact, industry leaders are already hitting 99% on-time delivery by tapping into IoT and analytics. While only 23% of warehouses have fully integrated their systems, a whopping 75% of experts agree it's the only way to unlock that next level of performance. You can dig deeper into warehouse and transportation trends to see where the competition is headed.

This diagram shows the typical tech adoption flow, starting with the foundational systems and building up to advanced tracking and analytics.

You can see how each layer builds on the last, creating a powerful, cohesive system for total visibility and control.

Taking Action on Efficiency

Here’s a tip from experience: businesses that start the planning process now almost always secure better installation timelines and sidestep the operational chaos that comes with a sudden growth spurt. If you wait until you're bursting at the seams, you’re forced into rushed decisions and disruptive projects that throw a wrench into your daily operations.

The most successful warehouses aren't the ones that make a single, massive change. They're the ones that commit to a journey of continuous, strategic improvement. When you take the next step, you're investing in the long-term health and scalability of your entire operation.

It’s time to transform your facility from a cost center into a high-performance asset. Our specialists are ready to provide a free, no-obligation quote and layout design to help you see the untapped potential in your current footprint. It's the perfect way to explore a clear path forward without any upfront investment.

We can help you pinpoint your unique challenges and map out a practical plan that works for you. Let our experience guide you toward the success that a truly efficient warehouse can bring. Contact Us today or give us a call at (800) 326-4403 to get the conversation started.

Warehouse Efficiency FAQs

When you're staring down the barrel of an efficiency project, a lot of questions pop up. We get it. Here are some quick, no-nonsense answers to the most common queries we hear from warehouse managers on the front lines.

Where’s The Best Place To Start Improving Warehouse Efficiency?

Start with what you can see. Before you even think about software or fancy gadgets, take a hard look at your warehouse layout and product slotting. Inefficient travel paths for your pickers are absolute time-killers. A great first step is to literally draw it out a simple spaghetti diagram tracking one picker's movement for an hour can be a real eye-opener, revealing massive opportunities for improvement.

Once you see the paths, look at the products. Dig into your inventory data and find your fastest-moving items, what we often call your 'A' items. Are they tucked away in the back corner? They shouldn't be. Make sure they're stored in the most accessible spots, as close to your packing and shipping stations as possible. Nailing your layout and slotting first creates a solid foundation for every other gain you'll make.

How Can I Improve Efficiency Without A Big Tech Investment?

You can make huge strides without spending a fortune on technology. The biggest wins often come from process improvements. Start by embracing lean principles like the 5S methodology. Just by organizing the workspace, getting rid of clutter, and making sure every tool has a home, you can slash the time your team wastes searching for things.

Next, rethink your picking strategies. If you're still doing single-order picking, switching to a basic batch picking process can dramatically boost the number of lines picked per hour with zero new tech. Also, don't overlook your packing stations. Investing in quality, ergonomic stations and ensuring all your shipping supplies boxes, tape, labels are within arm's reach can eliminate some of the most frustrating bottlenecks in your entire operation.

So many managers get distracted by shiny high-tech solutions, but mastering the fundamentals of layout, slotting, and picking methods often delivers 80% of the results for 20% of the cost.

How Do I Measure The ROI Of Efficiency Improvements?

You can't know if you've improved if you don't know where you started. To measure your Return on Investment (ROI), you absolutely have to establish baseline metrics before you change anything. This is where your Key Performance Indicators (KPIs) become your best friend.

Focus on tracking a few critical numbers:

- Order Picking Accuracy: What percentage of your orders go out the door with zero errors?

- Cost Per Order: What's the total fulfillment cost divided by the number of orders you ship?

- Inventory Turnover Rate: How many times do you sell through your entire inventory in a given period?

- Order Cycle Time: What's the total time elapsed from the moment an order is placed to the moment it ships?

After you implement a change maybe you've installed a new racking layout or switched to a zone picking strategy track these same KPIs for a set period. Calculating the ROI is then a straightforward comparison of the financial gains (like increased throughput and fewer errors) against what you spent. For example, you'd weigh the value of labor hours saved plus the cost of mis-picks avoided against the cost of your new shelving.

Ready to turn these insights into action? Material Handling USA offers free, no-obligation quotes and layout designs to help you visualize the potential in your facility. Contact Us or call (800) 326-4403 to discuss your unique challenges with our specialists.