When it comes down to the boltless shelving vs welded shelving debate, the core difference is simple: flexibility versus permanence. Boltless shelving is all about adaptability, perfect for dynamic environments where needs change. On the other hand, welded shelving delivers maximum rigidity and brute strength for heavy-duty, long-term storage.

Picking the right shelving isn’t just about holding items; it’s a strategic decision that impacts your operational efficiency, labor costs, and your ability to adapt. This guide offers a detailed, side-by-side comparison to help you decide if the adaptability of boltless shelving or the raw power of welded is the right move for your facility.

If you're in the early stages of a major project, your storage system is a foundational choice. Here at Material Handling USA, our focus is making sure you’re equipped with the right solution from day one. We offer free layouts and designs with no obligation to help you plan effectively.

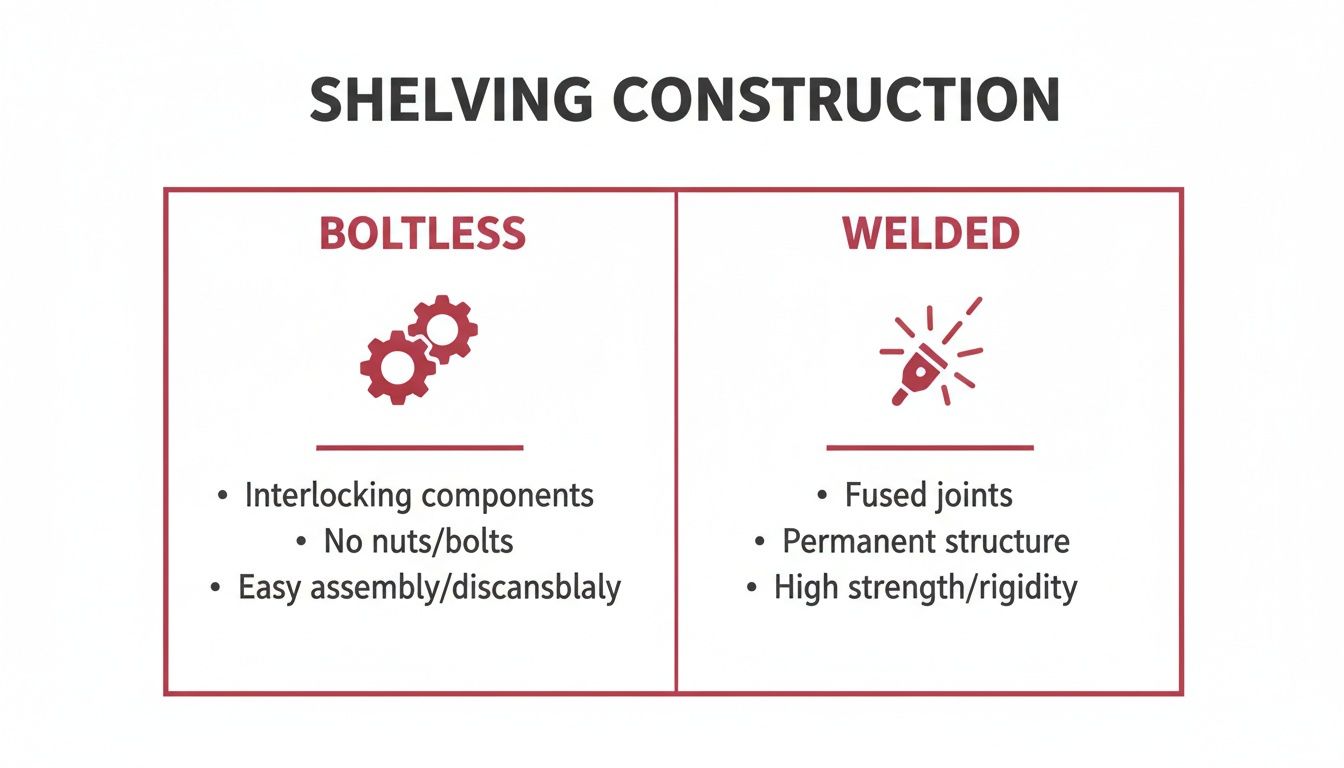

Understanding the Fundamental Differences

Before diving into specifications, let's establish the basics. Boltless shelving is built for speed—quick to assemble and easy to reconfigure without a toolbox. Welded shelving is all about brute strength and a fixed structure.

Quick Comparison: Boltless vs Welded Shelving

To get a quick handle on which system might fit your needs, this table breaks down the essential differences at a glance.

| Attribute | Boltless Shelving | Welded Shelving |

|---|---|---|

| Assembly | Fast, tool-free setup using rivets or tabs. | Arrives fully assembled or requires professional installation. |

| Adjustability | Highly flexible; shelves easily reconfigured. | Fixed and permanent; shelves cannot be adjusted. |

| Load Capacity | Good to excellent; suitable for most commercial needs. | Excellent to superior; designed for extreme loads. |

| Best For | Evolving inventories, retail, pick-and-pack areas. | Heavy industrial parts, permanent archives, bulk storage. |

| Mobility | Can be disassembled and moved easily. | Difficult and costly to relocate. |

Ultimately, choosing the right system means matching its strengths to your daily operations. If you’re dealing with constantly changing SKUs or anticipate layout adjustments, exploring versatile options like our selection of boltless shelving is a smart move.

With project timelines getting tighter, many operations managers find that the time saved during installation is a massive advantage. Getting your storage up and running faster means your facility becomes operational sooner.

The Core Design: Boltless vs. Welded Shelving

To make the right call between boltless and welded shelving, you have to understand how each system is built. Their core design philosophy dictates everything from assembly speed and flexibility to long-term durability and weight capacity.

Boltless shelving uses smart, interlocking designs that eliminate traditional nuts and bolts. This approach allows for rapid assembly, often without tools, and makes future shelf height adjustments just as quick. On the flip side, welded shelving is defined by its permanent construction, where every joint is fused into a single, unyielding unit.

The Engineering Behind Boltless Shelving

The genius of boltless shelving is its simple efficiency. Components are engineered to lock together securely, usually with a rivet and keyhole system.

The upright posts have keyholes, and the horizontal beams feature matching rivets. In most cases, a simple rubber mallet is the only tool you need to tap the rivets into place. This creates a tight, secure connection that uses gravity and the weight of your inventory to become even more stable. It's a design that's not just fast to assemble but also incredibly intuitive. You can dive deeper into the specific parts and advantages of our boltless shelving systems.

Welded Shelving Construction: A Permanent Solution

Welded shelving takes the opposite approach. It prioritizes absolute strength and permanence, sacrificing adjustability for raw power. During manufacturing, every shelf, post, and brace is professionally welded at the joints, creating a monolithic structure that arrives as one solid piece.

This process delivers exceptional rigidity and stability, which is why it's the go-to choice for extreme load requirements and tough industrial environments. The welded connections distribute stress evenly across the entire frame, eliminating potential weak points.

Key Takeaway: The primary design difference is modularity vs. permanence. Boltless systems are designed to be assembled and reconfigured, while welded units are built as a single, fixed piece for maximum structural integrity.

For managers planning new layouts or facility upgrades, the faster installation timelines of boltless systems often mean projects can be completed ahead of schedule. This allows operations to resume more quickly, providing a clear return on investment. Our team offers free layouts and designs with no obligation. Request a Quote to see how we can optimize your space.

A Detailed Comparison of Key Performance Metrics

A real side-by-side comparison is where you make a smart investment. The boltless shelving vs welded shelving debate comes down to how each system performs in your day-to-day operations. This breakdown covers the critical factors that will impact your budget, timeline, and overall efficiency.

Load Capacity and Durability

The first question any manager asks is: how much can it hold?

When it comes to raw strength, welded shelving is the undisputed champion. Its fused joints create a single, monolithic structure that handles extreme loads, making it the go-to choice for storing heavy industrial parts or dense materials.

That said, modern boltless shelving is engineered to be incredibly tough. Heavy-duty systems can easily support thousands of pounds per shelf. For the vast majority of warehouse and commercial uses—from e-commerce fulfillment centers to auto parts stockrooms—a high-quality boltless system provides more than enough strength, striking a great balance between power and practicality.

Assembly and Installation Speed

Time is money. The difference in installation speed between these two systems is one of the biggest differentiators.

Boltless shelving is built for speed. Its components lock together with just a rubber mallet, meaning a small team can assemble entire rows in a fraction of the time required for other systems. This reduces labor costs and project timelines, getting your storage areas operational faster.

Welded shelving usually arrives pre-assembled. While that sounds easy, it means you'll need forklifts or other heavy equipment to move each unit into place. Maneuvering these bulky units can be slow and requires careful planning, especially in tight quarters.

Flexibility and Reconfiguration

Business needs change. Your storage system's ability to adapt is a huge factor in its long-term value.

This is where boltless shelving truly shines. You can adjust shelf heights in minutes to fit different product sizes. Need to rethink your layout? You can disassemble the system and rebuild it elsewhere with minimal fuss. This modularity is essential for any business that needs to stay agile and is also a key feature of our mobile shelving systems.

Welded shelving is static. Once installed, it's there for good. The shelf heights are fixed, and moving a unit is a major project. Its permanence provides incredible stability but offers zero room to adapt as your storage needs evolve.

Key Insight: Choosing boltless shelving is an investment in operational agility. Its ability to be reconfigured quickly means your storage can evolve with your business, preventing costly downtime and major overhauls.

Total Cost of Ownership

Looking beyond the initial price tag is essential. Total cost of ownership includes the purchase price, installation labor, and long-term value.

- Upfront Cost: Welded shelving often carries a higher initial price due to a more intensive manufacturing process.

- Installation Cost: Boltless shelving is the clear winner. You save significantly on labor hours since you don't need specialized tools or heavy equipment.

- Lifecycle Value: The value of boltless shelving is its adaptability, which saves you from buying new systems when needs change. For welded shelving, the value is in its extreme durability—it can provide decades of service in harsh environments with minimal maintenance.

For any business expecting growth or inventory changes, the ability to adapt without buying entirely new systems is a massive long-term financial win. As project deadlines loom, a system that installs quickly can be the difference-maker. Planning ahead lets you take full advantage of our fast shipping and free design services. Contact Us at (800) 326-4403 to get a free quote and layout.

Real-World Applications: Which Shelving Fits Your Needs?

Technical specs are one thing, but making the right investment comes down to real-world performance. The boltless versus welded shelving debate becomes clearer when you consider your specific operational challenges.

Let's walk through a few common scenarios. By exploring these use cases, you can visualize which system makes the most sense in your own facility.

Warehouse and Distribution Centers

Logistics is all about speed and constant change. For high-volume, dynamic pick-and-pack zones with high SKU diversity, boltless shelving is the clear winner. Its biggest strength is the ability to adjust shelf heights on the fly to fit new product sizes without tearing down an entire aisle. This adaptability is critical for maintaining picking efficiency and maximizing space, especially when organizing inventory with storage bins as discussed in our shelving with bins guide.

For bulk storage areas holding heavy, uniform goods, welded shelving provides the raw strength and stability you need. When sheer load capacity is your number one concern and you have no plans to reconfigure, they form the unyielding backbone of your long-term storage strategy.

Retail Stockrooms

Retail inventory shifts dramatically with seasonality. The stockroom must keep up with incoming shipments to support the sales floor.

This is where the quick-change capability of boltless shelving becomes a game-changer. Backrooms are notoriously tight on space. Being able to easily disassemble, move, and rebuild shelving gives managers the power to optimize their layout for different times of the year.

A key advantage in retail is minimizing downtime. The tool-free assembly of boltless shelving means your own team can handle layout changes quickly, without waiting for a specialized crew.

Manufacturing and Automotive Parts Storage

Manufacturing plants and auto service centers store items that are heavy, oddly shaped, and kept in tough conditions. Here, the extreme durability and massive load capacity of welded shelving make it the essential choice for things like heavy tools, dies, and engine blocks. These environments demand a storage solution that can take a beating.

That said, boltless shelving still has a crucial role. For organizing the thousands of smaller, lighter components in a parts department, its adjustability is invaluable. A parts stockroom can be perfectly optimized using boltless systems, just like we see in this case study of a trailer manufacturer's parts stock room. A well-organized and adaptable parts room can make your technicians significantly more efficient. Our team can provide a free layout design to help you plan the perfect combination of shelving. Call (800) 326-4403 to get started.

The Strategic Impact of Your Shelving Investment

When you see shelving as a strategic asset, you unlock serious operational advantages. The choice between boltless and welded shelving isn't just about storage; it's about building an infrastructure that impacts how well your facility can adapt, grow, and stay efficient.

Opting for adaptable boltless shelving is a direct investment in your company's agility. It’s a practical way to future-proof your facility, letting you respond to market shifts or new product lines without the massive downtime and cost of a total overhaul.

Long-Term Stability vs. Future Flexibility

Investing in high-strength welded shelving gives you a permanent, low-maintenance backbone for your core operations. It's a "set it and forget it" solution for mission-critical, heavy inventory where maximum durability is the top priority.

Proactive planning with the right system helps you avoid future bottlenecks and costly reconfiguration delays. The right choice supports your operational flow, whether that means constant re-slotting in e-commerce or fixed-station storage in manufacturing.

When you align your shelving choice with your long-term business goals, you transform a capital expense into a competitive advantage.

Making a Forward-Thinking Decision

At the end of the day, the boltless shelving vs. welded shelving debate is about preparing for your company's future.

- For Businesses Expecting Growth and Change: Boltless shelving offers the lowest risk and highest adaptability. Its modular nature means you won't be locked into a layout that becomes obsolete.

- For Operations with Stable, Heavy-Duty Needs: Welded shelving provides unmatched long-term durability, minimizing replacement costs and ensuring the safety of your heaviest items for decades.

We are increasingly seeing businesses adopt a hybrid approach. Using welded shelving for bulk backstock and boltless systems for active pick areas combines the best of both worlds. Planning for this kind of integrated system now, even if you roll it out in phases, positions your operation for greater efficiency.

Our team specializes in creating these custom layouts, and we offer free designs to help you visualize what's possible. Contact Us or call (800) 326-4403 to start planning.

Conclusion: Let's Build Your Ideal Storage System

You've learned the fundamentals of boltless shelving vs welded shelving. It boils down to this: boltless gives you incredible flexibility and speed, while welded delivers pure, permanent strength. Turning that knowledge into the right storage system for your facility is where the real work begins.

This is the point where a good plan makes all the difference, and it's where we come in. At Material Handling USA, our job starts long before you place an order. We're here to bridge the gap between your decision and a fully operational, high-performing storage area.

Partnering for a Perfect Fit

Picking the right type of shelving is only half the battle. Ensuring it works with your workflow, fits your space, and supports your operation is what separates a good investment from a costly mistake.

That's why our team offers free, no-obligation layout and design services. We take your facility's exact dimensions and operational needs to map out a system that maximizes your footprint. This planning phase is critical—it helps you visualize the final result and avoids expensive errors.

From Design to Delivery

We've built our reputation on competitive pricing, high-quality materials, and the fastest shipping and delivery in the industry. This is our commitment to getting your project running without the delays that plague so many projects.

With the current demand for storage solutions, planning ahead has never been more important. Getting our design team involved early not only results in a better layout but also helps secure your spot in the production queue, helping you avoid frustrating bottlenecks and project delays.

Whether you've settled on an adaptable boltless system for a busy stockroom or a heavy-duty welded solution for industrial parts, our experts are ready to turn your needs into a detailed plan and a firm quote.

Ready to move forward?

- For standard setups, browse our wide selection of boltless shelving components. You can Shop Now and get your order moving.

- For custom layouts or a detailed quote, our specialists are on standby. Request a Quote online or give us a call directly at (800) 326-4403.

Frequently Asked Questions

When deciding between boltless and welded shelving, a few key questions always come up. Managers and buyers need to know about performance, cost, and safety. Let's tackle the most common ones.

Can Boltless Shelving Handle Heavy Loads?

Yes, absolutely. Modern heavy-duty boltless shelving is engineered to support significant weight, often rivaling light or medium-duty welded systems. The final capacity depends on the steel gauge, beam design, and decking you choose. While a fully welded unit is still the champion for extreme industrial use, many boltless systems can hold thousands of pounds per shelf level, making them a rugged choice for most warehouse, commercial, and retail applications.

Is Welded Shelving More Expensive Than Boltless Shelving?

Looking purely at the sticker price, welded shelving often costs more upfront due to more intensive manufacturing. But to get the real picture, you have to look at the total cost of ownership. Boltless shelving saves you significantly on installation labor and offers long-term value through its reconfigurability. Welded shelving pays you back with sheer durability and longevity in tough environments, which can slash replacement costs over decades.

How Do I Choose Shelving for a Seismic Zone?

In a seismic zone, stability is everything. Both types of shelving can be engineered to be compliant, but the approach is different. Welded shelving provides a naturally rigid foundation but still needs proper anchoring and bracing to meet local codes. Boltless systems must be assembled perfectly and usually require extra hardware like seismic footplates and specialized bracing. If you're in a seismic zone, consulting a storage expert is non-negotiable to ensure your system is safe and compliant. Our team can help you navigate these specific engineering needs.

Getting your storage plan right from the start saves you from expensive compliance issues. With demand for properly engineered systems on the rise, finalizing your designs early is the best way to keep your project on schedule.

Material Handling USA offers expert guidance and free, no-obligation layouts to ensure your storage system meets all your operational and safety needs. For versatile and robust options, you can Shop Now at our online store for boltless shelving components. For a personalized plan, Request a Quote or call our specialists at (800) 326-4403.