Gravity flow racking is a high-density storage solution that uses inclined rollers to automatically move inventory from a loading aisle to a picking aisle. This system creates a perfect First-In, First-Out (FIFO) inventory flow, making it an ideal solution for date-sensitive or perishable products. For warehouse managers and buyers, this means a significant boost in storage density and picking speed with minimal manual effort.

Understanding Gravity Flow Racking

Think of it as a giant, industrial-grade vending machine for your warehouse. You load products in the back, and they automatically slide forward, perfectly positioned for the next order. This simple concept is the power behind gravity flow racking. It’s a dynamic storage system that uses sloped shelves fitted with rollers or wheels to maximize both space and efficiency.

When a pallet or carton is placed on the high end of the lane, gravity takes over. The item glides smoothly down the inclined rollers toward the picking face on the opposite side. As soon as the front item is picked, the one behind it automatically moves into place, ensuring the next product is always ready to go. This design creates a clean separation between replenishment (loading) and fulfillment (picking), reducing aisle congestion and streamlining your entire workflow.

Key System Components

While the concept is straightforward, a gravity flow system relies on several key components working together flawlessly:

- Upright Frames: These are the vertical steel pillars that form the structural backbone of the entire system.

- Beams: Horizontal supports that connect the uprights, creating the shelf levels where the flow lanes are installed.

- Flow Lanes: These are the channels fitted with rollers or skate wheels that allow inventory to move. Their design is customized based on the products being stored.

- Braking Systems: For heavy loads, speed controllers or brakes are integrated directly into the lanes to manage the speed of pallets, ensuring safe and controlled movement.

Pallet Flow vs. Carton Flow

Gravity flow racking is available in two main configurations, each engineered for different inventory types:

- Pallet Flow Racking: This is the heavy-duty option, designed to handle full pallets that can weigh thousands of pounds. It is the perfect fit for high-volume products where strict FIFO is critical, such as in food and beverage distribution.

- Carton Flow Racking: This is a lighter-duty version designed for individual boxes, totes, and cartons. It is frequently used in piece-picking and split-case operations common in e-commerce fulfillment centers and parts distribution warehouses.

The demand for this level of efficiency is growing. The global gravity flow racks market is currently valued at $2.5 billion and is projected to grow at a compound annual rate of 7% through 2033. This growth is largely driven by the e-commerce sector's continuous need for faster, denser storage solutions. You can read the full research about gravity flow rack market trends to learn more.

The Core Benefits of Gravity Flow Systems

Transitioning to a gravity flow system is an upgrade that delivers measurable dividends across your entire operation. By moving from static shelving to dynamic storage, facilities can unlock significant gains in space, labor efficiency, and inventory control. When you add it all up, the return on investment is compelling.

Maximize Your Storage Density

The most immediate benefit of gravity flow racking is a substantial increase in storage density. Traditional selective racking requires an aisle for every row of pallets. Gravity flow systems completely change this model by consolidating inventory into deep, back-to-back lanes.

This simple shift can increase your storage capacity by up to 75% within your existing footprint. For a growing business, that’s a game-changer. Instead of incurring the cost of an expansion or a move to a new facility, you can better utilize the vertical and horizontal space you already have. The freed-up floor space can then be repurposed for value-added activities like packing stations, staging areas, or new production cells.

Boost Labor Efficiency and Safety

Gravity flow racking improves workflow by creating dedicated aisles for loading and picking. This separation immediately reduces congestion from forklifts and foot traffic, leading to a safer and more organized environment.

With fewer interactions between stockers and pickers, travel times decrease and the risk of accidents is lowered. Your team becomes more productive because products are always queued up and ready at the pick face.

- Less Travel Time: Forklift operators can deposit several pallets into a single lane without entering the picking aisles. This means less distance traveled and less fuel or battery consumption.

- Faster Picking: Order pickers never have to wait for replenishment. The next item is always front and center, which increases pick rates and gets orders out the door faster.

Ultimately, this efficiency boost allows you to process more orders with the same team, which has a direct, positive impact on your labor costs and overall throughput.

By separating replenishment from picking, warehouses can reduce forklift travel by as much as 80% for certain high-volume SKUs, leading to substantial savings in both time and equipment wear.

Enforce Flawless Inventory Rotation

If you handle perishable or date-sensitive goods, strict First-In, First-Out (FIFO) inventory management is essential. Gravity flow racking automates this process perfectly.

Pallets or cartons are loaded from the back and glide forward to the picking face, guaranteeing that the oldest products are always picked first. This built-in rotation system virtually eliminates the risk of product spoilage, obsolescence, and waste. It also removes the need for manual stock rotation, a tedious and error-prone task. With gravity flow, FIFO isn’t just a policy; it's physically built into your storage system.

Ready to see how these benefits could translate into real numbers for your facility? Optimizing your layout is easier than you think, and planning ahead helps secure faster installation timelines. Request a Quote from our experts for a free, no-obligation layout and pricing.

Comparing Pallet Flow and Carton Flow Racking

While pallet flow and carton flow systems both operate on the principle of gravity, they are engineered to solve different challenges on the warehouse floor. It's like choosing between a heavy-duty freight truck and a nimble delivery van. Both move goods, but they are built for entirely different loads and purposes.

Understanding their distinct applications is the first step in selecting the right gravity flow racking for your specific inventory and workflow. One system is built for moving massive quantities in bulk, while the other is focused on speed and precision for fulfilling individual orders. Making the right choice is key to maximizing density, efficiency, and your return on investment.

Pallet Flow Racking: The Heavy Lifter

Pallet flow systems are the workhorses of the gravity flow world. These racks are built tough to handle full, heavy pallet loads weighing thousands of pounds. This makes them a perfect fit for distribution centers, manufacturing plants, and food and beverage operations that move high volumes of the same SKUs daily.

By loading pallets several deep into a single lane, these systems create incredible storage density while naturally enforcing a strict FIFO rotation, a critical requirement for perishable goods. The heavy-duty construction and specialized rollers are designed for consistent performance under serious weight, year after year.

Carton Flow Racking: The Piece-Picking Specialist

On the other end of the spectrum, carton flow systems are all about speed and accuracy in piece-picking operations. Instead of full pallets, these racks are designed for lighter loads like individual boxes, cases, and totes. You’ll find them in e-commerce fulfillment centers, retail backrooms, and parts distribution hubs where workers are picking individual items to build customer orders.

You can explore various carton flow rack configurations to see how they integrate into different picking modules. The benefit of carton flow is how it presents inventory right at the pick face, making the process more ergonomic for the picker, which reduces strain and boosts accuracy. The main goal is to keep a wide variety of SKUs ready for fast, efficient processing of a high number of smaller, multi-item orders.

The biggest difference comes down to scale. Pallet flow manages inventory by the pallet. Carton flow manages it by the case or even the individual piece. This directly shapes the speed and detail of your picking operations.

This table outlines the core differences between these two powerful gravity flow solutions.

| Feature | Pallet Flow Racking | Carton Flow Racking |

|---|---|---|

| Load Type | Full pallets | Individual cartons, totes, boxes |

| Load Capacity | 2,000 to 5,000+ lbs per lane | 25 to 75 lbs per shelf level |

| Typical Application | High-volume SKU distribution, food & beverage, manufacturing | E-commerce fulfillment, piece-picking, retail, parts storage |

| Inventory Rotation | First-In, First-Out (FIFO) by pallet | First-In, First-Out (FIFO) by case |

| Primary Benefit | Maximum storage density for bulk goods | Increased pick speed and SKU accessibility |

Choosing between them isn't a guess; it requires a clear analysis of your product mix and operational goals. Our team can help with that. We provide free layouts with no obligation to determine which system will deliver the best results for your unique setup. Contact Us to start the conversation.

How to Design a Custom Gravity Flow System

An effective gravity flow system is not an off-the-shelf product. It’s an engineered solution, built from the ground up around your unique inventory and workflow. Designing a system that works perfectly means digging into the details to guarantee smooth, consistent, and safe product movement from day one.

The process begins with a deep dive into your SKUs. The weight, dimensions, and even the condition of the bottom of your pallets or cartons are the building blocks for every subsequent decision. A heavy pallet with an uneven bottom needs a completely different setup than a lightweight, uniform carton.

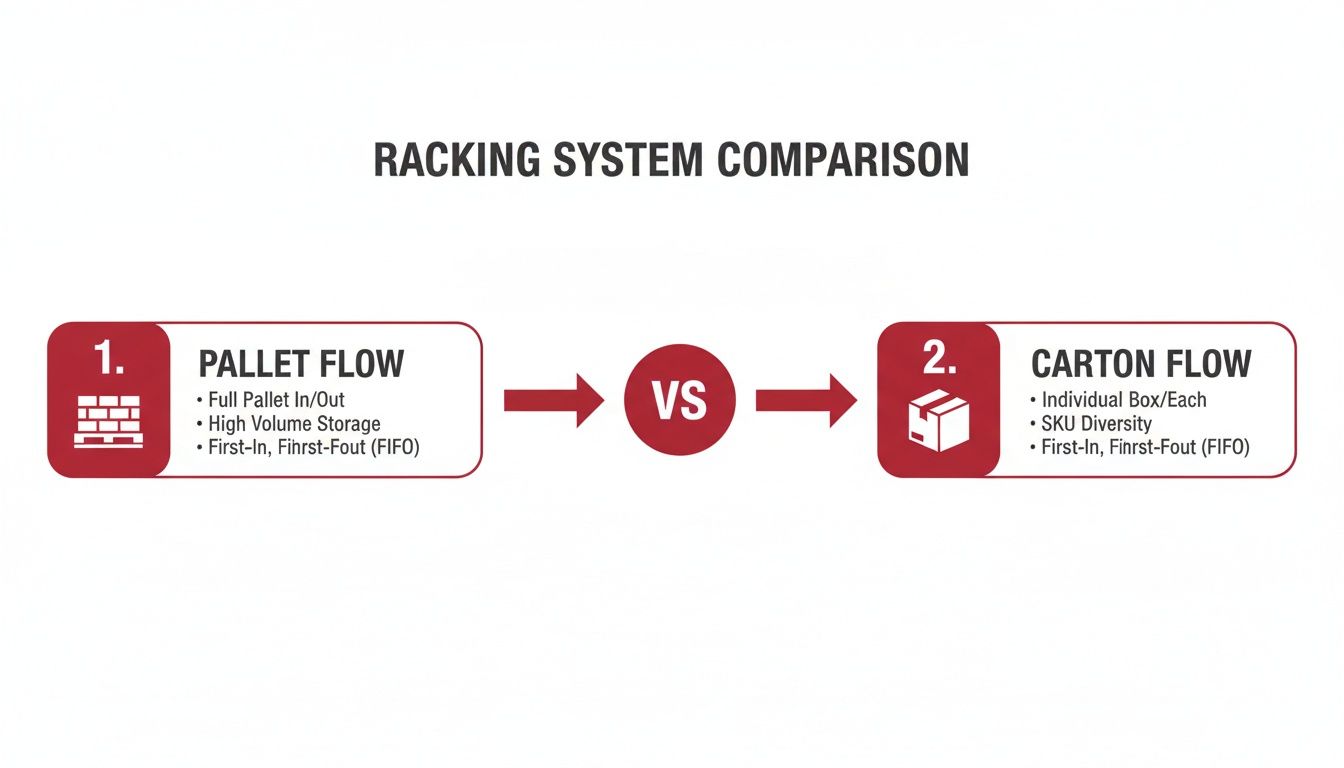

This infographic provides a high-level comparison of the two main types of gravity flow: Pallet Flow and Carton Flow. The initial choice between them is dictated by these very inventory characteristics.

As you can see, determining whether you are moving heavy pallets or lighter cartons is the first fork in the road of the design process.

Matching Components to Your Inventory

Once we know what you’re storing, we can select the right components to move it. This is where real-world experience is critical, because the wrong choice can lead to stalled products or dangerously fast flow rates.

You are generally looking at two main options for roller systems:

- Skate Wheel Rollers: Imagine a series of steel or plastic wheels spinning on a single axle. These are perfect for cartons and totes with flat, solid bottoms. They provide excellent flow for lighter items and are a cost-effective choice for many piece-picking operations.

- Full-Width Rollers: These are single, robust rollers that span the entire lane width. They offer much more surface contact, which makes them essential for handling heavy pallets or products with inconsistent bases, like bagged goods or wire mesh containers.

The material of the pallet or tote also matters. A standard wooden pallet glides very differently than a plastic one, and our team factors in these unique friction coefficients when finalizing the design.

Calculating Lane Depth and Pitch

The physical layout of the lanes is just as important as the rollers inside them. Lane depth and the pitch—the angle of the slope—must be calculated with precision to create a reliable system.

The optimal pitch for a gravity flow lane is a delicate balance. Too shallow, and pallets will hang up, requiring manual intervention. Too steep, and they can accelerate down the lane, creating a serious safety hazard at the picking face.

Our design process involves specific calculations based on your product weight and roller selection to lock in that perfect angle, which typically falls between 3/8 to 1/2 inch per foot. This ensures pallets move smoothly and come to a gentle, controlled stop exactly where you need them.

Lane depth, or how many pallets a single lane can hold, is determined by your inventory levels and throughput requirements. Deeper lanes are fantastic for storage density, but they demand careful engineering to manage the cumulative weight and pressure (known as "back pressure") on the pallets at the front. Our experts use specialized braking systems inside these deep lanes to control flow speed and safely absorb that pressure.

The Value of Professional Design

Trying to manage all these variables without extensive experience can lead to problems. A DIY setup or a generic configuration often results in costly issues and safety risks. That is precisely why we offer our design and layout services for free, with no obligation.

When you partner with our team, you gain access to decades of expertise in creating high-performance storage solutions. We ensure your system is perfectly calibrated for your specific operation, preventing future bottlenecks and maximizing your return on investment. With warehouse projects often facing planning challenges, getting our design team involved early helps you secure your equipment and lock in installation schedules, avoiding potential industry-wide delays. Learn more about how we develop full warehouse design solutions that are built to grow with your business.

Keeping Your System Safe and Running Smoothly

A high-performance gravity flow racking system is a valuable asset, but its true worth comes from operating safely and reliably every day. Protecting your team and your investment means committing to consistent safety protocols and proactive maintenance. By building these habits into your daily operations, you not only create a safer warehouse but also extend the life of your system, ensuring it delivers value for years to come.

It all starts with quality materials. We build every gravity flow racking system with high-grade, durable steel and tough components to provide a solid foundation for long-term performance. However, your daily practices are just as critical to maintaining it.

Essential Day-to-Day Safety Procedures

Proper daily use is your primary defense against accidents and damage. Training your team on these fundamentals is essential.

- Know Your Load Limits: Every system is engineered for specific weight capacities. Ensure these limits are clearly posted on the racking and that every forklift operator and team member adheres to them. Overloading is one of the fastest ways to cause a major structural failure.

- Load Pallets Correctly: Operators must be trained to place pallets onto the flow lanes gently. Dropping or slamming pallets into place can damage rollers, bearings, and frames, leading to expensive repairs and unsafe conditions.

- Keep Aisles Clear: Loading and picking aisles must be kept free of obstructions like stray pallets, debris, or other blockages. Clear paths are crucial for safe forklift movement and preventing trip-and-fall hazards.

A Practical Maintenance Checklist

Regular inspections are key to catching small issues before they become major problems. A simple but consistent maintenance routine can prevent significant issues down the road.

A proactive maintenance schedule doesn't just prevent accidents; it preserves the efficiency of your gravity flow racking. Identifying a single damaged roller early can prevent a major product jam that halts your entire picking line.

Use this checklist as a starting point for your weekly or monthly inspections:

- Inspect Rollers and Wheels: Look for any rollers that are damaged, stuck, or missing. Ensure they spin freely and are securely seated in the lane.

- Check Brake Systems: On pallet flow systems, verify that the speed controllers and brakes are functioning properly to keep pallet speeds under control.

- Examine the Structure: Scan for any signs of damage to uprights, beams, or anchors, especially dents from forklift impacts. Any compromised component should be reported and repaired immediately.

- Verify Lane Alignment: Check that the flow lanes have not shifted out of alignment. If they are crooked, pallets will not track correctly and may get stuck.

- Clean Out Debris: Regularly clear dust, pieces of broken pallets, and shrink wrap from the flow lanes. This debris is a common cause of jams.

Technological advancements are also making these systems smarter. For instance, new roller materials can reduce friction by 20%, making the flow smoother and more consistent. Modern systems are even incorporating IoT sensors for real-time inventory updates. Fueled by these improvements, the gravity racking market is expected to reach $2.8 billion by 2033. Discover more insights about the gravity flow racking market on Data Insights Market Research.

Implementing these safety and maintenance practices ensures your system functions as designed. If you need assistance setting up an inspection schedule or ordering replacement parts, our team is here to help. Call our specialists at (800) 326-4403 for expert support.

Securing Your ROI with Gravity Flow Racking

Investing in new warehouse infrastructure is a major decision, and the ultimate measure of success is your return on investment. A gravity flow racking system is not just another expense; it's a strategic move that directly addresses the biggest operational costs: space, labor, and inventory management.

When you connect the operational benefits to financial outcomes, the case becomes clear. Every advantage we've discussed translates directly into tangible savings and productivity boosts.

By radically increasing storage density, you get more value from every square foot you already own. This can mean postponing or completely avoiding the massive cost of expanding your facility. Separating loading and picking aisles reduces forklift travel time, which means lower fuel costs, less equipment wear, and a more productive team that can ship more orders with the same number of people.

From Operational Gains to Financial Wins

The numbers tell a powerful story. Perfect FIFO rotation slashes losses from product spoilage or obsolescence, turning potential write-offs into revenue. When your picking accuracy improves, you see fewer costly returns and build a better reputation with your customers. These are not just operational improvements; they directly impact your bottom line.

Here’s how those benefits stack up to boost your ROI:

- Reduced Capital Expenditure: Storing up to 75% more product in the same footprint allows you to delay plans for new construction or leasing another building.

- Lower Labor Costs: With less travel and product that automatically flows to the pick face, you can fulfill more orders with your current team, improving labor efficiency.

- Decreased Inventory Waste: Automated FIFO ensures your date-sensitive goods are sold in the correct order, protecting your profits by minimizing spoilage.

Planning for a More Profitable Future

Making this investment is also about preparing your operation for the future. As demand for warehouse efficiency continues to climb, project timelines for design, manufacturing, and installation are lengthening across the industry. Acting now helps you lock in a well-designed system and get ahead of these delays.

Partnering with us isn't just about buying racking; it's about investing in a more streamlined, scalable, and profitable future for your business. Our goal is to equip you with a system that performs on day one and adapts as you grow.

Getting your layout designed and your equipment scheduled sooner rather than later means you can implement these improvements on your timeline, not someone else's. The efficiency gains you capture next quarter are far more valuable than the ones you might get next year. For a deeper dive into optimizing your facility, check out our guide on warehouse optimization.

By choosing Material Handling USA, you get access to competitive pricing, the fastest shipping in the industry, and expert guidance every step of the way. Let us show you how a properly designed gravity flow racking system can transform your operations.

Ready to build a more efficient future? Call our experts at (800) 326-4403 or Request a Quote for your free, no-obligation design today.

Frequently Asked Questions

Upgrading to a system like gravity flow racking naturally brings up questions. It’s a significant investment, and you need the right information. Here are straightforward answers to the most common questions we receive.

What Is the Typical Lifespan of a Gravity Flow Racking System?

A quality gravity flow rack should be viewed as a long-term asset. When used and maintained correctly, a system from Material Handling USA is built to last 20 years or more.

Several factors influence this lifespan, including the quality of the steel, the operating environment (e.g., freezer vs. dry warehouse), the typical weight of your pallets, and adherence to a routine inspection schedule. Regular checks of the rollers and frame are the best way to maximize the life of your investment.

Can Gravity Flow Racking Be Integrated with Other Systems?

Absolutely. In fact, integration is one of their strengths. Gravity flow racks are designed to work well with other systems. They fit perfectly alongside selective pallet racking for overstock, connect seamlessly with conveyor systems for order picking, and can be integrated with any modern Warehouse Management System (WMS) for precise inventory tracking.

Our design team specializes in creating layouts that function as a single, efficient workflow, blending gravity flow with your existing infrastructure to enhance overall operational performance.

Integrating gravity flow racking isn't just about adding new shelves; it's about creating a cohesive material handling ecosystem where every component works together to improve throughput and accuracy.

How Do You Determine the Correct Incline for Flow Lanes?

Getting the incline, or pitch, correct is arguably the most critical part of the design process. It is not a "one-size-fits-all" scenario. The perfect angle is a careful calculation based on your pallet's weight, its bottom surface, the type of rollers used, and the desired flow speed.

If the angle is too shallow, pallets will stall, requiring manual intervention. Conversely, an angle that’s too steep is a safety risk, as pallets can gain too much speed. Our design process involves precise calculations for your specific products to engineer a safe, controlled, and consistent flow.

Is This Racking Suitable for Freezer or Cold Storage Environments?

Yes, it is an excellent choice for cold storage. Because gravity flow is so dense, it allows you to store more product in expensive refrigerated space. You achieve more storage in a smaller footprint, which can positively impact your energy costs.

However, a standard system cannot be installed in a freezer. These environments require specialized components. We use systems with rollers and bearings specifically engineered to perform in sub-zero temperatures without becoming brittle or seizing up. This ensures your rack remains durable and functions as smoothly in the cold as it would anywhere else.

Ready to get answers for your specific facility? The experts at Material Handling USA can put together a free layout and quote to show you exactly how gravity flow racking could work for you.