In a world overflowing with complex packaging options, there's a reason bulk packing peanuts are still a go-to for fulfillment centers. They hit the sweet spot of balancing cost, protection, and operational speed. This classic void fill is all about cushioning products, stopping them from shifting around in transit, and absorbing impacts—directly cutting down your damage rates and protecting the bottom line.

Whether you’re using traditional EPS or the newer biodegradable types, packing peanuts aren't just filler. They're a strategic asset for keeping your shipping lines moving and your customers satisfied.

Why Bulk Packing Peanuts Are Still a Smart Choice

For any manager overseeing warehouse operations, the choice of void fill isn't just a line item on a budget. It's a critical decision that affects productivity, product integrity, and profitability. While new packaging solutions appear regularly, bulk packing peanuts have remained a stubbornly reliable and cost effective way to secure goods.

Their job is simple but effective: create a protective cushion that immobilizes items inside a shipping box. This prevents products from colliding with each other or the box walls during the inevitable bumps and drops of the shipping journey. On top of that, their light weight helps keep shipping costs down—a significant advantage when you're moving high volumes.

Core Benefits for Modern Warehouses

Making the right call on void fill is fundamental to a smooth running operation. Bulk packing peanuts bring several key advantages to the table that keep them relevant in today's fast paced fulfillment centers.

- Exceptional Cushioning: The unique interlocking shape isn't just for looks. It creates a dense yet flexible barrier that’s fantastic at absorbing shock and vibration.

- Total Versatility: They work for almost anything. From delicate electronics to odd shaped machine parts, peanuts can fill voids of any size or shape with no problem.

- Cost Efficiency: When you break it down on a per cubic foot basis, packing peanuts are one of the most economical void fill options available. The savings on supply costs can be significant.

Choosing the right void fill isn’t just buying a material; it’s an investment in a system. A system that ensures products arrive safely, which directly builds customer loyalty and cuts down the expensive headache of managing returns.

When you're dealing with particularly delicate items, knowing exactly how to protect them is crucial. For more detailed advice, check out these expert tips on How to Pack Fragile Items for Moving.

In the end, the lasting appeal of bulk packing peanuts comes down to their simplicity and reliability. They are a proven solution for protecting shipments, helping your facility maintain a high standard of quality from the packing station to the customer's doorstep. Ready to explore your options? Contact Us for a free quote and consultation.

Choosing Between Traditional and Biodegradable Peanuts

When you're deciding between traditional Expanded Polystyrene (EPS) and biodegradable packing peanuts, you’re making a call that affects more than just your budget. This choice impacts your brand, your operational priorities, and the experience you create for your customers. It's not just about filling a box; it's about balancing cost, performance, and perception.

Let's break down the two main options. Both get the job done—protecting your goods during their journey—but they approach it from completely different angles. Understanding these differences is the first step to picking the right void fill for your products and your business.

The Case for Traditional EPS Peanuts

Traditional EPS packing peanuts are the workhorses of the shipping world, and for good reason. Made from expanded polystyrene, they deliver high performance cushioning while being exceptionally lightweight, making them a go to, cost effective option for high volume shippers. Their classic "S" shape is engineered to interlock, creating a secure nest that stops products from shifting in transit.

Key advantages of EPS peanuts include:

- Superior Shock Absorption: Their structure is designed to compress and absorb impact, providing excellent protection for fragile or heavy items.

- Moisture Resistance: Unlike plant based alternatives, EPS peanuts are unaffected by humidity or moisture, ensuring consistent performance in any shipping condition.

- Cost Effectiveness: On a per cubic foot basis, traditional peanuts often have the lowest upfront cost, a major factor for large scale operations.

For businesses where rugged performance and a sharp eye on the bottom line are the main drivers, traditional bulk packing peanuts are still a compelling choice.

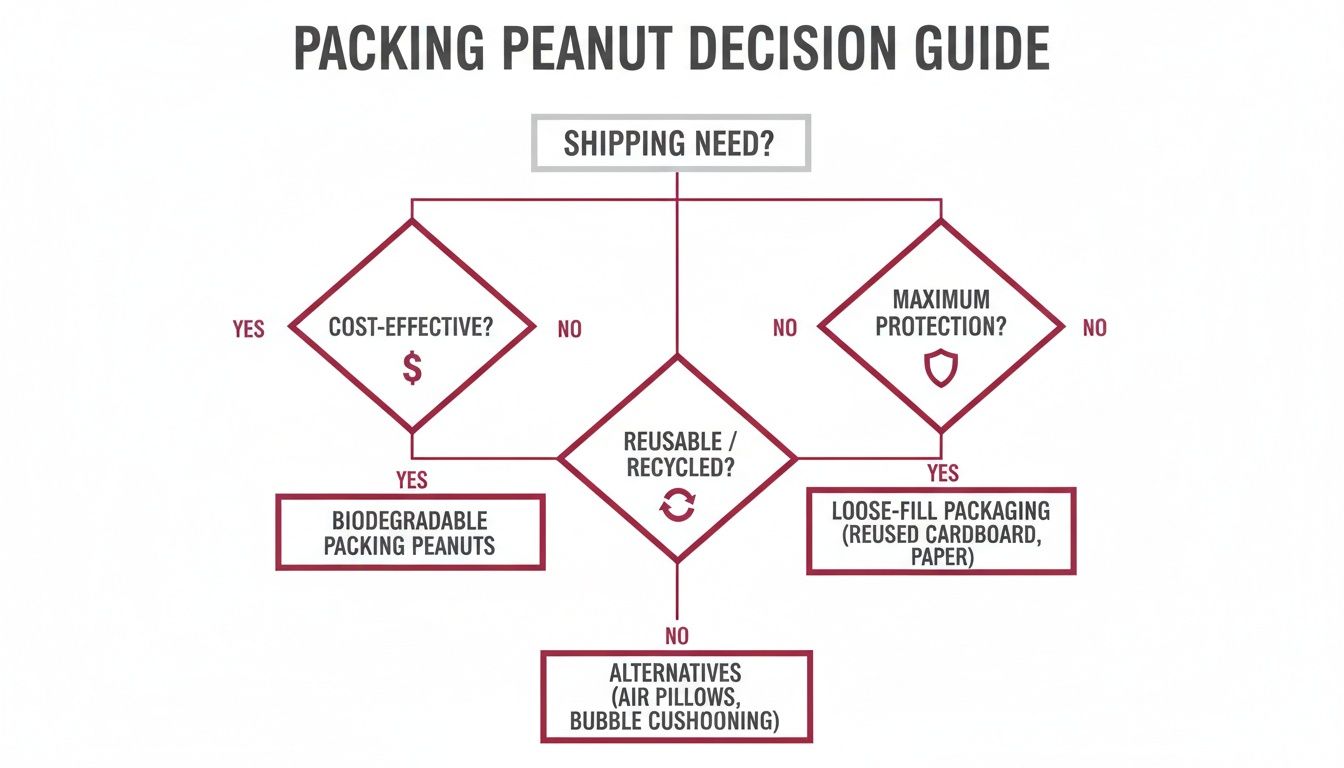

This flowchart gives you a straightforward way to think through the decision based on what matters most to you, whether that's cost, protection, or something else.

As you can see, prioritizing factors like sustainability or the customer unboxing experience can steer you toward different, but equally valid, void fill solutions.

The Rise of Biodegradable Peanuts

On the other side, you have starch based biodegradable peanuts. These eco friendly alternatives are designed to provide solid protection while tackling environmental concerns head on. Their most distinct feature? They dissolve in water. This makes disposal incredibly easy for your customer and helps create a cleaner, more positive unboxing experience.

Choosing biodegradable peanuts can directly align your packaging strategy with your company's sustainability goals, a factor that is increasingly important to consumers.

The move toward greener packaging is not just a trend; it's a significant market shift. Driven by environmental concerns, the biodegradable packing peanuts market is expected to expand from $240.8 million to $559.7 million by 2034, growing at an impressive CAGR of about 8.8%. You can learn more about these biodegradable packaging trends and their market growth.

This kind of growth signals a clear shift in what businesses and consumers want, making biodegradable options a forward thinking choice.

Head to Head Comparison

To make the right call, it helps to see the features lined up side by side. Each type of packing peanut has its own strengths that make it a better fit for certain situations.

Comparison of Packing Peanut Types

This table breaks down the key differences to help you make an informed decision.

| Feature | Traditional EPS Peanuts | Biodegradable Peanuts |

|---|---|---|

| Material | Expanded Polystyrene (Petroleum based) | Plant Starch (e.g., corn, potato) |

| Protection | Excellent for heavy, fragile items | Good for light to medium weight items |

| Moisture | Resistant to water and humidity | Can degrade if exposed to moisture |

| Disposal | Reusable, but requires special recycling | Water soluble, compostable, biodegradable |

| Static | Can generate static cling | Naturally anti static |

| Cost | Generally lower upfront cost | Often a slightly higher initial investment |

The final verdict comes down to balancing your product's needs, shipping distances, sustainability goals, and the message you want to send your customers. If your products are heavy and need maximum resilience, EPS might be your best bet. But if your brand champions environmental responsibility and your products are on the lighter side, biodegradable peanuts are an excellent fit.

Considering a switch or just need to stock up? We offer competitive pricing and the fastest shipping in the industry. Request a Quote today or Call (800) 326-4403 to speak with a specialist.

Figuring Out Your Bulk Packing Peanut Needs

Getting a handle on how many bulk packing peanuts you actually need is what separates amateurs from professionals. Guess wrong, and you’re either tying up cash and valuable warehouse space with excess inventory, or you’re scrambling to find void fill during a rush, bringing your shipping line to a halt.

Let's get this right. The goal is to stop guessing and start calculating. Once you know your numbers, you can dial in your purchasing schedule, cut down on waste, and make sure your team always has what they need to keep packages moving. It's about being proactive, not reactive.

The Basic Formula for Nailing Your Numbers

At the end of the day, you're just measuring empty space. You need to figure out the total volume of the void you’re filling across all your typical shipments. Even though every box is a little different, you can get a surprisingly accurate estimate by working with averages.

Here’s a simple formula that works for just about anyone:

(Average Box Volume − Average Product Volume) × Number of Shipments = Total Peanuts Needed

This will give you a solid baseline number in cubic inches or feet. From there, it's easy to figure out how many bags you need to order, making sure your next purchase of bulk packing peanuts is right on the money.

A Step by Step Guide to Getting Your Data

For the formula to be useful, you need real numbers from your own operation. It’s easier than it sounds. Just follow these steps:

- Pinpoint Your Go To Box Sizes: Don’t overcomplicate it. List the top 3-5 box sizes your team uses most often. These likely account for the majority of your shipments.

- Calculate the Box Volume: For each of those key box sizes, figure out its volume using the classic Length × Width × Height formula. Then, find the average across your top boxes.

- Estimate Your Average Product Volume: This part can feel tricky, but a good estimate is all you need. Grab a representative sample of the products that go into those common boxes and calculate their average volume.

- Check Your Shipping Volume: Pull up your records. How many packages did you ship last week? Last month? Use that historical data to forecast your "Number of Shipments."

Once you have these four numbers, plug them into the main formula. You'll have a solid estimate of the peanut volume you need to keep on hand.

Don't Forget About Real World Factors

A formula is a great starting point, but the reality on the warehouse floor involves a couple of variables that can throw off a purely mathematical calculation. Smart managers account for these.

- Compression: Packers don't just pour peanuts in; they give them a good shake and press them down to make sure the product is snug. This means you’ll use a bit more material than the raw volume number suggests. A good rule of thumb is to add a 5-10% buffer to your final number to cover this.

- Settling: As packages get bounced around in transit, the peanuts will settle and create small gaps. To prevent this, experienced packers will often overfill the box slightly. This is another great reason to have that small buffer in your inventory calculation.

Building in this buffer isn't about waste; it's about anticipating real world conditions. It ensures you don't get caught short because of how things actually work day to day. Planning for these small details is what keeps your timelines intact and prevents the frustrating delays that come from running out of something as simple as packing peanuts. Securing your supply well in advance means better planning and avoids potential disruptions.

Don't wait for an empty bin to disrupt your workflow. Take control of your supply chain. Request a Quote for your bulk packing peanut needs or Call (800) 326-4403 to talk strategy with our team.

Streamlining Your Warehouse with Smart Storage Solutions

Let’s be honest, managing thousands of cubic feet of packing peanuts can turn your packing stations into a chaotic mess. Piling massive bags in a corner chews up valuable floor space and has your team wasting time moving materials. There's a much smarter way to handle bulk packing peanuts that integrates them right into your workflow, boosting productivity, improving safety, and reducing waste.

The goal is to shift from clumsy, manual handling to a smooth, on demand system. It's not just about cleaning up the workspace; it's about empowering your packing team to work faster and more ergonomically. A proper storage and dispensing solution is a direct investment in your facility's overall throughput.

Reclaiming Floor Space with Overhead Hoppers

One of the most effective ways to get a handle on bulk packing peanuts is with an overhead hopper system. These systems store huge quantities of peanuts in a dispenser mounted near the ceiling. This frees up prime floor space for more critical operations, like pallet staging or adding another packing station.

Hoppers feed peanuts directly down to the packing station through a simple chute or hose. This eliminates all the manual scooping and hauling of heavy bags. With this on demand access, your packers get a constant supply right where they need it, cutting down on wasted movement and increasing packing speed. Getting your void fill organized is just as important as organizing your inventory with efficient bulk rack shelving.

Tips for Managing Bags and Static

Even if you're not ready for a full hopper system, you can still make a huge difference in how your team handles bags of peanuts. Spillage and static cling are the two big culprits that slow things down and create a mess.

To get these common problems under control, try implementing these practices:

- Proper Opening Technique: Don't just rip the bags open. A little training goes a long way. Instruct your staff to cut a small, controlled opening at a bottom corner. This effectively turns the bag into a makeshift funnel, giving them much more control when pouring.

- Static Control: Static electricity is a constant headache with traditional EPS peanuts. You can help manage it by grounding the packing station with anti static mats. Another trick is to use a spray bottle with a 90/10 water to fabric softener solution and lightly mist it into the bin.

- Designated Storage Bins: Instead of having packers work directly from a giant, unwieldy bag, set up large, dedicated bins at each station. This contains the peanuts and makes it much easier for packers to grab what they need.

Special Considerations for Biodegradable Peanuts

If your operation uses biodegradable, starch based peanuts, there’s one extra thing you need to think about with your storage strategy: moisture. Since these peanuts are designed to dissolve in water, you must keep them in a dry environment to ensure they hold up.

Storing biodegradable peanuts in areas with high humidity or potential for water exposure can cause them to clump together or partially dissolve, rendering them ineffective. Ensure they are kept in sealed containers or in a climate controlled part of your warehouse.

By thinking strategically about how you store and dispense your packing peanuts, you can turn a simple supply item into a key part of a highly efficient fulfillment process. Planning for these operational improvements now can prevent major bottlenecks as your shipping volume grows.

How Different Industries Use Packing Peanuts

You might think of packing peanuts as a generic, one size fits all solution, but they are surprisingly specialized. They play a critical role in a ton of industries, well beyond typical online shipments. Seeing how they solve real world problems shows just how flexible this void fill can be. What works for a massive e-commerce warehouse can be tweaked to protect delicate parts for a custom manufacturer.

The demand for reliable protective packaging is only growing. The global market for packing peanuts was valued at around $1.2 billion and is expected to hit $1.95 billion by 2033. That’s a steady compound annual growth rate of 5.7%, driven by smart adoption across these different sectors. You can dig into more data on the packing peanut market's growth.

E-commerce and Retail Fulfillment

In an e-commerce fulfillment center, it's all about speed, cost, and getting it right the first time. These facilities ship a wide variety of products every day—from coffee mugs and books to odd shaped home goods and kitchen gadgets.

Bulk packing peanuts are a perfect match for this fast paced environment. They're incredibly lightweight, which helps keep shipping costs from creeping up. More importantly, they quickly fill the empty space around items that don't fit neatly in a box, making sure everything arrives in one piece and cutting down on costly returns.

Electronics and Technology

Shipping electronics isn't just about preventing bumps and drops. The real enemy is often invisible: electrostatic discharge (ESD). A tiny zap of static electricity can instantly destroy sensitive microchips and turn a pricey piece of equipment into a paperweight.

This is exactly why anti static packing peanuts were invented. These pink tinted peanuts are treated with a special coating that stops static from building up. They offer the same great cushioning as regular peanuts but add a crucial layer of protection for things like:

- Computer parts (motherboards, GPUs)

- Medical diagnostic equipment

- Sensitive laboratory instruments

When you're shipping high value electronics, using anti static peanuts isn't just a good idea—it's essential risk management. That small extra cost is nothing compared to the price of a catastrophic product failure.

Manufacturing and Automotive

For manufacturers and automotive suppliers, the goal is to protect complex, often heavy parts as they move between factories or out to customers. These components can be oddly shaped, with precise tolerances that cannot be compromised.

Packing peanuts are fantastic at locking these items in place inside a box. They prevent parts from shifting, getting scratched, or denting during transit. Whether it’s a custom machined gear, a set of engine parts, or a delicate aerospace component, peanuts mold themselves to any shape, creating a secure cushion against vibrations and impacts.

Healthcare and Medical Supplies

While sterile medical devices require their own specialized packaging, packing peanuts are still vital for shipping a wide range of non sensitive supplies. Think about all the durable medical equipment, administrative supplies, and replacement machine parts that keep a hospital or clinic running.

The lightweight nature of peanuts helps manage shipping budgets, and their protective quality ensures that these essential items are ready to go the moment they arrive. By keeping these goods secure, packing peanuts help maintain the integrity of the entire healthcare supply chain, preventing delays that can have real consequences.

No matter your industry, having a reliable void fill solution is a must. Request a Quote to see our competitive pricing on bulk packing peanuts.

Conclusion: Secure Your Shipping Supplies with Material Handling USA

Knowing which packing material to choose is a great start, but partnering with the right supplier is what keeps your operations running smoothly. Once you’ve figured out how to select, calculate, and manage your bulk packing peanuts, the next step is putting that knowledge into practice. At Material Handling USA, we are dedicated to making that process seamless.

For warehouse managers and buyers, consistency is everything. That’s why we’re committed to providing high quality products that don't just protect your goods—they protect your company's reputation. Our goal isn't just to be another vendor; we aim to be a dependable partner in your success.

A Partnership Built on Speed and Quality

In logistics, timing is everything. A delay in receiving essential supplies like packing peanuts can create a bottleneck, grinding your fulfillment process to a halt. We tackle this by offering the fastest shipping and delivery in the industry. This helps keep your warehouse stocked and your shipping lines moving, even when demand spikes.

Securing your supply chain today means you can sidestep tomorrow's disruptions and ensure your team always has what it needs. This proactive approach is the hallmark of an efficient, resilient operation. By planning ahead, you build the stability your facility needs to meet deadlines and keep customers happy. For a bigger picture view, check out our resources on wholesale shipping supplies.

Understanding the Market and Your Needs

The global demand for protective packaging is always shifting. The packaging peanuts market, for example, shows significant regional variation. India is forecasted to see a CAGR of 5.50%, while the more mature United States market is projected at a more modest 1.40% CAGR. You can discover more insights about these packaging peanut market trends to get a better handle on the landscape.

By partnering with an established supplier like Material Handling USA, you gain access to competitive pricing and a stable supply, regardless of market fluctuations. We help you stay ahead of supply chain challenges.

Our team is here to help you find the best solution for your facility’s unique needs. We even offer free quotes and no obligation layout and design services to help you optimize your packing stations and storage areas.

Your Next Step to a Stronger Supply Chain

A reliable partnership doesn’t just simplify procurement—it strengthens your entire fulfillment process. Don't wait for a supply shortage to expose a weak link in your operations. Get in touch with our specialists today to talk about your bulk packing peanut needs and see how our industry leading service can benefit your business.

Ready to secure your supplies and improve your workflow? Request a Quote online or Call (800) 326-4403 to speak directly with one of our experts.

Frequently Asked Questions About Bulk Packing Peanuts

When it comes to sourcing and using bulk packing peanuts, we get a lot of the same questions from facility managers and buyers. Getting straight answers helps you make the right call for your operation and your budget. Here’s a quick rundown of what people usually ask.

Are Biodegradable and Traditional Peanuts Interchangeable?

While they both work as void fill, you can't always swap one for the other. Biodegradable peanuts, made from plant starch, are perfect for lighter items and are naturally anti static. But keep in mind, they don't do well with moisture, which is a big deal if your packages are traveling long distances or sitting in a humid warehouse. Traditional EPS peanuts are much tougher and completely moisture resistant, making them the go to choice for heavy, fragile, or high value items.

How Should I Dispose of Packing Peanuts?

Disposal depends on the type.

- Biodegradable Peanuts: These are made for easy, eco friendly disposal. They dissolve in water, so you can wash them down a sink. You can also toss them into a compost pile.

- Traditional EPS Peanuts: These don't break down, so don't put them in the recycling bin. The best option is reuse. Many local shipping stores are happy to take clean packing peanuts. If not, bag them up and put them in the regular trash.

Quick Tip: Not sure which is which? Drop one in a glass of water. A biodegradable peanut will start dissolving. An EPS peanut will float.

Is There a Weight Limit for Boxes Filled with Peanuts?

The peanuts themselves are feather light, but the boxes you put them in have weight limits. Most trash services have rules about how heavy carts can be—for example, a standard disposal cart often cannot be heavier than 200 lbs. Always check with your local waste management company for their specific rules. More importantly, when shipping, you must follow the weight limits set by your carrier, like UPS or FedEx, and ensure your box is rated for the total weight.

Can Anti Static Peanuts Be Used for All Products?

You can use anti static peanuts for anything, but they are specifically designed for shipping sensitive electronics. They have a coating that stops electrostatic discharge (ESD) from building up, which can destroy components like microprocessors and circuit boards. Using them for non electronic items is not cost effective. It's best to reserve anti static peanuts for when ESD protection is essential. To see what other essential materials you should have on hand, check out our guide to frequently purchased shipping and packing supplies.

At Material Handling USA, we provide the high quality supplies you need with the industry leading speed you demand. Secure your supply chain and keep your operations running smoothly.

Request a Quote or call our specialists at (800) 326-4403 to discuss your void fill needs.