For any facility manager or buyer, the bottom line is everything. When you stack them up against traditional construction, the primary benefits of modular buildings are crystal clear: significant cost savings of up to 50%, drastically faster project timelines, and far superior quality control.

How is this possible? It’s simple. We move the majority of the build process off your busy site and into a controlled factory setting. This shift minimizes waste, trims labor hours, and eliminates the costly on-site delays that can kill a project budget.

The Financial Advantage: How Modular Buildings Reduce Costs

When you're researching a new construction project, the financial piece is always front and center. Modular buildings make a compelling financial case, directly impacting your budget and the overall return on your investment. The entire process is fundamentally more efficient, and those efficiencies translate directly into savings.

Think of it like an automotive assembly line versus building a car from scratch in an open field. The level of control, precision, and predictability you get from a factory environment is simply unmatched.

This efficiency comes from constructing every component off-site. The controlled environment removes all the variables that bloat traditional stick-built project budgets, such as weather delays, on-site material theft, and inconsistent labor productivity. By standardizing the process, we can optimize every single step.

Driving Down Material and Labor Expenses

A huge chunk of the cost savings comes from smarter material management. In our factory, we buy materials in bulk, securing better pricing that we can then pass on to you. Plus, precision cutting and assembly mean we drastically reduce material waste, which is one of the most common sources of budget overruns in conventional construction.

Labor costs also become much more predictable. A dedicated, skilled team working in a controlled setting is always more efficient than trying to coordinate a dozen different subcontractors on a chaotic job site. This leads to fewer billable hours and avoids the premium you pay for overtime just to catch up from delays.

Accelerating Your Return on Investment

One of the most powerful financial benefits of modular buildings is the sheer speed of deployment. While your site is being prepped, your building is being manufactured at the same time. This parallel workflow can slash project timelines by as much as half.

A faster construction schedule means your new warehouse office, cleanroom, or secure enclosure becomes operational that much sooner. This accelerates your return on investment, allowing you to start generating revenue or improving operational efficiency weeks or even months ahead of a traditional build.

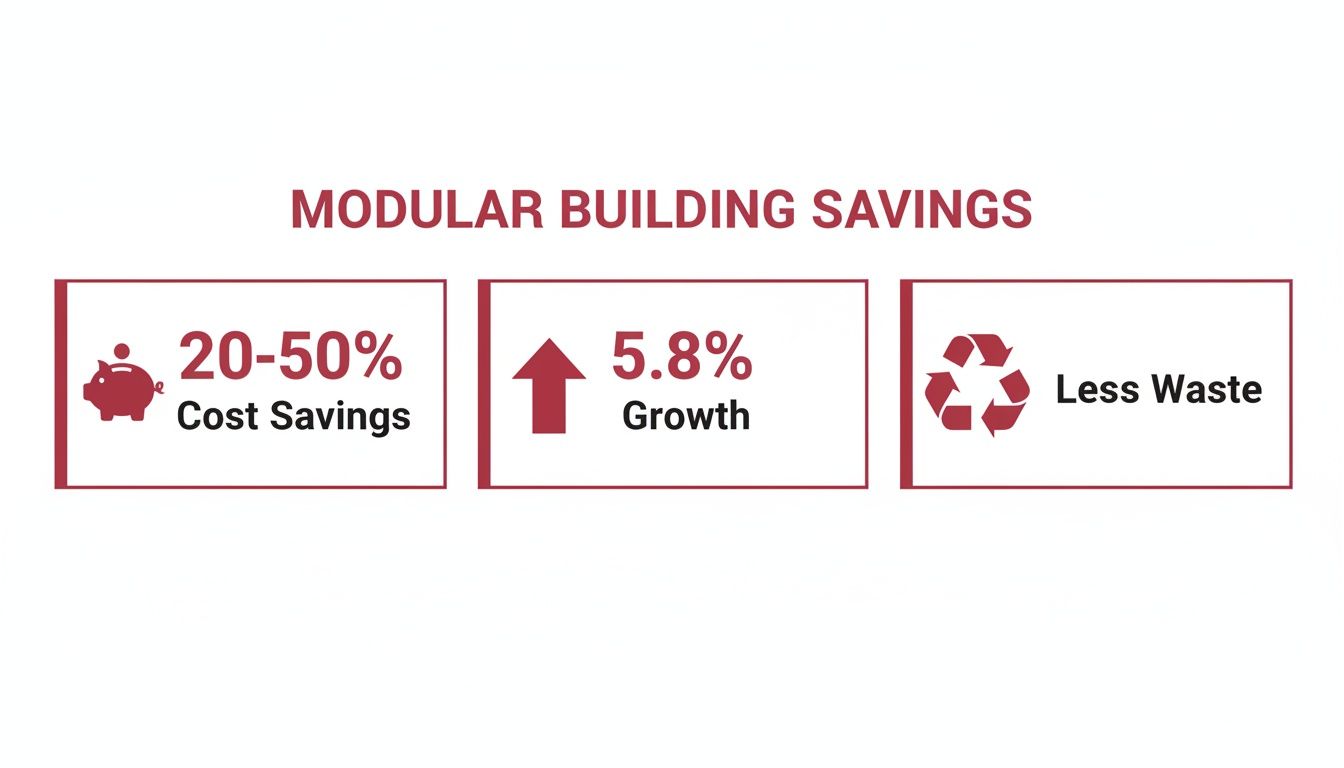

This infographic breaks down the core savings you can expect.

The numbers don't lie. Modular construction directly leads to substantial cost reductions, a smaller environmental footprint, and aligns with a rapidly growing market trend.

A quick look at the numbers shows where the real savings are. While traditional construction is plagued by variable costs, modular building offers much more certainty.

Modular vs Traditional Construction Cost Breakdown

| Cost Factor | Modular Buildings | Traditional Construction |

|---|---|---|

| Labor | Controlled, factory-based wages; fewer hours | Variable on-site rates; prone to overtime |

| Materials | Bulk purchasing discounts; minimal waste | Subject to market fluctuations; higher waste |

| Timeline | 30-50% faster; parallel site prep/build | Sequential; highly susceptible to delays |

| Weather Delays | Negligible; indoor factory construction | Significant risk, causing schedule overruns |

| Change Orders | Minimal; design locked in pre-fabrication | Common and costly during the build process |

| Site Disruption | Minimal; components delivered for assembly | High; constant traffic, noise, and clutter |

This comparison makes it clear: the modular process is engineered from the ground up for financial efficiency and predictability.

Gaining Budgetary Certainty from the Start

Traditional construction projects are notorious for surprise costs and endless change orders. The modular process, on the other hand, gives you much greater cost certainty right from the get-go. With designs finalized and materials secured early, the initial quote you receive is a far more reliable reflection of the final price.

For anyone who has had to manage a project budget, that predictability is priceless.

The data backs this up. Modular buildings often slash overall project expenses by 20-50%. For a warehouse operations manager, this means a much quicker ROI on essential expansions like a new in-plant office or a secure modular enclosure. It's no surprise the U.S. non-residential prefab market is projected to hit $108.36 billion by 2030 because this efficiency is what's driving the growth.

Making a smart financial decision means weighing all the factors. For developers and facility managers looking to significantly reduce construction costs, modular buildings offer a proven, practical, and effective solution. The combination of reduced labor, minimized waste, and a faster timeline makes it a financially sound choice for any expanding facility.

Ready to see how much you could save? We provide free layouts and designs with no obligation.

Call (800) 326-4403 or Request a Quote today to get started.

Accelerating Your Timeline with Efficient Modular Construction

In today's competitive landscape, speed is not just a perk, it is a powerful strategic advantage. One of the biggest wins with modular buildings is the dramatic reduction in project timelines, thanks to a parallel construction process that traditional methods just cannot touch.

Think about it this way: while your on-site crew is busy preparing the foundation, running utilities, and handling all the groundwork, your building's modules are already being precision-built in our controlled factory environment. This simultaneous workflow is the secret to cutting project schedules by as much as half.

This speed means far less disruption to your daily operations, which is a massive relief for any busy facility. Instead of dealing with months of on-site noise, traffic, and safety cones, you get a clean, streamlined installation that is over in a fraction of the time.

From Months to Weeks

Imagine getting a new in-plant office, guard booth, or employee break room up and running in a matter of weeks, not months. The off-site model sidesteps the usual suspects that plague traditional builds like bad weather, subcontractor no-shows, and material delays. Everything is built indoors, to exacting standards, on a schedule you can actually count on.

By completing projects 50-70% faster than stick-built methods, modular construction provides a critical operational advantage. With up to 90% of the work happening in controlled factories, on-site timelines are slashed from months to mere weeks.

This speed is a game changer for facility teams needing to expand quickly, whether it is adding mezzanines or secure server cages. It’s no surprise the U.S. modular market hit $20.3 billion in 2024 and is projected to reach $25.4 billion by 2029, growing faster than the rest of the construction industry. You can discover more market insights on GlobeNewswire.

Locking in Predictability and Avoiding Delays

A faster timeline brings another huge benefit: cost stability. By finalizing designs and starting fabrication early, you can lock in current material prices and sidestep the market volatility that can blow up budgets on long-term projects. You also avoid the seasonal rush that often causes labor shortages and delays in traditional building.

This approach gives you a level of schedule certainty that is priceless for business planning. Knowing exactly when your new space will be ready allows for better resource allocation, smoother operational transitions, and more accurate forecasting. Many of our clients find that planning their projects well before their busy season results in even quicker installations.

To really see the difference, here is a quick comparison of the two processes.

Modular vs. Traditional Construction Timeline

| Project Stage | Modular Construction | Traditional Construction |

|---|---|---|

| Site Preparation | Happens at the same time as off-site fabrication. | Must be 100% complete before building starts. |

| Building Fabrication | Done in a controlled factory, immune to weather. | Sequential, on-site, exposed to elements and delays. |

| On-Site Assembly | Modules are delivered and assembled in days. | Takes weeks or months to frame and finish. |

| Interior Finishing | Mostly completed off-site for consistent quality. | Done on-site, subject to delays and rework. |

| Total Duration | 4-12 Weeks | 4-9+ Months |

This side-by-side view makes it clear how the modular process eliminates wasted time by overlapping key project stages. It is a core reason why more managers are choosing modular for their facility needs. You can learn more about how our solutions offer fast, code-compliant construction in our detailed guide.

Choosing an efficient construction method is one of the smartest decisions you can make for your facility. With the fastest shipping and delivery in the industry, we can help you get your project off the ground and completed on a timeline that supports your business goals.

Ready to accelerate your next project? Get a free, no-obligation quote and layout design to see how quickly we can deliver the space you need.

Contact Us or call us at (800) 326-4403 to discuss your project today.

Future-Proofing Your Operations with Flexible and Scalable Designs

Your business is not static, so why should your facility be? One of the biggest advantages of modular buildings is their built-in adaptability. In a world where your operational needs can pivot on a dime, being locked into a rigid, permanent footprint is a serious liability. Modular construction offers a much smarter, more dynamic path forward.

The secret is baked right into the design. Modular components are engineered from the ground up for flexibility, letting you easily reconfigure, expand, or even pick up and move entire structures as your business evolves. This is not just about tacking on more space; it is about turning your facility into a responsive asset that grows right alongside you.

This long-term strategic value keeps you from getting trapped by yesterday's decisions, offering a sustainable and cost-effective way to manage your growth.

Adapting to Evolving Business Needs

Think about it. Your production line suddenly needs a new quality control lab, or a hiring surge means you need more office space, fast. With traditional construction, you would be looking at a major, disruptive overhaul filled with demolition, dust, and downtime.

With a modular system, the process is clean and surprisingly simple. New modules can be seamlessly added to an existing structure, often with very little interruption to your daily operations. This "plug-and-play" capability means you can scale up your facility in precise steps, only paying for the space you need, exactly when you need it.

Design Freedom for Facility Planners

For facility planners and managers, this flexibility is a game-changer. You are no longer forced to make decade-long predictions about your space requirements. Instead, you can design for today while building in the capacity to adapt for whatever comes next.

This approach gives you the power to:

- Reconfigure Layouts: Easily change interior walls to create new offices, conference rooms, or specialized work zones without the headache of major construction.

- Expand Horizontally or Vertically: Add new modules to increase your footprint or, where it makes sense structurally, stack units to build upward and make the most of your property.

- Relocate and Reuse: If your company moves to a new site or your needs completely change, many modular structures can be disassembled and reassembled somewhere else, protecting your initial investment.

The ability to adapt is not just a convenience; it is a real competitive advantage. Modular design allows you to respond to market opportunities or internal changes with agility, avoiding the huge costs and operational paralysis that come with traditional renovation.

By planning your facility's evolution from day one, you ensure your infrastructure supports, rather than hinders, your company's growth. The demand for adaptable spaces is a key reason so many managers now prioritize modular solutions in their long-term planning. You can dive deeper into these adaptable systems in our guide to relocatable and flexible modular solutions.

Scaling Operations Without the Disruption

The process of scaling is where modular really shines. Instead of shutting down parts of your facility for months, the on-site assembly for a modular expansion can often be done in just a few days. Since the vast majority of the construction happens off-site, the noise, mess, and safety hazards are kept far away from your active work areas.

This minimized disruption protects your team's productivity and ensures a safer environment for everyone. It is a forward-thinking approach that recognizes your facility needs to grow, but that growth should not come at the expense of your current operations.

If you are planning for future growth, our team can help you design a scalable solution from the start. We provide free layouts and designs with no obligation, showing you exactly how a modular system can adapt to your future needs.

Contact Us or call (800) 326-4403 for a free consultation.

Enhancing Safety and Sustainability on Your Next Project

In today's world, a well-run business is measured by more than just its bottom line. Your commitment to safety and environmental responsibility speaks volumes. Choosing modular construction is a clear, powerful way to demonstrate that commitment, all while making your entire operation more resilient.

The magic happens by moving the bulk of the construction process off your property and into a controlled factory setting. By fabricating up to 90% of the structure off-site, we dramatically reduce the common hazards you see with traditional construction projects. Think about it: less truck traffic, less noise pollution, and a massive drop in the risk of on-site accidents.

This cleaner, safer process means fewer disruptions to your daily operations and a much better environment for your team. For managers tasked with hitting specific ESG goals or compliance mandates, modular is not just an option, it is a practical solution.

A Greener Approach to Building

From a sustainability standpoint, the case for modular is just as strong. The precision manufacturing that happens in a factory slashes material waste. Unlike a typical job site where materials are often over-ordered and cut on the fly, our process optimizes every single resource. The result is a drastic reduction in what ends up in a landfill.

This controlled environment also makes it much easier to integrate energy-efficient systems and materials right from the start. It is a lot simpler to guarantee perfect insulation, airtight seals, and high-performance windows when every piece is assembled under strict quality controls.

Modular buildings are a standout for sustainability, often slashing material waste by 70-90% and cutting energy consumption by 30-50%. This eco-friendly approach is a huge reason the global modular market is set to grow from $111.07 billion in 2025 to $207.82 billion by 2033.

This factory-first method is at the heart of building smarter, more responsible facilities. You can learn more about our energy efficient modular buildings in our detailed article on the topic.

Prioritizing a Safer Work Environment

Safety on a busy industrial site is absolutely non-negotiable. Traditional construction brings a whole host of risks: heavy machinery, constant deliveries, and crews of subcontractors you do not know. By shifting nearly all of this activity to our factory, we reduce your on-site liability and help you maintain a secure, predictable operational environment.

This is a major factor driving companies toward modular. With construction-related incidents being a constant concern, off-site methods that limit worker exposure are quickly becoming the go-to for safety-conscious organizations. A factory provides a stable, controlled setting where safety protocols can be rigorously enforced, far from the chaos of an active job site.

To put it all in perspective, here is a clear look at how modular construction stacks up against traditional methods on the benchmarks that matter most.

Sustainability and Safety Checklist for Building Projects

For managers evaluating their next project, this checklist highlights how modular construction directly addresses key safety and sustainability concerns compared to conventional methods.

| Benchmark | Modular Buildings | Traditional Construction |

|---|---|---|

| On-Site Accidents | Significantly lower risk due to minimal on-site activity. | Higher risk with multiple crews and heavy machinery. |

| Material Waste | Minimal; precision cutting reduces waste by up to 90%. | High; often 10-15% of materials are wasted. |

| Air & Noise Pollution | Minimal on-site disruption, keeping operations quiet. | Significant noise, dust, and emissions for months. |

| Energy Efficiency | High; factory setting allows for better quality control. | Variable; dependent on on-site workmanship and conditions. |

| Site Security | Less risk of theft or vandalism with fewer materials stored on-site. | Materials and equipment are vulnerable on an open site. |

This checklist makes it obvious why managers focused on operational excellence and corporate responsibility see modular as the superior path forward.

Choosing a building method is about more than just getting the square footage you need; it is about aligning your facility with your company’s core values. With a documented reduction in waste and a safer, more controlled building process, modular construction offers a tangible way to hit your sustainability and safety targets.

Ready to build a safer, greener facility? Our team offers free layouts and designs to show you exactly how a modular solution can meet both your operational and ESG objectives.

Request a Quote or call (800) 326-4403 to speak with an expert.

Partnering with Material Handling USA for Your Modular Project

Understanding how a modular building can solve your space challenges is a great first step. But the most important decision you will make is choosing the right team to build it. This is where we come in. At Material Handling USA, we are not just selling you a building; we are providing a complete, start-to-finish partnership laser-focused on your success.

We have built our entire approach on a simple foundation of trust, expertise, and delivering real-world results. We know managers and buyers need a solution that works, one that is easy to plan, procure, and install. From the first sketch to the final walkthrough, our team is here to make the process seamless.

We have earned our reputation by focusing on what truly matters to our clients. When you work with us, you are not just getting a vendor; you are getting a team of experienced problem-solvers who will guide you every step of the way.

Our Core Commitments to You

Choosing a partner is about much more than a price tag. It is about finding a team that gets your goals and has the proven ability to deliver on your specific operational needs. We have built our service around a few key commitments that directly impact your project's bottom line and timeline.

These are not just promises we make; they are the principles we operate by every single day.

- Competitive Pricing: We use our long-standing industry relationships and streamlined processes to offer some of the most competitive pricing you will find. It is all about getting you the absolute maximum value for your investment.

- The Industry's Fastest Shipping and Delivery: In this business, speed is everything. Our logistics network is finely tuned to provide the fastest shipping and delivery in the industry, getting your building on-site and operational on an aggressive timeline.

- A Dedication to Quality Materials: A building is only as good as what it is made of. We are absolutely uncompromising when it comes to using high-quality, durable materials built to handle the rigors of any industrial environment.

These core tenets are how we set every single project up for success right from the start.

Your Vision Realized, With No Obligation

One of the biggest roadblocks to starting any project is just picturing the final result and knowing what it will actually cost. We eliminate that guesswork entirely by offering free, no-obligation layouts and design consultations. Our expert team sits down with you to map out a detailed plan that fits your workflow perfectly, all before you spend a dime.

This collaborative design process is the heart of our partnership approach. It ensures the final product is not just a generic building, but a custom-designed asset that enhances your workflow, boosts efficiency, and meets your goals for years to come.

By providing this upfront service for free, we empower you to make a fully informed decision with total confidence. We have seen a big increase in demand for our design services, which tells us that starting the conversation early is the best way to secure a spot in our production schedule and avoid seasonal backlogs.

Our process is refreshingly simple. We listen to your needs, draw up a custom layout, and give you a clear, detailed quote. This way, you see the full picture and know exactly how our modular solution will fit into your facility.

If you are ready to see what a modular building can do for your facility, the next step is easy. Let our team show you what is possible with a complimentary design and quote.

Request a Quote or call (800) 326-4403 to start your free design consultation today.

Common Questions About Modular Buildings, Answered

Thinking about adding a new building to your facility? It is a big decision, and it is only natural to have questions. The concept of building a structure off-site and then bringing it in for final assembly is a bit different from what most people are used to with traditional construction.

To help clear things up, we have put together some straightforward answers to the questions we hear most often from facility managers and buyers. Our goal here is to give you the clarity and confidence you need to figure out what is best for your operation.

Are Modular Buildings as Tough as Traditional Buildings?

Absolutely. This is probably the biggest myth we have to bust. Our modular buildings are engineered to meet, and often exceed, the exact same building codes and standards that apply to conventional, site-built structures. We build them with high-quality steel frames and materials specifically chosen for demanding industrial environments.

Because the construction happens in a controlled factory setting, every single weld, joint, and component is inspected under strict quality control. This precision process actually results in a building that is often more structurally sound and consistent. Plus, each module has to be tough enough to withstand the stress of transport, which makes them exceptionally robust by the time they arrive at your site.

What Are My Options for Customization?

This is where modular really shines. You are not stuck picking from a handful of cookie-cutter layouts. The design flexibility is one of the most powerful advantages, and we work right alongside you to create a space that fits your workflow like a glove.

You have got control over a whole range of features, including things like:

- Dimensions and Layout: Need a specific size, room configuration, or door and window placement? No problem. We can design the layout to optimize your exact process.

- Electrical and HVAC: We will integrate whatever you need, from specialized electrical systems and data ports for a server room to the right climate control for a comfortable break room.

- Finishes Inside and Out: You can choose from a variety of siding materials, flooring options, wall coverings, and paint colors to match your company's brand or the look of your existing buildings.

- Specialty Features: We can easily incorporate things like reinforced flooring for heavy machinery, soundproofing for quiet office spaces, or specific types of window glazing for enhanced security.

How Long Does the On-Site Installation Actually Take?

The on-site part of the process is incredibly fast. Since up to 90% of the construction is already done in our factory, the time we spend at your facility is kept to a bare minimum. Once your site is prepped and the foundation is ready, the modules are delivered.

Setting the modules and assembling the core structure usually takes just a few days. The final "button-up" work, like connecting utilities and finishing interior seams, is also completed very quickly. This dramatically cuts down on the on-site disruption, noise, and safety headaches that come with a months-long traditional construction project.

Do I Still Need a Permit for a Modular Building?

Yes, in most cases, you will need a permit, just like you would for any other permanent or semi-permanent structure. Modular buildings are designed from the ground up to comply with all relevant state and local building codes, including International Building Code (IBC) standards.

The good news is that the permitting process is often much more straightforward. The building plans are typically pre-approved at the state level where the factory is located, so your local officials can focus mainly on the site plan, foundation, and utility connections. We are here to provide guidance and all the necessary documentation to help make this step as smooth as possible for you.

Get Started on Your Modular Project Today

Choosing a modular building means faster timelines, significant cost savings, and a flexible, high-quality space built for your exact needs. By moving construction into a controlled factory, you gain budget certainty and minimize disruption to your operations, allowing your business to expand efficiently and sustainably. With demand for faster, more predictable construction solutions growing, getting your project planned early ensures you can take advantage of these benefits sooner rather than later.

At Material Handling USA, we provide competitive pricing, the industry's fastest delivery, and free, no-obligation design consultations to make your vision a reality. Let our experts show you how a modular solution can be the smartest investment for your facility's future.

Request a Quote or call (800) 326-4403 to talk about how a modular building can directly benefit your operations.