For facility managers, buyers, and anyone looking for a smarter alternative to traditional construction, the most significant benefits of modular construction are speed, cost certainty, and predictable quality. It’s a simple but powerful shift: we move the bulk of the building process off your busy site and into a controlled factory setting. This approach solves the classic problems of blown budgets and unpredictable timelines right from the start.

Understanding The Core Advantages Of Modular Construction

Modular construction isn't just a slightly different way to build; it's a fundamentally more efficient process.

Think of it this way: traditional construction is like building a car from scratch in your driveway, exposed to weather and unforeseen delays. Modular is like assembling that same car on a modern, high-tech production line. We build standardized sections, or "modules," in a factory while the foundational work happens simultaneously at your facility.

This parallel workflow is the key. Instead of the old, linear "wait then build" method, we do both at the same time. This simple change collapses project timelines and gets your facility operational faster than you thought possible.

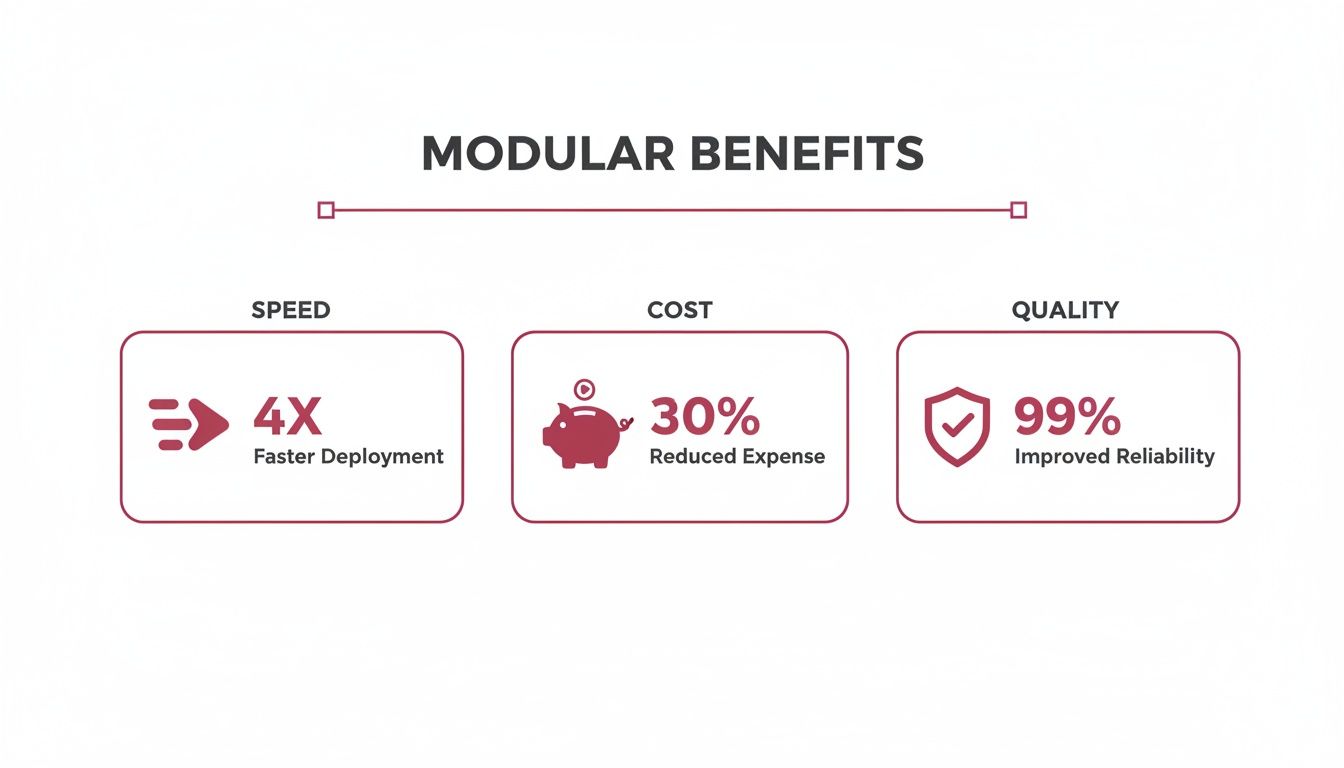

Speed, Cost, and Quality: The Big Three

For any facility manager or procurement lead, the advantages boil down to three critical areas that directly impact your bottom line and operational readiness.

- Dramatically Faster Timelines: By overlapping off-site fabrication with on-site prep work, projects can be completed up to 50% faster than with traditional methods. That means your new office, cleanroom, or warehouse is up and running—adding value to your business—in a fraction of the time.

- Rock-Solid Budget Certainty: Factory production eliminates the costly surprises that derail budgets. We lock in labor costs, slash material waste, and remove weather delays from the equation. The result? You get a firm, reliable price right from the start. No guesswork.

- Superior Quality Control: Every module is built to exacting standards under strict, indoor quality checks. This factory environment allows for a level of precision and durability that's incredibly difficult to achieve on a dynamic, active construction site.

To get a clearer picture, this table breaks down the key differences between the two approaches.

Modular Construction vs Traditional Construction at a Glance

| Factor | Modular Construction | Traditional On-Site Construction |

|---|---|---|

| Project Timeline | Up to 50% faster due to parallel workflows | Linear process; slower and sequential |

| Cost | Fixed pricing, reduced waste, predictable labor | Prone to overruns from delays and unforeseen issues |

| Quality | Consistent, high-quality builds in a controlled factory | Quality can vary with site conditions and teams |

| Site Disruption | Minimal; most work is done off-site | Significant; ongoing noise, mess, and safety risks |

| Weather Impact | Virtually none; fabrication is indoors | Major source of delays and increased costs |

| Waste | Significantly less material waste | Higher waste due to on-site cutting and errors |

This side-by-side comparison makes it clear why more operations are turning to modular.

These three pillars—speed, cost, and quality—create a building solution that’s not just faster but also far more dependable and financially predictable. When project deadlines are tight and you need a fixed cost you can count on, modular construction makes planning and execution significantly smoother.

Ready to see how this approach can be applied to your specific needs? Learn more about our modular buildings and discover the perfect fit for your facility.

Build Faster and Get Operational Sooner

In any business, time is money. Project delays mean lost productivity, deferred revenue, and disrupted operations. One of the most impactful benefits of modular construction is its power to radically shorten project timelines, getting your new space functional and contributing to your bottom line weeks or even months ahead of schedule.

The secret behind this speed is a simple but powerful concept: parallel processing.

Think about a traditional construction project. Everything happens in a straight line, one step after another. First, you prepare the site. Then, you lay the foundation. Only after that’s done can you start framing the structure. Each step must wait for the one before it to finish, creating a long, sequential timeline that's vulnerable to countless delays.

Modular construction flips this old model on its head.

The Power of Parallel Workflows

Instead of a linear process, critical tasks get done at the same time. While your team is on-site handling prep work—like grading the land and pouring the foundation—we're already building the modules for your new structure in our factory. This simple shift is a complete game-changer.

Imagine building a car on an efficient assembly line versus building it piece by piece in your driveway during a rainstorm. The factory approach is faster, more precise, and isn't affected by things you can't control. That’s the advantage modular brings to your project. Up to 90% of the construction is completed off-site in a controlled environment.

This method completely sidesteps the most common and costly delays that plague traditional construction:

- Weather Delays: Rain, snow, and extreme heat can bring a conventional job site to a halt for days or even weeks. Our indoor fabrication process keeps moving forward, no matter what the weather is doing outside.

- Labor Shortages: We have a consistent, skilled workforce in our factory. This helps us avoid the on-site labor challenges that can slow down traditional projects and drive up costs.

- Material and Supply Chain Issues: We order materials in bulk and keep them securely stored at our facility. This minimizes the risk of supply chain disruptions that can sideline a conventional build for weeks on end.

By taking these variables out of the equation, modular construction turns a project timeline from an unpredictable estimate into a reliable schedule. For any manager who needs to get a new production line, warehouse office, or cleanroom up and running, that predictability is invaluable for planning and forecasting.

Realizing a Faster Return on Investment

Whether you're a warehouse manager needing a new shipping office or a lab administrator expanding a critical research space, this speed translates directly into a faster return on your investment. The sooner your new facility is operational, the sooner it starts generating value for your organization.

Industry analysis backs this up. Reports consistently show that modular projects wrap up 30% to 50% faster than their traditional counterparts. This is a direct result of efficient off-site prefabrication happening under ideal conditions.

The speed advantage also means far less disruption to your daily operations. With most of the construction happening somewhere else, you avoid months of on-site noise, traffic, and safety hazards. The modules arrive nearly complete and are assembled in a fraction of the time, letting your business run smoothly.

For businesses where project timelines are everything, our approach to commercial modular buildings offers fast, code-compliant construction designed to get you operational sooner. Because project slots can fill up based on material availability and our production schedule, starting the conversation early is the best way to secure a timeline that meets your goals.

Gain Budget Certainty and Significant Cost Savings

For any manager, the budget is critical. One of the most powerful arguments for modular construction is the financial certainty it provides. We’re not just talking about potential savings; we're talking about turning a financial estimate into a predictable, solid investment.

Think about the last traditional construction project you oversaw. Unexpected costs are practically part of the process. Bad weather, a sudden labor shortage, or a spike in material prices can throw an entire financial plan into chaos. Because we complete the vast majority of the work in a controlled factory setting, we can provide a firm, accurate price right from the start. Your budget is shielded from those variables.

Where Do the Savings Come From?

The financial upside isn't just one big discount. It’s the natural result of a smarter, more efficient process that reduces costs across several key areas of your project.

- Reduced On-Site Labor: With up to 90% of the construction happening off-site in our facility, you drastically cut down the hours needed for expensive and less predictable on-site labor.

- Minimized Material Waste: In the factory, materials are cut and assembled with computer-aided precision. This slashes the kind of waste that’s common on a traditional job site. Less waste directly translates to lower material costs.

- Fewer Costly Delays: As mentioned, avoiding weather delays and site coordination issues doesn't just save time—it saves a serious amount of money on crew and equipment costs.

For manufacturing plant maintenance teams, government agencies, and healthcare administrators working with tight budgets, this model is a game-changer. Locking in a fixed project cost early helps sidestep the impacts of a volatile market.

For any organization that needs financial predictability, the modular approach is a clear winner. You can plan your capital expenditures with confidence, knowing the price you’re quoted is the price you’ll pay. This is a critical advantage for long-term financial planning and securing internal project approvals.

The Financial Impact of Efficiency

When you add up all these efficiencies, the numbers are compelling. Industry research consistently shows that modular construction can deliver total project cost savings of up to 20%. These aren't just theoretical figures; they come from real-world productivity gains, optimized labor, and far fewer budget overruns.

If you want to dive deeper into the market trends, you can explore the full research about modular construction growth.

Cost Breakdown: Modular vs. Traditional Projects

To really see where the savings kick in, this table breaks down how modular construction turns traditional budget risks into predictable costs. It’s a clear illustration of where that budget certainty comes from.

| Cost Category | Modular Construction Impact | Traditional Construction Challenge |

|---|---|---|

| Labor Costs | Controlled, predictable factory labor rates. | Variable on-site rates and overtime risk. |

| Material Costs | Reduced waste and bulk purchasing savings. | Higher waste from on-site cutting and errors. |

| Timeline Costs | Fewer delays mean lower carrying costs. | Delays lead to extended equipment rental and overhead. |

| Change Orders | Design is finalized early, minimizing changes. | On-site changes are common and expensive. |

| Contingency Budget | Smaller contingency needed due to fewer risks. | Larger contingency required for unforeseen issues. |

The evidence is clear: the financial benefits are a core advantage of going modular. By choosing a more controlled and efficient process, you aren't just putting up a new building; you're making a smart, predictable investment.

Ready to see how these savings could apply to your project? Request a Quote from our team today for a free, no-obligation estimate and a custom layout.

Improve Quality Control and Workplace Safety

For any facility manager, quality and safety are non-negotiable. They are the bedrock of a successful operation. One of the standout benefits of modular construction is how it inherently elevates both—not as an afterthought, but as a direct result of moving the build process into a controlled, factory setting.

Think of it like a high-tech manufacturing line rather than a traditional construction site. Inside our facility, every component is built with precision and subjected to rigorous quality checks at each step. This controlled environment shields materials from weather damage and eliminates the variables you’d find on a busy, unpredictable job site.

The result is a building with tighter seals, more precise fits, and far greater durability. Whether it's a simple guard shack or a complex, multi-room cleanroom, this factory-first approach locks in a higher standard of quality from the very beginning.

A Safer Process from Start to Finish

Beyond the quality of the building, moving up to 90% of construction activity off-site is a game-changer for workplace safety. Traditional construction sites are inherently dynamic. The constant movement of heavy equipment, materials, and personnel creates a field of potential hazards.

By fabricating modules in our factory, we slash those on-site risks for both your employees and our installation teams. It’s a cleaner, more predictable process that leads to significant safety improvements:

- Less Site Congestion: Fewer trucks, workers, and material piles mean the work area is organized, easier to navigate, and fundamentally safer.

- Reduced Fall Hazards: Most of the work happens at ground level in our factory, drastically minimizing the risks of working at heights that are common in conventional builds.

- Controlled Environment: Our factory floor has set safety protocols, consistent lighting, and stable surfaces, removing many of the environmental dangers of an open-air job site.

For any manager responsible for site safety and OSHA compliance, this reduction in on-site risk is a critical benefit. It simplifies safety management, reduces the potential for accidents, and creates a more secure environment for everyone involved in the project.

The Link Between Quality and Safety

In modular construction, better quality control and enhanced safety are two sides of the same coin. A process built around precision and order naturally creates a safer environment to work in.

This disciplined approach is particularly valuable for facilities with specialized needs, like laboratories or secure storage areas, where the building's integrity is mission-critical. The meticulous assembly process in our factory ensures every wall, joint, and fixture meets exact specifications—a level of detail that's tough to achieve on a conventional job site battling weather and subcontractor schedules.

The factory gives us the ideal conditions to build it right the first time, every time.

Given the current demand for industrial space, securing a spot in our production schedule ensures you not only get a higher-quality building but can also plan your safety and installation timeline with confidence. Contact Us to discuss your project and get a free, no-obligation layout design.

Support Sustainability and Reduce Environmental Impact

For companies serious about corporate responsibility, the smaller environmental footprint of modular construction isn't just a bonus—it's a core advantage. The factory-based building process is less wasteful than traditional on-site construction, offering a direct path for businesses aiming to meet their sustainability targets.

The precision of factory fabrication drastically cuts down on material waste. Instead of materials being cut and fitted on an open job site—where a bad measurement or a sudden storm can create a pile of scrap—our process optimizes every piece of steel and drywall. This efficiency doesn't just lower project costs; it means far less debris ends up in a landfill.

On top of that, a modular project naturally has a smaller carbon footprint. With the bulk of the work happening in one central location, you eliminate countless vehicle trips for material deliveries and worker commutes, slashing overall emissions.

Promoting a Circular Economy

The biggest environmental win might be how modular buildings embrace the circular economy. Unlike old-school structures that get demolished and hauled away, modular components are designed from the ground up for disassembly and reuse. This lets you reconfigure, relocate, or even expand your space with almost no new material and virtually zero waste.

This flexibility is a massive asset for any dynamic business. It means your facilities can adapt as your needs change, future-proofing your investment while proving your commitment to sustainable practices.

By its very nature, modular is a lean construction method. It reduces waste, minimizes site disruption, and creates adaptable structures that serve your business for years to come. This aligns perfectly with modern corporate goals for efficiency and environmental stewardship.

Tangible Environmental Benefits

The green benefits of modular are well-documented. This method excels at cutting waste and emissions, making it an obvious choice for eco-conscious operations. These advantages are part of a larger conversation where businesses are considering the broader environmental impact of business operations. As companies rightfully focus on their ecological responsibilities, modular construction stands out as a practical, powerful solution.

We dive deeper into this approach in our article on energy-efficient modular buildings that are both sustainable and cost-effective.

Choosing a sustainable building method is a proactive step that puts you ahead of the curve. With more companies prioritizing green initiatives, project slots for these forward-thinking methods get booked well in advance. To ensure your timeline aligns with both your operational and sustainability goals, it pays to start the conversation early.

Request a Quote today to get a free, no-obligation design and see how a sustainable modular building can benefit your facility.

Start Your Modular Project with an Expert Partner

Knowing the benefits of modular construction is one thing. Putting that knowledge to work for your facility is the next, most important step. At Material Handling USA, our job is to make the advantages of speed, cost savings, quality, and sustainability a reality for you.

We start by combining competitive pricing and the fastest shipping in the industry with quality materials and products. But our real value is in the partnership. We believe a successful project begins with a clear vision, which is why we offer something unique right from the start.

Free Design and Layout Services

You shouldn't have to guess what your project will look like or if it will work. Before you commit to anything, our team provides free layouts and designs with no obligation. This isn't a generic template; it's a chance to see the perfect solution for your space and explore the possibilities without any upfront investment.

Our experts will work with you to translate your operational needs into a functional, efficient plan. This hands-on process ensures the final design delivers on all the benefits of modular construction we've covered. You'll see exactly how the new structure integrates with your workflow, optimizes your floor space, and meets your specific goals. It's a practical, no-risk way to get started.

The path to a more efficient and cost-effective facility starts with a simple conversation. Our design consultation is the bridge between understanding the theory of modular and seeing its practical application for your business.

A Partnership You Can Rely On

Choosing the right building method is crucial, but choosing the right partner is just as important. We bring years of hands-on experience to every project, guiding you through each phase from the initial sketch to the final installation. Our commitment is to make the entire process clear, straightforward, and effective.

Here’s what you can expect when working with us:

- Expert Guidance: Our team knows the ins and outs of modular solutions for warehouses, manufacturing facilities, and everything in between.

- Quality Materials and Products: We use tough, reliable materials engineered for demanding industrial and commercial environments.

- Fastest Shipping and Delivery: From the first drawing to final delivery, our priority is getting your facility up and running as quickly as possible.

With the growing demand for smart building solutions, our production schedules fill up well in advance. Getting our design team involved early is the best way to secure a project timeline that meets your targets. You gain the benefit of thoughtful planning and avoid the headaches of last-minute delays.

Ready to see what’s possible for your facility? Contact Us at (800) 326-4403 to start your free, no-obligation design and discover how modular construction can truly transform your operations.

Your Top Questions About Modular Construction Answered

When you're looking at a new way to build, questions are a good thing. For managers and buyers doing their research, getting straight answers on the practical side of modular is a key part of the process. Here are the most common questions we get, with direct answers to help you move forward with confidence.

Is Modular Construction as Durable as Traditional Construction?

Yes, and in some ways, it can be even better. Modular buildings are engineered to meet—and often exceed—the exact same building codes and standards as structures built on-site. We use the same high-quality materials you'd expect: steel, concrete, and industrial-grade finishes.

The real difference is where the work happens. Our modules are assembled in a climate-controlled factory. This protects every component from weather damage and allows our teams to ensure the precision of the assembly. What you get is an incredibly durable, long-lasting building ready for demanding commercial or industrial work.

How Much Design Flexibility Do I Really Have?

You have a lot more than you might think. While the process is standardized for efficiency, the final building is anything but. You can customize just about everything: layouts, exterior finishes, interior features, and specialized add-ons to perfectly match your operation.

At Material Handling USA, creating custom solutions is what we do. We offer free design services to ensure your new modular building doesn't just fit the space—it fits your workflow, whether that's for an office, a high-tech lab, or secure storage.

What Does the Permitting Process Look Like?

It’s often much faster. Because the individual modules are inspected at the state level right in the factory, those approvals can happen while your on-site foundation work is getting done. This parallel approach sidesteps the frustrating linear delays that can slow down a traditional build.

Our team has years of experience navigating local requirements across different industries and municipalities. We’ll provide the documentation and support you need to keep your project moving smoothly.

Can I Move or Expand Modular Buildings Later On?

Absolutely. This is one of the biggest long-term advantages of going modular—it protects your investment. The inherent adaptability is one of the core benefits of modular construction. These structures are designed from day one to be easily reconfigured, expanded with new modules, or even completely relocated to a new site.

This gives your facility the power to grow and change right alongside your business. Instead of facing costly demolition and disruptive reconstruction, you can adapt your space quickly and efficiently.

Understanding these key points makes it much clearer how a modular approach can be a game-changer for your facility. With demand high, projects are being planned further out than ever. Starting the conversation now is the best way to secure a timeline that lines up with your goals.

The expert team at Material Handling USA is ready to help you explore what’s possible.

Contact Us for a free quote and layout design, or Call (800) 326-4403 to talk with a specialist today.