Warehouse racking uprights are the vertical steel columns that make up the frame of your entire storage system. They are the foundational support structures that bear the full weight of your inventory, making their strength and stability absolutely critical for a safe, efficient warehouse. As a manager or buyer, understanding these components is the first step toward a smart investment.

The Role of Uprights in Your Racking System

Think of warehouse racking uprights as the backbone of your storage. Just like a strong skeleton supports a body, these frames support every pallet, box, and product you store.

A weak or improperly chosen upright system jeopardizes not just your inventory but also the safety of your team and the efficiency of your workflow. Getting this foundational choice right from the start is the first step in preventing costly accidents and unlocking your operation's full potential.

The demand for robust racking solutions is growing, thanks to the non stop growth of e commerce and logistics. The global pallet racking market is projected to grow from USD 12.27 billion in 2025 to USD 27.34 billion by 2034. This trend highlights just how much modern supply chains rely on high quality components like warehouse racking uprights.

Core Components of an Upright Frame

An upright frame isn't just one piece of steel. It's a precisely engineered assembly built for maximum strength and stability. Understanding its individual parts helps you appreciate why quality materials and design are so important.

- Columns: These are the two main vertical posts that face the aisle. They feature the connection points, often teardrop shaped holes, where you lock in the horizontal beams.

- Bracing: This is the web of horizontal and diagonal steel struts welded between the two columns. Bracing is what gives the frame its rigidity and stops it from twisting or swaying under a heavy load.

- Footplates: Also called baseplates, these are the flat steel plates welded to the bottom of each column. They spread the entire load across the concrete floor and provide anchor points to secure the frame.

Together, these components create a single, durable frame that transfers the full weight of your stored goods safely to the ground. A well designed upright is the difference between a reliable storage bay and a potential disaster.

By starting with a solid foundation, you set your entire operation up for success. We offer a full range of pallet rack systems and can help you design the perfect layout for your facility. Planning your racking system with an expert ensures you get a solution that is not only safe but also perfectly matched to your inventory and workflow.

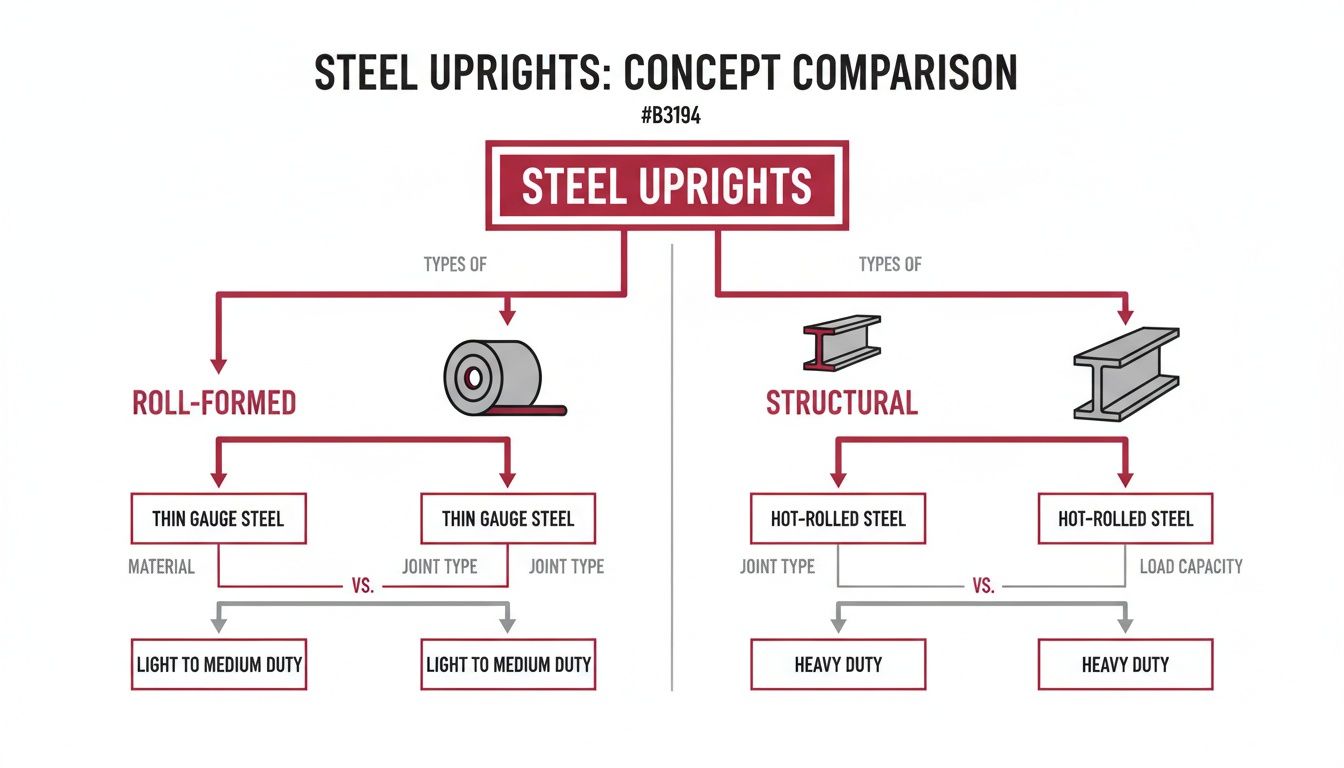

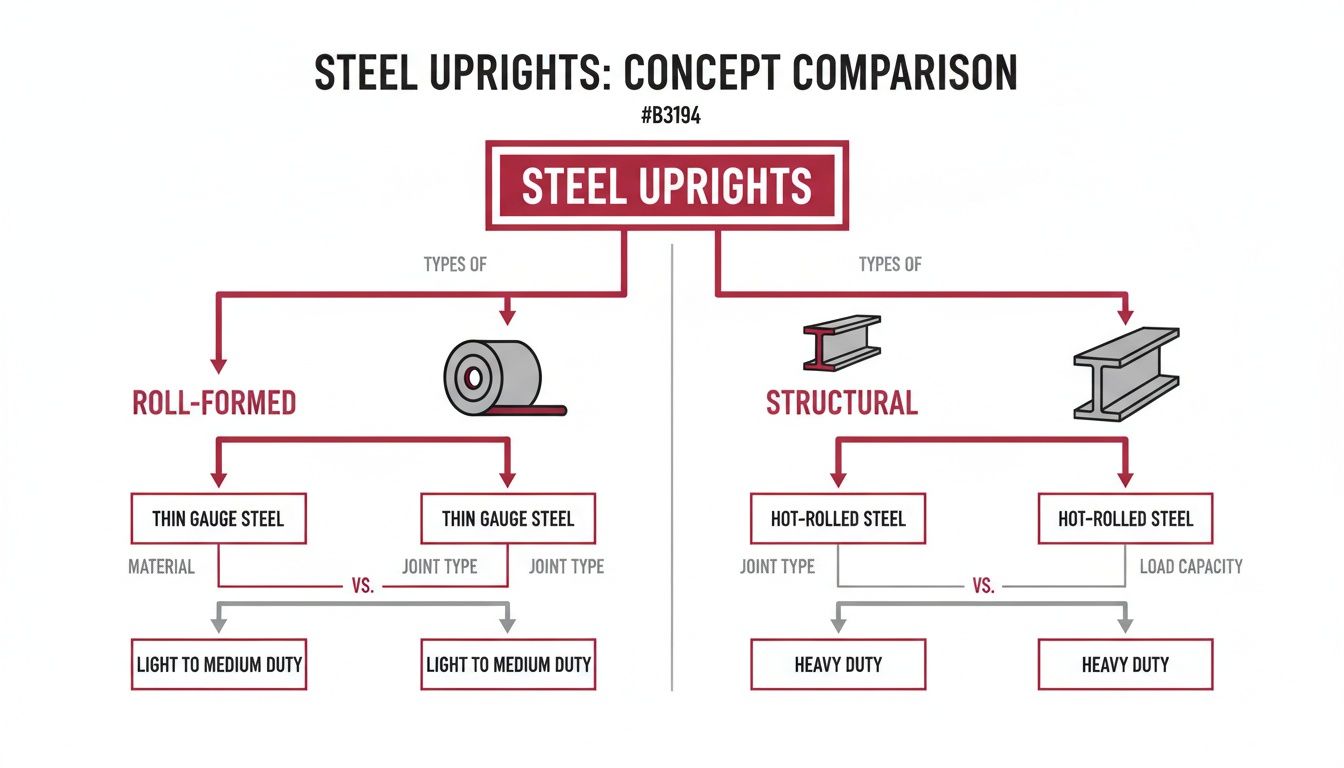

Comparing Roll Formed and Structural Steel Uprights

When you're choosing warehouse racking, one of the first big decisions you'll face is the type of upright to use: roll formed or structural steel. This isn't just a minor detail; it fundamentally impacts your system's cost, durability, and suitability for your specific operation. Getting this choice right is key to a smart, long term investment.

Roll formed uprights are made using a cold rolling process. A long, flat coil of steel is fed through a series of rollers that gradually bend and shape it into the final upright profile. It’s an efficient process that uses less material, which is why roll formed racking is often the more budget friendly option.

On the other hand, structural steel uprights are hot rolled. The steel is heated to high temperatures before being shaped into classic I beam or C channel forms. This method creates a much thicker, denser, and tougher product built for raw strength and serious impact resistance.

Ideal Applications for Each Type

The best choice boils down to your day to day operations. A fast paced distribution center buzzing with forklift traffic has completely different demands than a quiet retail stockroom.

Roll Formed Uprights are best for:

- Retail and E-commerce: A perfect fit for environments with lighter loads and less interaction with heavy machinery.

- General Warehousing: The go to, cost effective solution for standard pallet storage where the risk of major impacts is low.

- High Density Storage: Their lighter profile can be an advantage in systems like carton flow or specialized shelving.

Structural Steel Uprights are necessary for:

- Cold Storage and Freezers: In freezing temperatures where steel can become brittle, the sheer toughness of structural steel is a non negotiable safety feature.

- Heavy Industrial Settings: When you're storing heavy dies, massive coils, or raw materials, you need a rack that can take a hit and keep on standing.

- Fast Paced Distribution Centers: In high traffic aisles where forklift collisions are a constant threat, structural steel is your best defense.

Understanding Column Styles and Compatibility

Beyond just the material, the style of the upright column, specifically its hole pattern, is what determines which beams you can use. The hole pattern is like the upright’s "language," and it has to match the connectors on your beams perfectly.

By far, the most common style in the U.S. is teardrop. You can spot it by its distinctive teardrop shaped holes. This design is incredibly versatile because dozens of manufacturers produce compatible beams, making it a breeze to find replacement parts or expand your system down the road. Better yet, the design allows beams to be installed and adjusted quickly, often without any tools.

Another popular, though less common, style is keystone, which uses a keyhole or rectangular punch. It’s a solid design, but its limited compatibility means you have to be much more careful when sourcing parts.

Choosing a common pattern like teardrop can be a strategic advantage. As facilities grow and needs change, having the flexibility to easily source compatible components prevents costly system replacements and minimizes downtime.

Making the Right Decision for Your Operation

The choice between roll formed and structural steel isn't just about the initial price tag; it's about long term value and safety. Weighing the trade offs will make the best path forward clear. A quick side by side comparison can help clarify which upright material is the right fit for your warehouse needs.

Roll Formed vs. Structural Steel Uprights Comparison

| Feature | Roll Formed Steel Uprights | Structural Steel Uprights |

|---|---|---|

| Manufacturing | Cold rolled from steel coils | Hot rolled into structural shapes |

| Initial Cost | Lower | Higher |

| Durability | Good for standard use | Exceptional impact resistance |

| Adjustability | Highly adjustable (2" increments) | Less adjustable |

| Repairs | Often requires replacement | Can sometimes be repaired in place |

| Best For | Light to medium duty applications | Heavy duty, high impact environments |

Ultimately, you have to take a hard look at what your warehouse demands. If your operation involves heavy loads and constant forklift activity, the higher upfront cost of structural steel is a wise investment in safety and longevity. For many standard warehousing applications, however, the flexibility and competitive pricing of roll formed uprights provide an excellent, reliable solution.

Unsure which upright type is right for your facility? The sooner you consult an expert, the better your project timeline will be. Call our team at 800-326-4403 for a free consultation to ensure you get the perfect fit.

How to Read Upright Specifications and Capacity

Looking at a technical spec sheet for warehouse racking can feel overwhelming. It's a wall of numbers, charts, and jargon. But once you know what to look for, that intimidating document becomes your single best tool for making a smart, safe, and efficient purchase.

Think of it this way: every number on that sheet tells part of the story. The upright's height, its depth, and the gauge (or thickness) of the steel aren't just random measurements. They work together to determine the most critical factor of all: load capacity. A taller upright might need thicker steel to stay rigid, while a deeper one can better resist tipping. It's all connected.

The All Important Load Capacity

At its core, load capacity is the maximum weight an upright frame can safely hold. This isn't a suggestion; it's a non negotiable limit engineered to prevent system failure and keep your team safe. Pushing past this limit compromises the entire rack bay, creating a serious risk of collapse.

Manufacturers don't just guess these numbers. They arrive at them through rigorous engineering calculations and physical stress tests that account for the upright's specific design, steel thickness, and bracing pattern. These ratings are the absolute ceiling.

This focus on engineered safety is a big deal. The market for conventional pallet racks, with uprights as their backbone, is part of a global USD 2.776 billion market in 2025, which is expected to climb to USD 3.435 billion by 2034. The U.S. market alone, which makes up a big piece of North America's 37.10% global share, was valued at USD 4.8 billion in 2024. This growth is all about facilities relying on precisely engineered components that work together flawlessly.

Why Vertical Beam Spacing Changes Everything

One of the most overlooked, and most critical, factors affecting an upright's true capacity is the vertical distance between your beams. It's not a fixed number; it changes based on your layout.

Key Takeaway: The farther apart your beams are vertically, the less weight the upright can support.

Imagine the horizontal beams as support braces for the vertical columns. When they're close together, they keep the columns from bowing or buckling under a heavy load. But as you spread the beams farther apart to fit taller pallets, you create longer unsupported sections of the upright. This reduces its strength and, consequently, its safe load capacity.

This relationship is so important that manufacturers publish detailed capacity charts for every upright model they sell, showing you exactly how the capacity decreases as beam spacing increases. For a closer look at this, check out our in depth guide to pallet rack specifications.

The type of steel used also plays a massive role in capacity, as this image clearly shows.

You can see how the lighter, more common roll formed steel is perfect for most standard applications, while the beefy, hot rolled I beam design of structural steel is built for the toughest, heaviest duty jobs.

When Seismic Ratings Are Non Negotiable

Beyond the standard load capacity, seismic ratings are another crucial spec, especially if your facility is in an earthquake prone area. These aren't just "upgrades"; local building codes often mandate them as a legal requirement to protect both people and inventory.

A seismically rated upright frame is engineered differently from a standard one. Here’s what you’ll typically find:

- Thicker Steel: The columns and bracing are often made from a heavier gauge steel to handle lateral forces.

- Larger Footplates: The base plates that connect to the floor are oversized for a more robust anchor point.

- Specialized Anchoring: Seismic systems demand specific types, patterns, and depths of anchors to resist ground motion.

Figuring out if you need a seismic rating should be one of the very first steps in your design process. Bringing in experts early on can save you from major headaches and costly redesigns down the road. Our team can help you sort through the local codes to ensure your system is 100% compliant from day one.

Your Checklist for Selecting the Right Uprights

Picking the right warehouse racking uprights can feel like solving a complex puzzle. Get one piece wrong, and the whole system could be compromised. But with a methodical approach, it becomes a straightforward process that saves you from costly mistakes and frustrating delays. A little thoughtful planning today prevents headaches tomorrow.

The first step is to stop guessing and start measuring. You need to gather the hard numbers and operational data that will become the blueprint for your entire racking system.

Essential Pre Purchase Assessments

Before you even look at a single product, you need to know your physical space and the inventory that will live in it. These foundational details are non negotiable and will immediately narrow your options to the solutions that will actually work.

- Warehouse Clear Height: Measure the distance from the floor to the lowest hanging object in your ceiling, like sprinkler heads, lighting fixtures, or roof beams. This number is your absolute maximum upright height.

- Pallet Dimensions and Weight: Document the length, width, and height of your typical loaded pallet. More importantly, you must know the maximum weight of your heaviest pallet. This single number is the key to determining the load capacity you'll need.

- Forklift Specifications: Your forklifts determine your aisle width. Know their required turning radius, because that measurement dictates how much space you need between rows for safe and efficient operation.

System and Compatibility Checks

With your core data in hand, it's time to zoom in on the racking components themselves. Skipping these steps is a common mistake that can lead to mismatched parts or a failed inspection.

A common pitfall is assuming all racking components are interchangeable. Verifying compatibility with existing systems before you buy is essential to prevent creating an unsafe, hybrid rack that violates safety standards and voids warranties.

This is the perfect time to bring in experts for a free layout design. Getting a professional involved early helps nail down project timelines by spotting potential problems long before they can turn into expensive installation delays.

Final Verification and Planning Checklist

This is your final check. Running through this list ensures every logistical and regulatory box is ticked before you finalize your order.

- Define Aisle Requirements: Based on your forklift specs, lock in the minimum aisle width. Will you use a wide aisle for standard forklifts or a very narrow aisle (VNA) that requires specialized equipment?

- Confirm Component Compatibility: If you’re adding to an existing system, triple check that the new uprights and beams use the exact same connection style (e.g., teardrop) as your current setup.

- Evaluate Floor and Slab Condition: Your concrete slab has to support the immense point loads from the upright footplates. Make sure it's in good condition and, if possible, have the slab's PSI rating on hand.

- Review Local Building Codes: Every municipality is different. Check with your local building authority for specific seismic requirements or other codes that apply to pallet racking installations in your area.

- Plan for Accessories: Don't treat safety as an afterthought. Factor in necessary accessories like column protectors, end of aisle guards, and safety netting right from the start.

By working through this checklist, you’re not just buying racking; you’re building a comprehensive plan that guarantees a successful purchase and a smooth installation.

Ready to start designing your ideal storage solution? Our in stock warehouse racking uprights ship faster than anyone in the industry, and our team is ready to help. Shop Now or Contact Us for your free, no obligation layout and quote.

Best Practices for Upright Installation and Maintenance

Even the most perfectly engineered racking frame can become a liability if it's not installed or maintained correctly. The strength of your uprights is only as good as the work that goes into setting them up. Proper procedures aren't just suggestions; they are the bedrock practices that protect your inventory, your facility, and most importantly, your people.

Getting the installation right from the start is the single best way to prevent future problems. It all begins with the ground floor. A professional installation always starts by making sure the warehouse floor is level and strong enough to handle the immense point loads the racking will create. Even a minor dip in the concrete can throw off the stability of an entire bay.

Critical Installation Steps

A safe, stable racking system is built on precision. Before a single beam is attached, each frame must be perfectly plumb and level, both front to back and side to side. This meticulous alignment is what guarantees that weight is distributed exactly as the engineers planned.

Anchoring the system down is just as crucial. Using the right type and size of anchor bolt for your concrete slab's thickness isn't negotiable. The anchor is what keeps the whole structure from shifting, swaying, or tipping over from a heavy load or an accidental bump from a forklift.

Long Term Maintenance and Inspection

Once your racking is up and running, a proactive maintenance plan is your best defense against daily wear and tear. Damage is rarely a single, catastrophic event; it’s usually the result of small dings and stresses that add up over time. A simple and consistent inspection routine can catch these issues before they become dangerous failures.

Establishing a clear protocol for inspection, reporting, and repair is one of the most effective ways to extend the life of your racking system and ensure a safe working environment. It shifts your approach from reactive to proactive.

Beyond just the racking itself, smart warehouse organization tips play a huge role in operational success. A well organized space naturally cuts down on the risk of accidental impacts and makes regular inspections much easier to carry out.

As warehouse operations expand worldwide, the need for reliable racking is growing. The Asia Pacific region, for instance, now holds over 45% of the global market share for warehouse racking. Here in North America, the reliability of quality warehouse racking uprights is a direct factor in controlling long term operational costs.

A Practical Inspection Checklist

Regular walk throughs are the heart of any solid maintenance plan. Empower your team to spot and report problems with a straightforward checklist.

- Check for Obvious Damage: Scan the upright columns for any dents, bends, or creases. Pay close attention to the bottom few feet, as this is the most common impact zone for forklifts.

- Inspect Bracing: Make sure all horizontal and diagonal bracing is straight and securely attached. A single twisted or broken brace compromises the entire frame's integrity.

- Confirm Hardware Security: Double check that all anchors are tight against the footplate. Also confirm that all beam safety clips are properly engaged.

- Look for Corrosion: Check for any rust, especially at the base of the uprights or in areas with high humidity. Corrosion can slowly weaken the steel.

For a deeper dive, our article on how to keep warehouse racking safe offers even more expert advice. Protecting your investment starts with a commitment to these best practices.

Protect your investment and your people. Contact Us to discuss your installation or maintenance needs, or call 800-326-4403 for a free consultation.

Tying It All Together: From Uprights to Operations

We've covered a lot, from the basics of what a racking upright is to the details of engineering, installation, and long term care. Think of your uprights as the skeleton of your warehouse. An investment in the right ones isn't just another line item on a purchase order; it's the foundational decision that dictates your facility's safety, efficiency, and ability to grow.

When you get the specifications right, insist on professional installation, and commit to regular maintenance, you're building a high performance storage environment from the ground up. This knowledge is your first step toward a stronger, more reliable operation.

Putting This Knowledge to Work

Theory is great, but what's next? It's time to apply these principles to your own facility. Our team is here to help you turn your operational needs into a concrete plan. We offer free, no obligation quotes and professional layout designs to get you started. With competitive pricing and the fastest shipping in the industry, your project can keep moving forward without a hitch.

Getting our design experts involved early is a strategic advantage. It's the best way to sidestep common operational bottlenecks and ensures your project gets done smoother and faster, putting your business on the path to greater efficiency right away.

Taking a proactive stance on your warehouse infrastructure is one of the smartest moves any manager can make. It protects your inventory, keeps your team safe, and builds a more resilient supply chain. Don't let uncertainty about specs or layouts stall your progress. We're here to offer the clarity and support you need to build a better, stronger warehouse foundation.

Let's start building that better warehouse together. Request your free quote and layout design from our experts today, or give us a call at 800-326-4403 to get started.

Common Questions About Racking Uprights

Once you get past the basics, real world questions start popping up. We get calls about these specific scenarios all the time from warehouse managers trying to make the right call. Here are some clear, straightforward answers to the most common questions we hear.

Can I Mix Uprights and Beams from Different Brands?

This is a big one, and the short answer is no. It’s a practice we strongly advise against because it’s almost always unsafe.

Every manufacturer has its own proprietary engineering and connection design. The specific shape and spacing of the teardrop or keystone punch holes aren't universal. Trying to force a beam from one brand into an upright from another often results in a loose, unstable connection, a risk you can't afford to take. This mismatch can compromise the safety of the entire system.

Mixing and matching will also instantly void manufacturer warranties and can get you flagged on a safety inspection. For guaranteed stability and peace of mind, stick with components from the same brand. If you’re trying to add to an existing system and aren't sure what you have, give us a call at Material Handling USA. We can help you identify it and find a truly compatible solution.

How Do I Know If an Upright Is Damaged?

The best defense is a good offense. Regular visual inspections are your number one tool for catching damage before it leads to a catastrophic failure. Make a habit of walking your rows and paying special attention to the bottom few feet of the uprights, the prime area for forklift impacts.

Here are the key signs of damage you need to look for:

- Visible Deformations: Look for any dents, dings, creases, or bends in the steel column. Don't ignore them, even if they look minor.

- Bracing Issues: Check the horizontal and diagonal bracing between the two columns. If any pieces are twisted, bent, or broken, that's a red flag.

- Cracks or Corrosion: Scan for any cracks in the steel itself or signs of rust, especially around the baseplate where it's anchored to the floor and near any welds.

Even a small dent can dramatically weaken an upright's ability to hold its rated capacity. If you spot any of these issues, the protocol is simple: immediately unload the entire bay, rope it off so no one uses it, and call in a professional to assess whether it needs to be repaired or replaced.

What Is the Difference Between an Upright and a Frame?

You'll hear people use these terms interchangeably, but in the world of pallet racking, they mean slightly different things.

Technically, an upright is just one of the single vertical columns.

A frame is the complete unit that you actually order and install. It’s a factory welded assembly made of two upright columns connected by a web of horizontal and diagonal steel bracing. So, when you buy "racking uprights," you're really purchasing the entire frame assembly, which is the foundational structure that gets anchored to the floor and holds up all your beams.

How Does the Height to Depth Ratio Affect Stability?

This is one of the most critical safety calculations in any rack system design, and it’s all about preventing your rack from tipping over. There’s a simple rule that safety codes are built around: if the height of your top beam level is more than six times the depth of your upright frame (a 6:1 ratio), the rack is considered unstable on its own.

For example, with a standard 42 inch deep frame, the top of your highest beam level shouldn't be more than 252 inches (or 21 feet) off the ground. Any higher, and you have a stability problem.

When a rack system exceeds this 6:1 ratio, it becomes dangerously top heavy. The fix is to provide external support by either anchoring the row to a structural wall or connecting it back to back to another row of racking with components called row spacers. Our design experts always run this calculation to ensure every layout we provide is safe and fully compliant from day one.

At Material Handling USA, we don't just sell parts; we provide the expertise to help you build a safe, efficient, and reliable storage system. If you have more questions or you're ready to get a plan in motion, our team is here to help.

Call 800-326-4403 or Request a Quote for your free, no obligation design today.