Getting a handle on shipping box dimensions is about more than just making sure your product fits. It’s a core business strategy that directly impacts your operational efficiency and, more importantly, your profitability. The right size box can slash carrier fees, give your products better protection, and even make life easier for your warehouse crew.

When you use a box that’s too big, you’re literally paying to ship air—a classic, costly mistake in today's logistics game.

Why Shipping Box Dimensions Control Your Bottom Line

For managers and buyers, mastering the details of box dimensions is one of the most powerful ways to control costs. Just one inch can be the difference between a standard shipping rate and a pricey surcharge. It can waste precious warehouse space and dramatically increase the odds of your product getting damaged on its journey.

Optimizing this fundamental piece of your logistics puzzle delivers returns that ripple across your entire supply chain.

This guide will break down everything you need to know, from the right way to measure Length x Width x Height (L×W×H) to how carriers use that info to calculate your final bill. By focusing on how this works in the real world, you’ll see how picking the right box gives you a real competitive edge.

The Foundation of Efficient Shipping

First things first, every corrugated box has two sets of measurements you need to care about:

- Interior Dimensions: This is your usable space—what’s actually inside the box. It’s the most critical measurement for making sure your product fits snugly, with just enough room for protective cushioning like bubble wrap or foam inserts.

- Exterior Dimensions: This is what the carriers see and what they use to calculate your shipping costs. It accounts for the thickness of the cardboard itself and determines how much real estate your package takes up on a truck or plane.

Getting these two mixed up is a recipe for trouble. You might order boxes that are too small for your items or get hit with surprise fees because your package tipped over a carrier's size limit.

The Hidden Cost of "Shipping Air"

If there's one reason to get this right, it's to avoid the sting of dimensional (DIM) weight. This isn't just industry jargon; it's the pricing model that drives shipping costs for all the major players, including FedEx, UPS, and USPS.

In simple terms, DIM weight is a calculation that determines the theoretical weight of a package based on its size. The carrier will charge you for whichever is greater: the actual weight of the package or its calculated DIM weight.

This whole system exists so that carriers get paid fairly for shipping big, light items that hog space. For your business, this means a large box with a lightweight product inside can cost just as much to ship as a small, heavy brick. To better manage these expenses, it's worth looking into different post-campaign shipping charge strategies.

By choosing a box that offers a snug, secure fit, you get rid of that wasted space. Less space means a lower billable weight for your shipment. It’s a simple decision that translates directly into lower freight costs and a healthier bottom line. For help finding the perfect fit, Contact Us for a free layout and design consultation.

How to Measure a Box the Right Way

Getting your shipping box dimensions wrong is an easy mistake to make, but it can cost you. We're talking surprise carrier fees, logistical nightmares, and even damaged products. The good news is that measuring a box correctly is simple once you know the industry standard method.

Nailing these measurements means your products will fit snugly, your shipping rates will be accurate, and your whole operation will run a lot smoother. It's a small step that prevents big headaches down the line.

Interior vs. Exterior Dimensions: The Critical Difference

Every corrugated box actually has two sets of measurements. Knowing which one to use—and when—is the key to avoiding costly mix-ups.

-

Interior Dimensions: This is all about the usable space inside the box. These are the numbers that matter when you're figuring out if your product will fit, especially with enough room for protective cushioning like bubble wrap or foam. When you see box sizes listed for sale, they're almost always referring to these interior specs.

-

Exterior Dimensions: This is the measurement of the box from the outside. These are the numbers your carrier—think FedEx or UPS—cares about. They use these exterior dimensions to calculate shipping costs and figure out how much real estate your package takes up on a truck or pallet.

Think of it this way: the interior dimensions have to be perfect for your product, while the exterior dimensions have to fit into the carrier's world. Get them confused, and you could be looking at damaged goods or an unexpected bill.

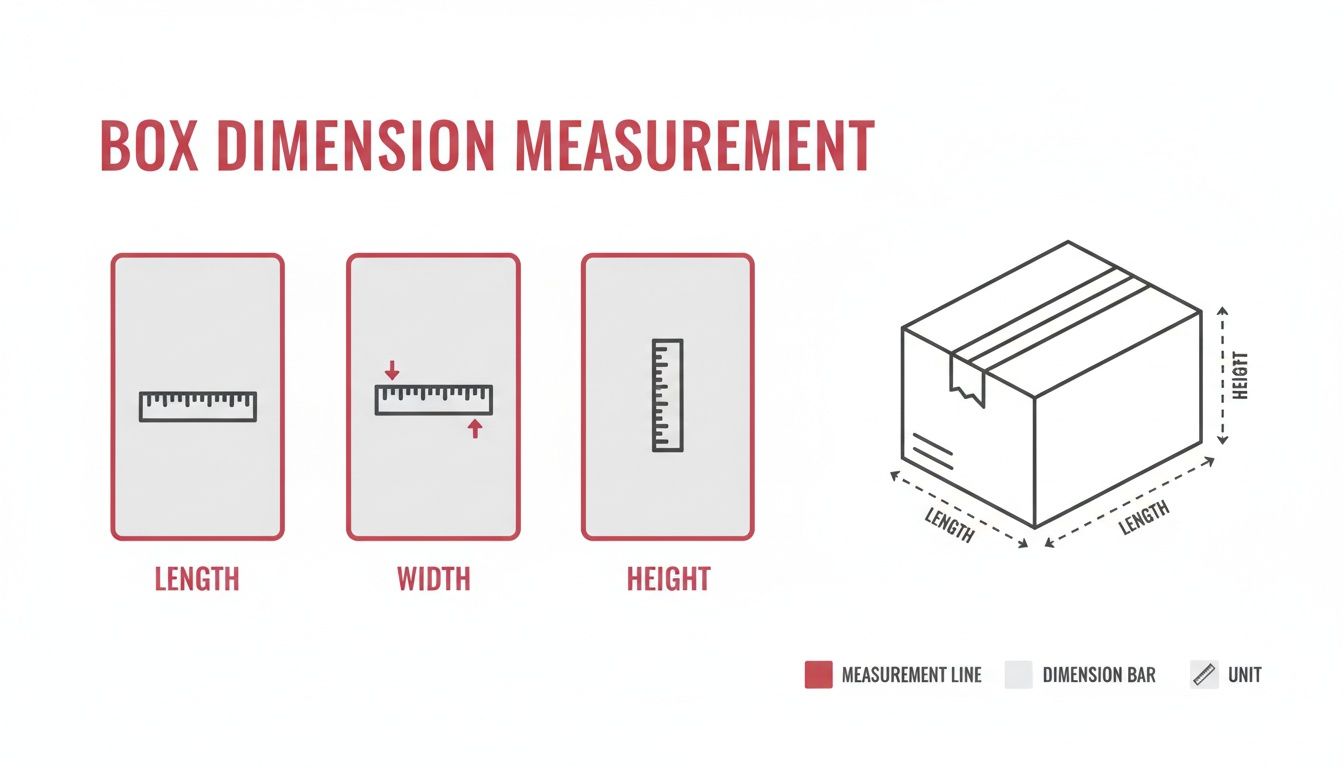

The Standard L x W x H Measurement Process

When you see dimensions written as Length x Width x Height (L x W x H), that order isn't just a suggestion—it's an industry-wide convention that keeps everyone on the same page.

Here’s the right way to measure, step-by-step:

- Find the Length: Put the assembled box down with the top flaps open. The Length is always the longest side that has a flap.

- Find the Width: The Width is the shorter side that also has a flap.

- Measure the Height: The Height (sometimes called Depth) is the distance from the bottom of the box to the top. It’s the only dimension that doesn't have a flap.

Following this simple order prevents confusion, ensuring your warehouse team and the carrier’s sorting facility are speaking the same language.

Key Takeaway: For the most accurate results, always measure an assembled but empty box. A flattened box won't give you the true interior dimensions you need to guarantee your products will actually fit.

Best Practices for Spot-On Measurements

To dodge common errors and keep your measurements carrier-compliant, stick to these simple but effective habits.

- Round to the Nearest Inch: Most major carriers want dimensions rounded to the nearest whole inch. Getting this wrong, even by a little, can trigger those dreaded billing adjustments.

- Use a Real Tape Measure: Don't eyeball it. A flimsy or worn-out tape measure can lead to bad reads. A solid, rigid measuring tool is your best bet for accuracy.

- Write It Down: Keep a clear log of the interior and exterior dimensions for every box size you use. This data becomes your playbook for managing inventory and forecasting shipping costs.

Getting these details right from the start saves time, money, and a whole lot of frustration. If you're struggling to find the perfect box for your products, our team is here to help. Request a Quote today for a free, no-obligation design consultation.

Understanding the Impact of Dimensional Weight

Dimensional weight—you’ll often hear it called DIM weight—is one of the most misunderstood and frustrating parts of managing shipping costs. For a lot of businesses, it’s a silent budget killer. Carriers like FedEx, UPS, and USPS don’t just charge you for how heavy a package is; they charge you for the space it takes up on their trucks and planes.

Think of it like this: a five-pound box of feathers takes up way more room than a five-pound dumbbell. That extra space is valuable real estate to a carrier, and DIM weight is how they bill you for it.

The rule of thumb is simple: carriers calculate both the actual weight and the DIM weight of your package. You get charged for whichever is greater. This is precisely why a large, lightweight item can cost a surprisingly huge amount to ship.

How DIM Weight Is Calculated

Getting a handle on the DIM weight formula is the first step toward predicting your costs and making smarter packaging choices. Thankfully, the math itself is pretty straightforward.

The Formula: (Length × Width × Height) / DIM Divisor = Dimensional Weight

The DIM Divisor is a number set by each carrier. A lower divisor means a higher DIM weight, which translates to a more expensive shipment. This number isn’t universal; it can change from carrier to carrier and even between different services from the same company.

First things first, you need to get your measurements right.

Nailing down the correct exterior length, width, and height is the most critical step you can take to keep these costs under control.

A Practical Example of DIM Weight in Action

Let’s see how this plays out in the real world. Imagine you’re shipping a set of lightweight plastic parts. The box and its contents have an actual weight of 10 pounds, but you’ve packed them in a big 20" × 18" × 18" box to be safe.

Using a standard domestic DIM divisor of 139, here’s what happens:

- Volume: 20 × 18 × 18 = 6,480 cubic inches

- DIM Weight: 6,480 / 139 = 46.61 pounds

The carrier will round that up to 47 pounds. Since the 47-pound DIM weight is much greater than the 10-pound actual weight, you’re getting billed for a 47-pound package. That’s a massive cost increase caused entirely by picking the wrong box.

If you ship internationally, especially to Australia, the concept is similar but often called cubic weight. It's a good idea to learn how to calculate cubic weight for Australian shipping like a pro to avoid any surprises.

Comparing DIM Divisors from Major Carriers

The DIM divisor is a crucial piece of the pricing puzzle. These numbers can and do change, but knowing the current standards helps you estimate your costs far more accurately. Of course, for real-time, precise figures, it's always best to use an up-to-date tool. You can use our own shipping calculator to compare rates right now.

To give you a general idea, here’s a look at the standard DIM divisors for major U.S. carriers.

Common DIM Divisors for Major US Carriers

This table outlines the standard dimensional weight divisors used by major shipping carriers. A lower divisor increases the billable DIM weight.

| Carrier | Standard DIM Divisor (Domestic) | Key Considerations for Shippers |

|---|---|---|

| FedEx | 139 | Applies to both FedEx Ground and FedEx Express services. International rates may use a different divisor. |

| UPS | 139 | This is standard for their daily rates. Be aware that retail rates might use a higher divisor (166) for packages under one cubic foot. |

| USPS | 166 | Applies to Priority Mail, Priority Mail Express, and Parcel Select for any package measuring over one cubic foot. |

As you can see, the lower 139 divisor used by FedEx and UPS means your packages are much more likely to be billed based on their DIM weight. This makes one thing crystal clear: your most effective strategy for cutting unnecessary shipping charges is to select the absolute best-fit box from the very start.

Choosing the Right Standard Box for Your Industry

Let's be honest, picking a shipping box isn't a one-size-fits-all game. The perfect box for a boutique shipping delicate cosmetics would be a disaster for a manufacturer sending out heavy industrial parts.

Knowing the most common box styles and what they're built for is the first step. This isn't just about finding a container; it's about protecting your products, slashing your shipping costs, and making your warehouse team's life easier.

Common Box Styles and Their Best Applications

While the world of corrugated boxes is vast, a few key players do most of the heavy lifting for logistics operations. Getting to know these workhorses helps you match the right design to your products, ensuring you're not overspending or risking damage.

- Regular Slotted Carton (RSC): This is the box you see everywhere. All its flaps are the same length, and the two outer flaps meet neatly in the middle. RSCs are incredibly versatile and cost-effective, making them the go-to choice for almost everything in e-commerce, retail, and general manufacturing.

- Full Overlap Container (FOL): With an FOL box, the outer flaps don't just meet—they extend all the way across, completely overlapping. This creates a double layer of corrugated board on the top and bottom, giving it serious extra strength. It’s the perfect choice for heavy or fragile items that need robust support during transit.

- Five Panel Folder (FPF): Ever wonder how long, flat items like picture frames, mirrors, or books get shipped so securely? The FPF is often the answer. It’s a single piece of corrugated board that wraps snugly around the product, offering a secure, almost custom-fit feel.

Connecting Standard Sizes to Real-World Uses

Standard box sizes are popular for a reason—they provide predictable, battle-tested solutions for the most common shipping jobs. Seeing how these dimensions fit into your industry can make purchasing a whole lot simpler.

| Box Size (Inches) | Industry Application | Key Benefit |

|---|---|---|

| 6 x 6 x 6 | E-commerce, Cosmetics | Perfect for small, individual items. Minimizes void fill and DIM weight. |

| 12 x 12 x 12 | General Retail, Parts Distribution | A versatile cube for a huge variety of goods. Stacks like a dream. |

| 18 x 18 x 16 | Industrial, Manufacturing | Ideal for bulkier components or shipping multiple smaller items together. |

| 24 x 18 x 18 | Law Enforcement, Evidence Storage | Provides ample, secure space for larger items like electronics or evidence bags. |

Choosing from our inventory of wholesale corrugated boxes for bulk shipping gets you the quality you need at competitive prices.

The Global Impact of Standardization

The box sizes we take for granted today exist because of a massive shift in global logistics that happened decades ago. Before the 1960s, shipping was pure chaos. Loose cargo was loaded piece by piece, leading to damaged goods and epic port delays.

Everything changed when the International Organization for Standardization (ISO) introduced standard shipping containers in 1965. The 20-foot (TEU) and 40-foot (FEU) containers slashed cargo handling times by over 90% and truly kickstarted modern global trade.

For today’s logistics managers, this history lesson has a practical takeaway: pick box sizes that nest perfectly onto pallets, which in turn fit flawlessly into those standardized containers. That interlocking efficiency is the very backbone of the global supply chain.

Solving Packaging Challenges in Specialized Fields

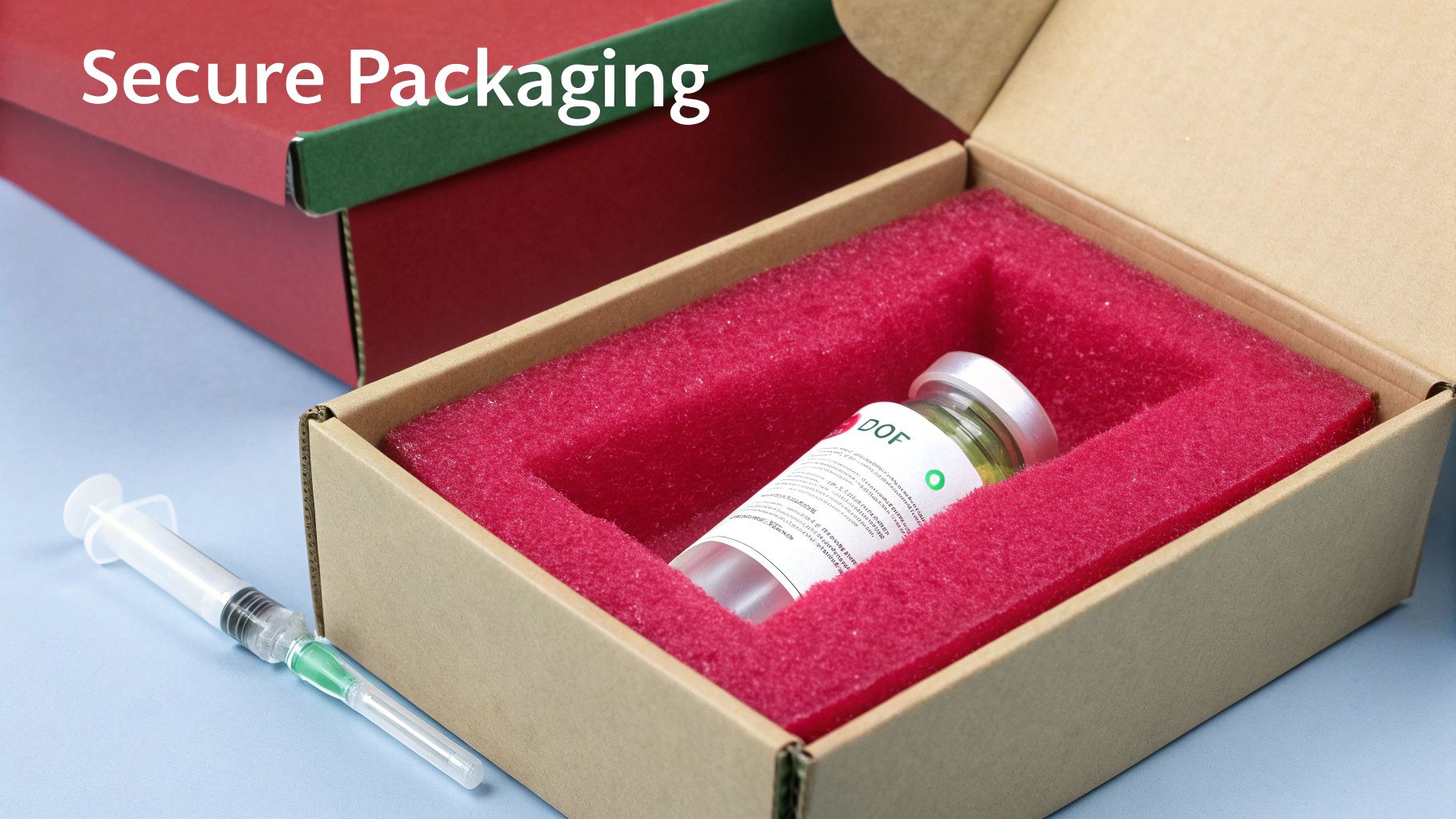

For industries like healthcare, laboratories, and law enforcement, packaging is so much more than just getting something from A to B. It’s about ironclad compliance, total security, and the absolute integrity of what's inside. When the stakes are this high, standard shipping box dimensions just don’t cut it, creating unique challenges that call for highly specialized solutions.

Think about it—when you're maintaining a chain of custody for evidence or protecting a critical lab sample, the box you choose is non-negotiable. Precision is everything. The container becomes a vital part of the protocol, not just a throwaway carton.

Healthcare and Laboratory Compliance

In medical and research settings, a box has to do more than just hold things. It needs to shield sensitive biological materials from temperature swings, physical shock, and any chance of contamination. Off-the-shelf boxes from a catalog rarely meet these incredibly strict standards.

This is where purpose-built containers make all the difference. For these sectors, the key features are:

- Insulated Shippers: These are boxes engineered with materials like expanded polystyrene (EPS) foam. Their whole job is to maintain a stable internal temperature—a must-have for shipping vaccines, blood samples, and other biologics.

- Custom Foam Inserts: Imagine perfectly cut foam that cradles every vial, petri dish, or piece of delicate lab equipment. This prevents any movement that could ruin a sample or damage an expensive instrument.

- Regulatory Adherence: Many shipments are governed by strict regulations that dictate everything from packaging strength and labeling to leak-proofing. Using a certified box isn't a "nice to have"; it's often a legal requirement.

Getting the interior dimensions just right to fit these protective elements is crucial for both staying compliant and ensuring the shipment arrives intact.

Security for Law Enforcement and Evidence Storage

For any police department or legal agency, maintaining the chain of custody is the single most important rule in evidence handling. The packaging itself is a critical link in that chain, offering security and a clear, tamper-proof record.

A standard cardboard box simply doesn't offer the necessary features. Evidence packaging must be tamper-evident, durable, and properly sized to prevent any alteration of the contents from the crime scene to the courtroom.

Key packaging features for these secure applications include:

- Tamper-Evident Designs: Boxes with special seals or interlocking tabs that make it obvious if someone has tried to open them are essential.

- Durable Construction: Evidence boxes have to withstand a lot of handling without breaking down. This usually means heavy-duty corrugated board or even hard plastic materials.

- Precise Sizing: An oversized box allows evidence to slide around, risking damage or contamination. A custom-fit box keeps items exactly as they were collected.

Custom Solutions for High-Value and Irregular Items

Many industries deal with equipment that is not only expensive but also oddly shaped. Trying to cram a complex piece of machinery or a sensitive electronic device into a standard-sized box is a recipe for disaster and huge financial loss.

This is where custom-sized boxes become a strategic advantage. They provide a tailored fit that eliminates the need for tons of void fill that often doesn't work anyway. The evolution of shipping containers actually reflects this same drive for efficiency. American innovation led to the 53-foot container in 1989, which can hold a whopping 60% more cargo than a standard 40-foot container—perfect for North American logistics. For warehouse managers, this highlights the principle of selecting box dimensions that maximize pallet space for these larger domestic hauls, whether you're shipping giant machines or tiny parts. You can learn more about the history of intermodal container development on Wikipedia.

Whether you need a specialized insulated shipper or a tamper-evident evidence box, the right solution protects your assets and ensures operational integrity. At Material Handling USA, we understand these unique pressures. We offer free layouts and designs with no obligation to help you find the perfect fit. Contact Us or Call (800) 326-4403 to speak with an expert about your specific packaging needs.

Partner with Us for Your Packaging Solutions

Getting a handle on shipping box dimensions isn't just a logistical chore anymore—it's a powerful strategic move for your business. The key lessons are clear: accurate measurement is your foundation, dimensional (DIM) weight is a direct hit to your budget, and the right box is an asset that protects both your products and your profits. When you take control of these elements, you can slash expenses, stop product damage in its tracks, and make your entire warehouse operation run smoother.

At Material Handling USA, we provide the high-quality materials and expert guidance you need to put these principles into practice. Our commitment to competitive pricing and the fastest shipping and delivery in the industry means you get the solutions you need, right when you need them. Think of us as more than just a supplier; we're your dedicated packaging partner.

Your One-Stop Shop for Packaging Needs

Whether you need standard-sized boxes that are ready to ship today or a completely custom solution designed for your unique products, our team is ready to help. We get that every operation has its own hurdles, from securing delicate medical equipment to keeping up with high-volume e-commerce fulfillment.

Our goal is to provide packaging that not only fits your products but also fits perfectly into your operational workflow and budget. This approach saves you time and eliminates costly trial and error.

We believe in providing real value from the very first conversation. That’s why we offer free layouts and designs with no obligation, letting you explore potential solutions without any upfront investment. Our specialists will work with you to understand your specific requirements and map out a packaging strategy that delivers maximum efficiency and protection.

Take the Next Step Today

Choosing the right partner for your packaging and material handling is a critical business decision. With our huge inventory, deep industry expertise, and unwavering commitment to customer success, we're confident we can help you hit your operational goals. It's time to stop overpaying for shipping and start optimizing your process.

Ready to see how the right packaging can transform your bottom line? You can explore our vast online inventory of shipping supplies to Shop Now, or take the first step toward a custom solution by getting a free, personalized quote from our experts.

To get started, Request a Quote online or Call (800) 326-4403 to speak directly with a member of our team. Let's build a better packaging solution together.

Got Questions About Shipping Box Dimensions? We've Got Answers.

When you're dealing with logistics day in and day out, the little details about shipping box dimensions can turn into big questions. Here are some straightforward answers to the queries we hear most often from warehouse managers and buyers, designed to help you make smarter, more cost-effective packaging decisions.

What Is the Standard Way to List Box Dimensions?

In the shipping world, the universal language is Length × Width × Height (L × W × H). Always. Just remember: Length is the longest side with a flap, Width is the shorter side with a flap, and Height is the distance from the floor to the top. Sticking to this simple formula every time prevents mix-ups and costly measurement errors down the line.

Are Box Dimensions for the Inside or Outside?

Great question. When you see dimensions on a product listing for a shipping box, they're almost always referring to the interior dimensions. This is the critical number you need—it tells you exactly how much usable space you have for your products. The exterior dimensions, which is what your carrier will use to calculate shipping costs, will be slightly larger because of the cardboard's thickness.

Why Did I Get Charged for a Higher Weight Than My Package Actually Weighed?

If you've ever seen this on an invoice, you've met dimensional (DIM) weight. It's a classic "gotcha" in logistics. Carriers will charge you for whichever is greater: the actual weight of your package on a scale, or its calculated DIM weight based on the box's size. Think of it this way—a big, lightweight box full of pillows still takes up a lot of valuable real estate on a truck, and carriers bill you for that space.

What Happens if My Box Is Slightly Oversized?

Even an inch can make a huge difference. Carriers are incredibly strict with their size and weight limits, and going over can trigger surprisingly high surcharges. In some cases, an oversized package might even be rejected outright, leading to frustrating and expensive delays. Always measure twice and round to the nearest inch, just as most carriers require.

Do I Really Need a Custom Box for My Products?

It depends. If your products have an unusual shape, are particularly fragile, or have a high value, a custom-sized box is often a smart investment. It offers far better protection and can dramatically lower your DIM weight costs by getting rid of all that empty, wasted space. For more standard items, however, a well-chosen stock box is usually the most economical path.

At Material Handling USA, we get that one size doesn't fit all. We offer a full range of standard and custom packaging solutions to match your exact operational needs. With competitive pricing, free design services, and the fastest shipping in the industry, we’re here to help you nail down your entire packaging strategy.

Request a Quote for a free consultation or give us a call at (800) 326-4403 to talk with an expert today.