When you're deciding between teardrop and structural pallet racking, the choice boils down to a core trade-off: flexibility versus brute strength.

Teardrop racking is known for its fast, boltless installation and easy adjustability, making it the go-to choice for most standard warehouse applications. On the other hand, structural racking is made from thicker, bolted steel, giving it superior durability and the muscle to handle heavy-duty, high-impact environments.

This guide will walk you through the key differences to help you make the right investment for your facility's unique demands.

Choosing Your Racking System: A High-Level Overview

Making the right call in the teardrop pallet rack vs. structural rack debate is a foundational decision that impacts your warehouse's efficiency and long-term safety. Understanding the fundamental differences between these two dominant systems is the first step toward an optimized storage solution.

This guide frames the critical trade-offs in load capacity, installation speed, flexibility, and overall cost. Nailing this choice from the start helps you avoid expensive future modifications and frustrating operational disruptions. While teardrop racks are praised for their modularity, structural systems are simply unmatched in their resilience.

If you want to go even deeper into warehouse storage, our comprehensive guide to selecting pallet rack for your warehouse is a great resource.

At a Glance: Teardrop Vs. Structural Pallet Racking

Sometimes the easiest way to see the difference is to put them side-by-side. This table cuts through the noise and highlights the main differentiators that warehouse managers and buyers need to weigh when looking at their options.

| Attribute | Teardrop Pallet Rack (Roll-Formed) | Structural Pallet Rack |

|---|---|---|

| Manufacturing | Made from cold roll-formed steel coils. | Constructed from hot-rolled structural steel. |

| Assembly | Boltless; beams clip into teardrop slots. | Fully bolted connections for maximum rigidity. |

| Installation | Fast and requires less specialized labor. | More labor-intensive and requires precise alignment. |

| Load Capacity | Suited for light to heavy loads; ideal for standard pallets. | Designed for heavy-duty and high-density loads. |

| Impact Resistance | More susceptible to damage from forklift impact. | Highly resistant to forklift damage and abuse. |

| Adjustability | Beams are easily moved in 2-inch increments. | Adjustments are possible but more time-consuming. |

| Initial Cost | Lower upfront investment. | Higher initial investment. |

| Common Uses | Retail, 3PL, and general warehousing. | Manufacturing, cold storage, and outdoor yards. |

As you can see, the choice isn't just about which is "better," but which is better for your specific job.

Aligning Racking With Operational Needs

Ultimately, the right choice between teardrop and structural racking comes down to your unique operational environment.

Teardrop systems, with their standardized design, offer incredible versatility. They're perfect for businesses with changing inventory or those needing to get a system up and running quickly. Their lower initial cost and ease of reconfiguration make them a popular choice for a massive range of standard applications.

Conversely, structural racking is engineered for permanence and durability. It's the definitive solution for facilities where heavy loads, frequent forklift traffic, and harsh conditions are the norm day in and day out. The investment in a structural system is an investment in long-term safety and minimal downtime from repairs.

To make sure your choice is a perfect fit, our team offers free, no-obligation layout and design services. Planning ahead with our experts can help you sidestep supply chain disruptions and lock in a faster installation timeline. Request a Quote today to get started.

Understanding Core Differences in Manufacturing and Design

To get to the bottom of the teardrop pallet rack vs structural rack debate, you have to look at how they’re made. The manufacturing process isn't just a technical footnote; it’s the origin story for each system's strengths and weaknesses. It dictates everything from how much weight it can hold to how much it costs you upfront.

This is why one rack system is perfect for a fast-moving retail warehouse, while the other is the only real choice for heavy-duty industrial work. It all starts with the steel.

The Cold Roll-Forming Process of Teardrop Racks

Teardrop racking starts its life as a coil of high-quality, flat sheet steel. At room temperature, this steel is fed through a series of precision rollers in a process called cold roll-forming. Each set of rollers methodically bends the steel, step-by-step, until it becomes the final shape for an upright or beam. It's an efficient method that produces strong, lightweight components with amazing consistency.

The most recognizable feature born from this process is the signature teardrop-shaped hole pattern punched into the uprights. This pattern is the key to the system's famous boltless connection—beams have small pins or clips that just slide into the teardrop holes and lock securely into place with gravity.

Key Takeaway: The cold roll-forming process is what gives teardrop racking its biggest advantages: lower material costs, lighter weight for easier shipping and handling, and a design built for rapid, tool-free assembly and adjustment.

This manufacturing efficiency translates directly into a lower initial investment and gives businesses the agility they need when inventory is constantly changing.

Hot-Rolled Steel and Bolted Design of Structural Racks

Structural pallet racking is a completely different animal. It’s made from steel that is heated to over 1,700°F before being rolled into shape. This hot-rolling process creates much thicker, denser steel components, usually in the form of structural C-channels. These channels become the backbone of the rack’s incredibly strong frames and beams.

There are no clips here. Structural rack components are fastened together with heavy-duty bolts. Beams are bolted directly onto the uprights, forging a rigid, unyielding connection that distributes massive loads and stands up to serious abuse. For a detailed breakdown of these heavy-duty components, check out our pallet rack specifications. Assembly is more methodical, but the result is a fortress-like structure built to last.

Material and Design: A Side-by-Side Comparison

The contrast between these two manufacturing philosophies is night and day. Seeing them side-by-side makes it clear which system is engineered for your specific environment.

| Feature | Teardrop (Roll-Formed) Racking | Structural Racking |

|---|---|---|

| Manufacturing Process | Cold roll-forming of steel coils. | Hot-rolling of structural steel C-channels. |

| Material Thickness | Thinner gauge steel, optimized for strength-to-weight ratio. | Thicker, denser steel for maximum durability. |

| Component Design | Features teardrop punch holes for clip-in connections. | Uses drilled holes for heavy-duty bolted connections. |

| System Rigidity | Relies on the interlocking fit of beams and uprights. | Achieves rigidity through tightly torqued bolts. |

| Repair Method | Damaged components are typically replaced entirely. | Sections can sometimes be repaired by welding (by a certified professional). |

Ultimately, your choice depends on what your operation throws at it. The precision and easy modularity of cold-formed teardrop racking is a smart, cost-effective solution for most standard warehousing needs. But for applications that demand uncompromising strength and the ability to withstand a tough environment, the hot-rolled, bolted construction of structural racking is the only way to go.

Getting this decision right is critical. Our team can provide a free layout and quote to make sure your choice perfectly matches your operational demands. Give us a call at (800) 326-4403 to talk about your project.

Evaluating Installation Speed And System Flexibility

Operational downtime is a massive cost for any business, and the time it takes to install or reconfigure your storage system hits your bottom line directly. When you stack up teardrop pallet rack vs. structural rack, the differences in assembly speed and long-term flexibility are dramatic. They can make or break your entire project timeline.

This is where teardrop racking really shines. Its biggest advantage is its incredibly fast, nearly tool-free assembly. Thanks to the signature boltless design, horizontal beams lock into the teardrop-shaped holes on the uprights and are secured with a simple safety clip. It’s a design choice that drastically cuts down on labor hours and overall setup time.

The Advantage of Boltless Assembly

The speed of teardrop rack installation makes it the go-to choice for facilities that need to get up and running yesterday or expect to reconfigure things often. Picture a 3PL warehouse bringing on a new client or a retail distribution center flipping its layout for seasonal inventory. Being able to add, remove, or adjust beam levels on the fly without calling in a specialized crew is a huge operational win.

This efficiency is so significant that it has driven massive adoption across the industry. In fact, teardrop systems can be installed about 50% faster than their structural counterparts—a direct result of that simple, boltless design.

A More Methodical Approach with Structural Racks

On the other hand, the bolted assembly of structural racks is a much more deliberate, labor-intensive affair. Every single connection has to be perfectly aligned, fitted with heavy-duty bolts, and torqued to precise specifications to get its full strength. What you trade in speed, you gain in brute stability and a permanent, rigid structure.

While it definitely takes longer to put together, that permanence is the core strength of structural racking. It’s built for environments where the layout is set in stone and the main concern is withstanding punishing loads and potential impacts for years on end.

Key Insight: Planning your racking needs well in advance is crucial. Smart managers who anticipate their growth get ahead of installation timelines and avoid the operational logjams that come from picking a system that doesn't match their facility's pace of change.

System Flexibility and Component Interchangeability

Beyond the initial setup, you have to think about long-term flexibility. Teardrop racking wins here, too. The teardrop punch-hole design has become such an industry standard that components from different manufacturers are often interchangeable. This is a game-changer when you need to source replacement parts or expand your system down the line, giving you more options and helping control maintenance costs.

Structural rack components, however, are typically proprietary. You’re locked into sourcing parts from the original supplier, which can limit your options and potentially increase costs.

For businesses that live and breathe speed, adaptability, and cost-effective installation, teardrop racking is the undisputed champion. For those who need maximum durability in a stable, predictable environment, the methodical installation of a structural system is an investment that pays off.

If you are planning a new layout or expansion, we can help you get ahead. Our team offers free layouts and designs with no obligation, ensuring you can plan your project timeline effectively. Contact Us or call (800) 326-4403 to start planning today.

Comparing Load Capacity And Forklift Impact Resistance

When you're choosing a racking system, two things matter more than anything else: how much weight it can hold and how well it stands up to the daily grind of a busy warehouse. In the teardrop pallet rack vs structural rack debate, this is where the differences really show. Getting this choice right directly impacts safety, how long your system lasts, and your bottom line.

The decision often boils down to the raw demands of your inventory and the intensity of your operation. While both are solid storage solutions, they are built for completely different levels of punishment.

A Data-Driven Look At Load Bearing Capabilities

For heavy-duty applications, structural racking is the undisputed champ, and the numbers make it obvious why. It's engineered from the ground up to handle serious weight.

Sure, structural pallet racks come with a higher price tag, but they deliver superior load capacity and durability that justify the investment. These bolted systems typically cost 20-30% more upfront than their roll-formed teardrop cousins. But here's what you get for that: structural load beams can handle anywhere from 3,200 to 12,000 pounds per pair, while roll-formed beams generally top out around 8,900 pounds.

The upright frames tell a similar story. Structural frames boast capacities between 35,200 and 51,000 pounds, blowing past what roll-formed systems can handle.

Key Insight: The real question isn't just "which one is stronger?" It's about matching the right capacity to your specific products. Spending extra on structural racking for lightweight goods is a waste of money, but trying to save a buck by using teardrop for heavy loads is a massive safety hazard.

This strength makes structural racking the only real option for storing dense, heavy materials like:

- Raw steel coils or stacks of lumber

- Automotive engines or heavy manufacturing dies

- Full pallets of beverages or bulk food products

If you're distributing pillows, teardrop racking is a perfect, cost-effective fit. But for a granite slab supplier, structural is non-negotiable. Our experts can help you calculate your exact load requirements with a free, no-obligation quote.

Superior Resistance To Forklift Impacts

Beyond just holding static weight, a rack’s ability to take a hit is critical for long-term safety and cost control. Forklift collisions are an unfortunate but common cause of rack failure. The thicker, hot-rolled steel and bolted connections of structural racking give it a built-in advantage in impact resistance.

The C-channel construction of a structural upright is fundamentally tougher than the open-back design of a typical roll-formed upright. When a forklift bumps into a structural column, it's far more likely to get a dent without compromising its integrity. A similar impact on a thinner, roll-formed column can cause it to buckle or twist, often leading to a catastrophic failure that requires replacing the whole section.

This resilience makes structural racking a smart investment in high-traffic areas, narrow-aisle setups, or any facility where forklift operators might be less experienced. The higher initial cost is frequently offset over time by lower repair bills and—most importantly—a safer work environment. While investing in good forklift pallet rack protection is always a smart move, starting with a stronger frame gives you an essential first line of defense.

Choosing the right system means having a clear picture of your daily operational risks. Our team can help you assess your facility's traffic patterns and impact potential to ensure your racking investment is built to last. Call us at (800) 326-4403 to talk about a custom solution.

Analyzing Initial Investment Vs. Total Cost Of Ownership

When you're making a major purchase decision, the budget is always a huge factor. It’s tempting to look at the quotes for teardrop pallet rack vs. structural rack and just focus on the upfront price tag. But the smartest investment comes from looking at the total cost of ownership (TCO), which gives you a much clearer financial picture over the long haul.

While teardrop systems almost always have a lower initial cost, several other factors influence what you actually spend over the system's life. Understanding these variables is the key to making a truly cost-effective choice that matches your day-to-day operational reality.

Upfront Purchase and Installation Costs

The initial quote is where the financial comparison starts. Roll-formed teardrop racking is less expensive to manufacture, which results in a lower price for the materials themselves.

Beyond the steel, installation labor is a significant chunk of the cost. Teardrop racking’s boltless, clip-in assembly means it can be installed up to 50% faster than structural racking. That speed directly translates to fewer labor hours and a smaller installation bill, making that initial cost gap even wider.

Structural racking demands a larger upfront investment. This is due to both its heavier, hot-rolled steel components and the more methodical, labor-intensive bolted assembly process.

Factoring in Repair, Maintenance, and Lifespan

This is where the financial story can take a turn. In a standard, low-traffic warehouse, a well-maintained teardrop system can offer an excellent return on your investment. But in tougher, busier environments, the math starts to change.

Structural racking’s superior durability means it doesn't get damaged as often, so it requires fewer repairs over its lifespan—especially in high-traffic areas. When a teardrop upright gets hit hard, it usually needs a full replacement. That means unloading the rack, disassembling the section, and putting in a new frame, which costs you in both materials and operational downtime.

A structural rack, on the other hand, is far more likely to shrug off an accidental impact with little more than a scratch. This incredible resilience minimizes ongoing maintenance expenses and prevents those costly interruptions to your workflow.

In demanding settings like cold storage, manufacturing plants, or busy distribution centers, the lower frequency of repairs for structural racking can eventually offset its higher initial price, resulting in a lower total cost of ownership over a decade or more.

Making a Financially Sound Decision

Choosing the most cost-effective system is about looking beyond that first invoice. You have to be honest about your operational intensity and project the likely costs of maintenance and potential replacements over the system's entire service life.

Overspending on a heavy-duty structural system just to store lightweight goods is an inefficient use of capital. On the flip side, underspending on a teardrop system for a punishing environment will inevitably lead to higher long-term costs from frequent repairs and, eventually, a full replacement.

The goal is to find that perfect balance for your specific needs. Our team specializes in helping you analyze these factors. We provide free, no-obligation layouts and designs, along with competitive pricing on both teardrop and structural systems. This ensures you can evaluate the complete financial picture and make the smartest investment for your facility.

Ready to see a detailed cost comparison for your specific application? Request a Quote online or call our experts at (800) 326-4403 for a transparent breakdown.

Making The Final Decision For Your Application

We've covered a lot of ground comparing teardrop and structural racking. Now, it comes down to applying all that information to your specific operation. There isn't a single "best" choice—only the system that’s better engineered for your inventory, your environment, and your budget.

The right decision comes from understanding where each system truly shines. One offers agility and cost-efficiency; the other delivers uncompromising strength and durability.

Mapping Racking Systems To Real-World Applications

For the majority of modern logistics and distribution centers, teardrop racking is the clear front-runner. Its blend of flexibility and lower upfront cost makes it the default solution for facilities handling standard pallet loads in a dynamic environment.

It’s the perfect fit for places like:

- E-commerce Fulfillment Centers: Product lines are constantly changing, and layouts must adapt on the fly to accommodate new SKUs.

- Third-Party Logistics (3PL) Warehouses: These facilities need to be chameleons, adapting to a diverse range of client products with wildly different storage needs.

- Retail Distribution Centers: Handling consumer goods on standard pallets means quick reconfiguration for seasonal inventory is a massive competitive advantage. Our case study on a pillow distributor is a textbook example of this in action.

On the other hand, structural racking becomes non-negotiable when the operational demands get serious. Its heavy-duty, bolted construction is built from the ground up for the toughest conditions where safety and long-term durability are everything.

You’ll find it’s the only viable solution for:

- Manufacturing Facilities: Storing heavy raw materials, massive dies, or bulky finished goods that would overwhelm lesser racking.

- Cold Storage and Freezer Warehouses: In sub-zero temperatures, steel can become more brittle. The added mass and impact resistance of structural rack is crucial.

- Lumber Yards and Building Material Suppliers: These operations deal with exceptionally heavy, uneven, or awkward loads that demand a robust frame.

- Seismic Zones: In areas prone to earthquakes or in any facility with constant, heavy forklift traffic, the integrity of your racking system simply cannot be compromised.

A Final Checklist for Your Decision

To bring it all home, walk through these five critical questions about your operation:

- Inventory Profile: What’s the absolute maximum weight of your heaviest pallet load? Are your products uniform, or do the dimensions vary wildly?

- Operational Intensity: How many forklifts are running in your aisles every day? Is the risk of accidental impact low, moderate, or high? Be honest.

- Future Flexibility: How likely is it that you'll need to tear down and reconfigure your warehouse layout in the next five years?

- Environmental Conditions: Is the racking going indoors, outdoors, or into a freezer or cooler?

- Budgeting Approach: Is minimizing the initial investment your top priority, or are you focused on the long-term total cost of ownership?

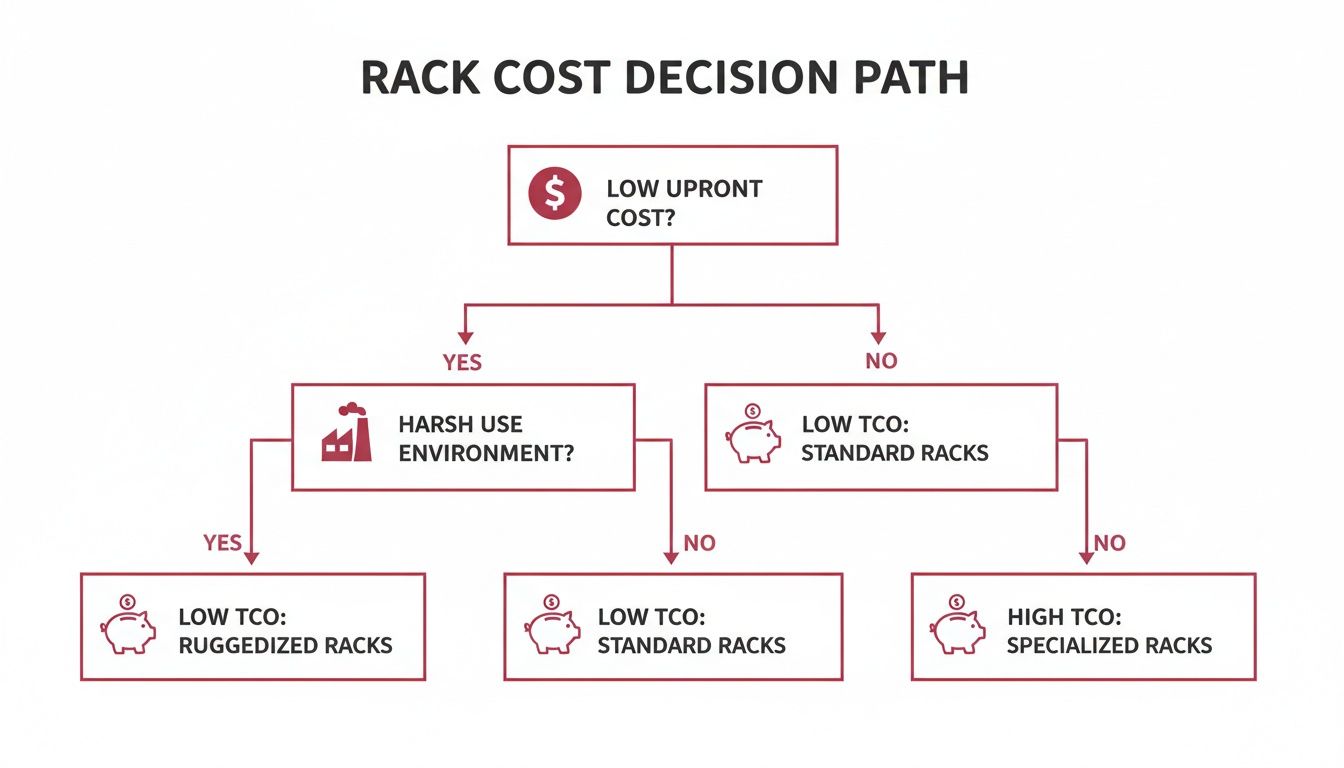

This decision tree gives you a clear visual for how the financial side of things plays out based on your environment.

As the chart shows, while teardrop racking nearly always has a lower upfront cost, structural racking often delivers a much lower total cost of ownership when used in the harsh, high-traffic environments it was designed for.

While this guide gives you a solid foundation, the best solution always comes from an expert consultation. We highly recommend you take advantage of our free, no-obligation pallet rack design services for a custom layout and a precise quote. With many businesses finalizing their expansion plans, acting now will get you priority access to our design team and secure a faster installation timeline.

Contact Us or call (800) 326-4403 to make sure your investment is perfectly engineered to hit your operational goals.

Frequently Asked Questions

When you're trying to choose between teardrop and structural racking, a lot of practical questions come up. We hear them all the time. Let's tackle the most common ones to clear up any confusion about what will work best for your operation.

Can I Mix Teardrop And Structural Rack Components?

No, you cannot mix components from these two systems. We strongly advise against it for critical safety reasons. Teardrop and structural racks are built differently from the ground up—they have unique connection methods, different steel thicknesses, and completely separate load ratings. Trying to force them together creates an unstable, dangerous structure. It’s a major safety code violation that puts both your people and your inventory at serious risk. If you need to add on to your current racking, the first step is to correctly identify what you have. Our team can help you figure that out to make sure you get parts that are 100% compatible.

What Industries Almost Always Require Structural Racking?

Structural racking is the go-to standard for any industry dealing with exceptionally heavy loads or tough working conditions. In certain environments, its raw strength and durability are non-negotiable.

You'll almost always find structural racking in:

- Lumber yards and steel service centers where they’re handling incredibly dense and heavy materials.

- Outdoor storage applications. If your racks are exposed to rain, snow, and sun, you need the resilience of structural steel.

- Freezer or cold storage warehouses. The cold can make steel more brittle, so the impact resistance of a thicker, bolted system is critical.

- Seismic zones. Those heavy-duty bolted connections provide the rigidity needed to stand up to ground movement.

How Do I Identify My Existing Pallet Racking Type?

The quickest way to tell what you have is to get up close and look at how the beams connect to the upright frames. The connection point tells you everything.

Look at the holes and the fasteners. Teardrop racks have distinct, punched teardrop-shaped holes running up the face of the upright. Beams connect with small, built-in clips that drop into these holes. Structural racks use basic round or square holes, and the beams are locked into place with heavy-duty bolts and nuts.

You'll also notice that structural components are visibly thicker and heavier, which is a dead giveaway of its rugged design.

Which System Offers More Customization?

Both systems are highly customizable, but they offer flexibility in different ways. It really depends on what you need to customize.

Teardrop racking's biggest advantage is its flexibility for beam height adjustments. You can move the beams up or down in 2-inch increments easily, often without any tools. This is perfect for operations where your product sizes change frequently and you constantly need to reconfigure your storage heights.

Structural racking, on the other hand, is customized for brute strength and durability. It can be engineered from the ground up with different steel gauges and reinforcements to handle extreme weight requirements. If you need a rack system engineered to hold massive loads safely, structural offers more customization for pure capacity.

Conclusion: Partner with the Experts for the Right Solution

Choosing between teardrop and structural pallet racking is a significant decision that impacts your warehouse’s efficiency, safety, and budget for years to come. Teardrop racking offers unparalleled flexibility and cost-effectiveness for standard applications, while structural racking provides the uncompromising strength needed for heavy-duty and harsh environments.

By evaluating your specific load requirements, operational intensity, and long-term costs, you can make an informed choice that supports your business goals. But you don't have to make this decision alone.

At Material Handling USA, we pride ourselves on competitive pricing, the fastest shipping in the industry, and providing quality materials you can trust. Let our experts provide a free, no-obligation layout and design to ensure your racking solution is perfectly tailored to your needs.

Ready to optimize your warehouse? Request a Quote today or call us at (800) 326-4403 for a free consultation.