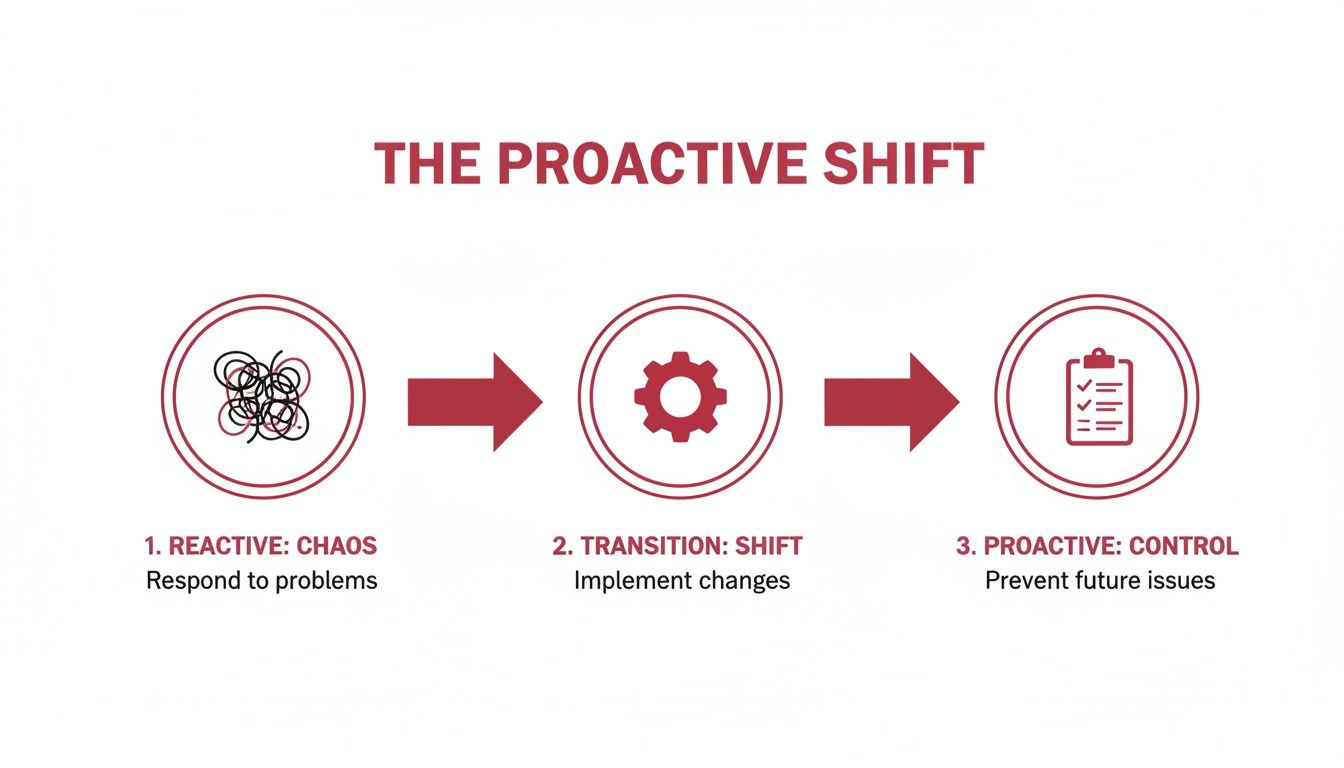

A preventive maintenance schedule is more than just a document; it's a strategic shift away from chaotic, reactive fixes toward a controlled, proactive system. Think of it as a blueprint that details precisely what tasks need doing and when, turning unpredictable repair bills into a manageable investment that keeps your equipment running longer and your facility safer.

Moving from Reactive Repairs to Proactive Reliability

Unplanned equipment downtime isn’t just an inconvenience—it’s a direct hit to your bottom line. Sticking with a "run it till it breaks" approach means your team is constantly putting out fires instead of preventing them. This endless reactive cycle leads to inflated emergency repair bills, costly project delays, and missed production targets that slowly eat away at your profits.

This is where a solid preventive maintenance schedule template becomes your most valuable tool. It’s not just a simple checklist. It's the foundational plan for operational excellence, giving you predictable control over your maintenance budget and the health of your most critical assets.

The True Cost of Reactive Maintenance

Every single minute of unplanned downtime has a price tag. While the repair bill is obvious, the hidden costs often do the most damage. We see it all the time with businesses that haven't made the switch.

These costs typically include:

- Overtime Labor: Emergency repairs don't happen on a 9-to-5 schedule. They often mean calling in technicians after hours or on weekends at premium pay.

- Rush Shipping Fees: When a machine goes down unexpectedly, you need parts now. That usually involves expensive overnight shipping just to get operations back online.

- Production Bottlenecks: A single failure on a key piece of equipment, like a conveyor or packaging line, can bring the entire workflow to a screeching halt, wrecking your fulfillment and delivery timelines.

- Safety Risks: Equipment that isn’t regularly maintained is far more likely to malfunction in a way that creates a hazardous work environment for your team.

Adopting a preventive strategy isn't just about avoiding breakdowns; it's about investing in reliability. This shift gives you the power to schedule maintenance on your own terms, minimizing disruption and maximizing the operational lifespan of every asset in your facility.

A Data Backed Approach to Maintenance

In the fast paced world of warehouse operations and manufacturing, sticking to a solid preventive maintenance schedule is a proven game changer. A striking 67% of manufacturing companies now rely on preventive maintenance as their go-to strategy to tackle machine downtime. On the flip side, facilities without proper schedules often spend over 30 hours a week just reacting to issues.

Understanding the financial impact is critical, and a detailed preventive vs reactive maintenance cost analysis can shine a light on the potential savings. The numbers speak for themselves: every $1 invested in preventive maintenance yields $3 to $5 in savings by dodging those costly emergency repairs.

With a well planned schedule, you can anticipate needs, manage inventory for parts like pallet covers or strapping, and completely avoid the premium costs of last minute orders. The high demand for industrial equipment and current supply chain pressures mean that securing installation timelines is more competitive than ever. By planning your facility's maintenance needs now, you ensure better scheduling and avoid the delays so many other businesses are facing.

Ready to build a more reliable operation? Material Handling USA offers the quality products and free, no obligation layout designs to support your proactive maintenance goals. Request a Quote or call our experts at (800) 326-4403 to get started.

Designing Your Custom Maintenance Template

Let's get down to brass tacks. Building a preventive maintenance schedule that actually works for your facility is all about turning goals into a concrete, actionable plan. Think of it less like a static document and more like a dynamic tool that flexes with your operation's real world demands. A good template ensures your most vital machinery gets the attention it needs, finally shifting your team from reactive firefighting to strategic, planned maintenance.

This is the journey we're talking about—moving from chaotic, last minute repairs to a state of controlled, proactive reliability.

When you make this shift, maintenance activities become planned, predictable, and perfectly aligned with your bigger operational goals. No more surprises.

Start with a Comprehensive Asset Inventory

You can't maintain what you don't know you have. Simple as that. The absolute first step is to build a complete and accurate inventory of all your assets. This list is the foundation your entire PM program will be built on.

For every single piece of equipment, from the main conveyor system down to the pallet wrappers in shipping, you need to capture the key details. This isn't just about jotting down names; it's about creating a detailed profile for every asset that needs a wrench turned on it.

Your inventory should include, at a minimum:

- Asset ID: A unique identifier for easy tracking (e.g., CV-01, DL-03).

- Asset Name & Description: What is it? Be specific. "Conveyor Belt Section B," not just "conveyor."

- Location: Where can we find it? "Dock Leveler Bay 3," for example.

- Make & Model: Absolutely critical for sourcing the right parts and pulling up manuals.

- Serial Number: For warranty claims and specific service bulletins.

- In-Service Date: The day the equipment officially started its life in your facility.

Getting this foundational step right ensures no critical equipment gets missed. It becomes the single source of truth for your maintenance team. Once you have this list, you can figure out what needs your attention most urgently.

Prioritize Equipment with Criticality Analysis

Let's be honest: not all equipment is created equal. A breakdown of your primary sorting conveyor will bring operations to a grinding halt, while a secondary packaging station going down is more of an annoyance. This is where criticality analysis comes in—it helps you point your limited resources where they’ll make the biggest impact.

A straightforward way to do this is to score each asset based on a few key factors:

- Impact on Production: How badly would a failure mess up your output? (Low, Medium, High)

- Impact on Safety: Does a failure create a potential safety hazard? (Low, Medium, High)

- Cost of Repair: How expensive is this thing to fix if it breaks? (Low, Medium, High)

Assets that score "High" across the board are your most critical pieces of machinery. These are the ones that should get the most frequent and thorough maintenance tasks. This risk based approach ensures your PM efforts deliver the biggest bang for your buck by preventing the most catastrophic failures.

Define Maintenance Tasks and Frequencies

With your assets inventoried and prioritized, it’s time to define the what and the when. What specific tasks need to be done, and how often? The best place to start is the Original Equipment Manufacturer (OEM) manual. These guides give you a solid baseline of recommended maintenance activities and schedules designed to keep the equipment running as it should.

For a conveyor system, the OEM might recommend something like this:

- Weekly: Visual inspection of belt tracking and tension.

- Monthly: Lubrication of bearings and rollers.

- Quarterly: Inspection of the motor and gearbox for signs of wear.

- Annually: A comprehensive teardown and inspection of all mechanical and electrical components.

But don't just copy and paste from the manual. OEM recommendations are a starting point, not the final word. You have to tailor these frequencies to your facility's unique conditions. A conveyor running 24/7 in a dusty warehouse is going to need lubrication far more often than one used for a single shift in a cleanroom. Use your team's on the ground experience and historical repair data to fine tune these intervals.

For a deeper dive into maintenance and reliability best practices, check out our MRO Assessment Guide.

Assembling Your Template: The Essential Fields

Okay, it's time to pull all this information together into a structured template. Whether you're using a simple spreadsheet or a sophisticated CMMS, these are the non negotiable fields that will make your schedule functional and easy for everyone to use.

Essential Fields for Your Preventive Maintenance Template

Every solid PM template needs a core set of data points to be effective. Think of this table as your checklist for building a template that works.

| Field Name | Description | Example |

|---|---|---|

| Asset ID | The unique code for the equipment. | CONV-001 |

| Task Description | A clear, concise description of the work. | Lubricate main drive chain. |

| Task Frequency | How often the task should be done. | Monthly |

| Assigned To | The technician or team responsible. | Maintenance Team A |

| Last Completed | The date the task was last performed. | 09/15/2024 |

| Next Due | The calculated next due date. | 10/15/2024 |

| Status | The current status of the task. | Open / In Progress / Completed |

| Notes/Comments | A section for observations or issues. | "Slight chain wear noted." |

Having these fields locked in gives you a clear, at a glance view of your entire maintenance operation, making it easy to track progress and spot potential problems before they escalate.

The data speaks for itself. For managers trying to run lean operations, remember that reactive maintenance costs 3 to 5 times more than preventive maintenance over an asset's lifetime. And with 80% of manufacturing plants already using some form of a PM schedule, falling behind is a choice to accept higher costs and more downtime.

By building a dynamic tool instead of a static document, you empower your team to get ahead of problems. A well designed preventive maintenance schedule is your roadmap to better equipment reliability, a safer workplace, and more control over your budget.

The benefits start stacking up fast. Planning ahead reduces the scramble for emergency parts, which can help lower your spare parts inventory by 15-20%. With the current demand for industrial equipment, securing your maintenance supplies and scheduling work ahead of time is the best way to avoid the project delays hitting everyone else.

Real World Maintenance Schedules in Action

Templates and theory are great starting points, but let's be honest—the real value comes from seeing a preventive maintenance schedule work in the real world. How do these concepts actually hold up in the high stakes, fast paced environment of a modern warehouse or manufacturing plant?

It all comes down to tailoring the schedule to the specific equipment that keeps your operation moving. Let’s get practical and look at some industry specific examples for the assets you rely on every day, from conveyors to pallet racking. This is how a proactive approach keeps your facility humming and your people safe.

E-commerce Warehouse Maintenance Focus

In a bustling e-commerce fulfillment center, uptime is everything. A single hour of conveyor downtime during a peak sales event isn't just an inconvenience; it can mean thousands of missed orders. The PM schedule here needs to be aggressive, frequent, and laser focused on the machinery that moves products.

The workhorses in this environment are your conveyor systems, pallet racking, forklifts, and packaging machines. If any one of them goes down, you've got a massive bottleneck. That’s why the schedule prioritizes constant visual checks and routine servicing.

Here’s what that looks like for a primary conveyor system:

- Daily Tasks (Pre-Shift):

- Visual Inspection: Walk the entire line. You're looking for debris, loose parts, or any obvious damage to the belt or rollers.

- Emergency Stop Test: Physically test every single e-stop. This is a non negotiable safety check that protects your team.

- Weekly Tasks:

- Belt Tracking and Tension: Make sure the conveyor belt is centered and has the right tension. Misalignment is one of the quickest ways to kill a belt.

- Roller Check: Listen for unusual noises. Grinding or squeaking from rollers is a dead giveaway that a bearing is about to fail.

- Monthly Tasks:

- Lubrication: Grab the grease gun and hit all specified bearings and moving parts, following the OEM manual to the letter.

- Motor and Gearbox Inspection: Check the drive components for overheating, strange vibrations, or any signs of fluid leaks.

- Quarterly Tasks:

- Component Inspection: Time for a deeper dive. Closely examine chains, sprockets, and pulleys for signs of wear and tear.

Manufacturing Plant and Pallet Racking Safety

While manufacturing plants and warehouses share some equipment, plants often have unique structures like industrial mezzanines and heavy duty storage. The focus here isn't just uptime—it's about structural integrity and safety, especially when it comes to pallet racking. A racking failure is a catastrophic event, which is why its inspection has to be a top priority.

A solid PM schedule is your key to asset longevity and staying on the right side of OSHA. For a deeper look, check out our detailed article on how to keep warehouse racking safe.

A well documented maintenance history for your racking is not just good practice; it's your best defense in a safety audit. It demonstrates a clear commitment to providing a safe work environment for your team.

The table below breaks down a sample PM schedule for a standard selective pallet rack system in a busy manufacturing environment.

| Frequency | Task Description | Details and Focus Points |

|---|---|---|

| Monthly | Operator Visual Inspection | This is your first line of defense. Train operators to spot and report obvious damage like bent uprights, missing safety pins, or overloaded beams during their daily routines. |

| Quarterly | Detailed Visual Inspection | A trained internal inspector should walk every aisle, specifically looking for damage to frames, beams, and anchors. They need to check for plumbness and ensure load capacity labels are visible and accurate. |

| Annually | Professional Third Party Audit | Bring in an external expert. They'll inspect the entire system for compliance with current safety standards, spot non obvious damage, and provide a formal report with repair recommendations. |

This tiered approach ensures that potential issues are caught early before they can escalate into a major safety hazard or a costly structural failure.

Tailoring Schedules to Your Operation

These examples for conveyors and racking drive home a crucial point: there's no such thing as a "one size fits all" preventive maintenance schedule template. The right schedule for your facility is dictated entirely by your specific equipment, how hard you run it, and the environment it lives in.

As you customize your plan, think about these factors:

- Operating Hours: Equipment running 24/7 is going to need a lot more attention than assets used for a single eight hour shift.

- Environmental Conditions: A dusty, dirty, or corrosive environment accelerates wear on mechanical parts, meaning you'll need shorter service intervals.

- Asset Age: Older machinery naturally requires more frequent checks and proactive part replacements to stay reliable.

Start with the OEM guidelines, but then adjust them based on these real world conditions. That’s how you build a schedule that is both effective and efficient, ensuring you get the most out of your material handling investments. With the current high demand for industrial equipment, planning your maintenance now means you can secure parts and service timelines, avoiding the delays that are catching less prepared businesses off guard.

Ready to equip your facility with reliable, high quality material handling solutions? Material Handling USA offers competitive pricing and the fastest shipping in the industry. Request a Quote today for a free, no obligation layout and design consultation, or call our specialists at (800) 326-4403.

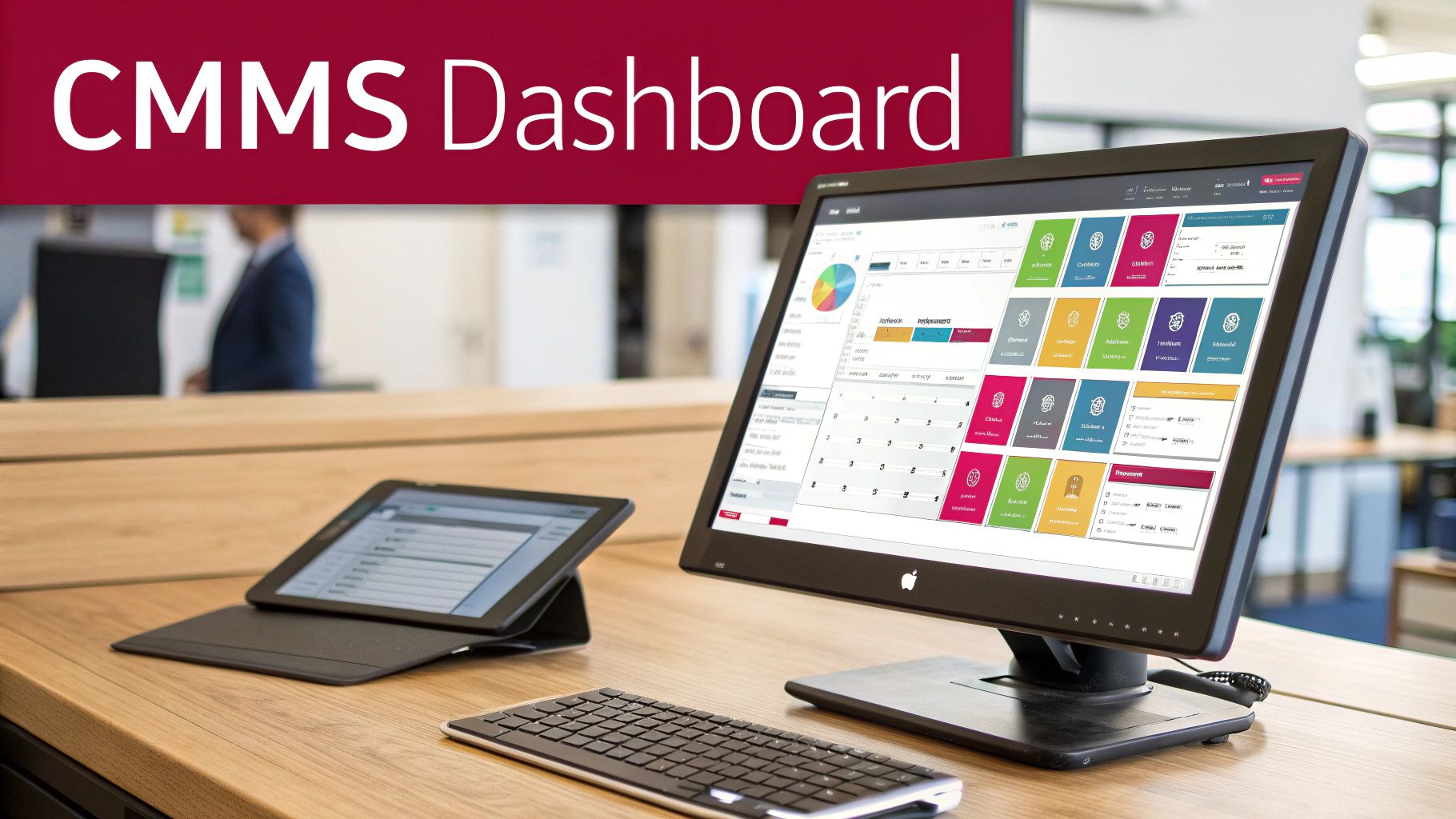

Upgrading Your Schedule with Modern CMMS Tools

That spreadsheet template you've built? It's a fantastic starting point. But when you're ready to stop just managing maintenance and start optimizing it, it's time to talk about technology. Moving from a manual schedule to a Computerized Maintenance Management System (CMMS) is the natural next step for any operation that wants to scale up, work smarter, and make decisions based on real data, not just gut feelings.

A CMMS does more than just put your schedule on a screen; it breathes life into it, turning it into an active, intelligent system. Think of it as the central nervous system for your maintenance team—automating the repetitive stuff, giving you deep insights into equipment health, and creating a smooth, connected workflow.

Key Benefits of a CMMS

Let's be honest, moving beyond spreadsheets unlocks capabilities that directly impact your bottom line. A good CMMS connects your meticulously planned facility layout and asset list to a dynamic scheduling and reporting engine. Suddenly, your maintenance data isn't just a record of what happened; it's a strategic tool for what happens next.

You'll see immediate advantages, like:

- Automated Work Orders: The system automatically spits out and assigns work orders based on your schedules. No more manual tracking, no more "oops, we missed that one" moments.

- Detailed Asset Histories: Every single repair, inspection, and part gets logged against the specific asset. This creates a complete service history that’s invaluable for diagnosing recurring problems and deciding when it’s time to repair versus replace.

- Insightful Performance Analytics: Dashboards give you a quick, at a glance view of your most important metrics. You can track team performance, keep an eye on costs, and finally have the hard data to prove the value of your PM program to the higher ups.

Must Have CMMS Features

Not all CMMS platforms are created equal, and it's easy to get lost in a sea of features. As you start looking, keep your focus on the tools that will deliver the most value right away and grow with you.

Migrating your preventive maintenance schedule template to a CMMS is more than an upgrade—it's an investment in operational intelligence. The right system provides the visibility you need to move from managing maintenance to optimizing it.

At a minimum, you'll want a system that nails these core functions:

| Feature | Why It Matters |

|---|---|

| Work Order Management | This is the heart of any CMMS. The ability to create, assign, prioritize, and track work orders from start to finish is non negotiable. |

| Asset Management | You need a central database to store all the critical info about your equipment, from manuals and schematics to warranty details. |

| Mobile Accessibility | Modern maintenance doesn't happen at a desk. Technicians need robust CMMS mobile apps to update work orders, pull up procedures, and report issues right from the facility floor. |

| Reporting and Analytics | Dashboards and customizable reports are essential for tracking KPIs, spotting trends, and making informed decisions instead of educated guesses. |

For operations also looking to get a better handle on inventory, our Enasys Asset Tracking Software offers powerful features that integrate perfectly with a broader maintenance strategy.

Migrating Your Data Smoothly

I know what you're thinking—moving everything from a spreadsheet to a new system sounds like a headache. But a smooth transition is all about preparation, and that preventive maintenance schedule template you built is the perfect foundation.

Before you start, take the time to clean up and standardize your data. Make sure asset names are consistent, task descriptions are crystal clear, and all the fields you need are filled out. Most CMMS providers make the technical side easy, offering support for bulk data imports using CSV or Excel files.

By investing in a CMMS, you're not just buying software; you're adopting a system for continuous improvement. The data you gather will empower you to fine tune maintenance frequencies, allocate your resources more effectively, and ultimately squeeze more life out of your most critical assets.

With the current high demand for industrial equipment and installation services, facilities with their maintenance data organized in a CMMS are way ahead of the game. They're better positioned to plan for upgrades and lock in favorable timelines. Don't let disorganized data put you at the back of the line.

To discuss how a CMMS can integrate with your facility's layout and equipment, Request a Quote for a free consultation or call us at (800) 326-4403.

How to Know if Your Maintenance Program is Actually Working

So, you’ve rolled out a new preventive maintenance schedule. Things feel better—the phone isn't ringing off the hook with emergency calls, and there's a sense of calm on the floor. But "feeling" isn't a metric that impresses leadership. They want to see the numbers.

This is where you connect the dots. Tracking the right key performance indicators (KPIs) is how you prove that your maintenance efforts are a strategic asset, not just a cost center. It’s about drawing a direct line from your proactive work to tangible business results, like slashing costs and boosting output.

The Metrics That Really Matter

Don't get lost in a sea of data. To get a clear picture of your program’s health, you need to zero in on a few core metrics. These KPIs give you a balanced view of equipment reliability, maintenance efficiency, and the impact on operations. Start here.

- Mean Time Between Failures (MTBF): This is the gold standard for measuring how reliable your assets are. It calculates the average time a piece of equipment runs before it fails. When your MTBF starts climbing, you have concrete proof that your preventive maintenance is doing its job.

- Preventive Maintenance (PM) Compliance: This one’s simple but powerful. It tracks how many of your scheduled PM tasks were actually completed on time. A high compliance rate—ideally 90% or higher—shows that your team is sticking to the plan you've so carefully built.

- Overall Equipment Effectiveness (OEE): If you want the big picture, OEE is your metric. It combines three key factors: availability (uptime), performance (speed), and quality (good parts produced). It answers the ultimate question: "How close are we to perfect production?" Improving your OEE score is a fantastic way to show maintenance's direct impact on the bottom line.

Putting Numbers to the Pavement

Getting these figures doesn't require a data science degree. With the logs from your maintenance team or a CMMS, you can run the calculations with some straightforward formulas.

| KPI | How to Calculate It | Why It's a Game Changer |

|---|---|---|

| MTBF | Total Operational Hours / Number of Failures | Measures the direct impact of your PM work. A rising MTBF means you're extending asset life and preventing costly breakdowns. |

| PM Compliance | (Completed PM Tasks / Scheduled PM Tasks) x 100 | Shows if your team is actually following the schedule. A low score might point to resource issues or scheduling conflicts. |

| OEE | Availability x Performance x Quality | Provides a holistic view of productivity and directly links reliable equipment to increased output and profitability. |

Let the Data Guide Your Next Move

The real power of these KPIs isn't just in tracking them; it's in using them to make smarter decisions. Is the MTBF for your main conveyor system starting to dip? Maybe it’s time to inspect those motors more frequently. Is PM compliance lagging? You might need to adjust technician schedules or invest in better tools.

It's shocking how many facilities still live in a reactive, "firefighting" mode. The annual cost of unplanned downtime in U.S. factories is a staggering $50 billion. A well executed preventive maintenance schedule template is your first line of defense to reclaim that lost productivity. Moving from reactive to preventive tactics can save 12-18% on maintenance costs and extend asset lifespan by 20-40%, creating a massive competitive edge. You can find more insights on how proactive maintenance is reshaping manufacturing over at CAI.

By tracking the right metrics, you stop guessing. You can pinpoint exactly where your maintenance program is winning and identify the areas that need shoring up, making sure your resources always go where they'll make the biggest difference.

Companies that embrace data driven maintenance are simply better prepared for whatever comes next. With demand for industrial equipment and installation services at an all time high, having clear performance data helps you build a rock solid business case for upgrades and secures your spot in line for new projects.

Ready to build a maintenance program that delivers results you can actually measure? Material Handling USA provides the high quality equipment and free, no obligation layout designs you need to succeed. Request a Quote or call our team at (800) 326-4403 to get the conversation started.

Answering Your Top Questions About Preventive Maintenance Schedules

As you start putting these pieces together, a few questions always pop up. Let's tackle some of the most common ones we hear from managers building out their maintenance programs for the first time. Getting these fundamentals right builds a ton of confidence in your new strategy.

How Do I Figure Out the Right Maintenance Frequency?

This is the million dollar question, isn't it? Your first stop should always be the manufacturer's recommendations in the equipment's owner's manual. Think of that as your baseline—a solid, conservative starting point.

But you can't stop there. You have to tailor that frequency to your real world environment. A forklift running 24/7 in a dusty warehouse will need a much more aggressive PM schedule than the exact same model that only runs a few hours a day in a clean, climate controlled facility. Consider daily usage hours, operating conditions, and especially your own historical failure data.

Pro Tip: For your most critical assets, it's always better to start with a more frequent schedule. You can always dial it back later as you collect performance data. It’s far easier to reduce the frequency than it is to recover from an unexpected failure.

What's the Real Difference Between Preventive and Predictive Maintenance?

It's easy to get these two mixed up, but the distinction is critical.

Preventive Maintenance (PM) is all about the calendar or the hour meter. It’s time based or usage based. We perform a task at a set interval—every month, every quarter, or after every 1,000 hours of operation, no matter what.

Predictive Maintenance (PdM) is condition based. It uses technology like sensors for vibration analysis or thermal imaging to monitor an asset's health in real time. Instead of just guessing, it predicts when a failure is likely to happen, triggering maintenance only when it’s genuinely needed.

Most world class maintenance programs start with a rock solid PM foundation and then layer in PdM for their most critical, high cost assets where the extra investment makes sense.

Can I Really Just Start with a Spreadsheet for My PM Schedule?

Absolutely. In fact, we highly recommend it. For smaller operations or anyone just dipping their toes into formalizing a maintenance plan, a spreadsheet is the perfect place to start. It forces you to build the foundational data you need—asset lists, task details, and frequencies—without the complexity of a new software system.

As your operation grows and you have more assets to track, you'll likely want to migrate that data into a dedicated CMMS to get the benefits of automation, work order tracking, and better reporting. Our free templates are designed to be that perfect first step, setting you up for a smooth transition when the time is right.

Conclusion: Build a More Reliable Operation

Moving from a reactive, chaotic repair cycle to a planned, proactive strategy is one of the smartest investments a facility manager can make. It's not just about avoiding breakdowns; it's about gaining control over your budget, extending the life of your critical assets, and creating a safer, more productive workplace. By building a detailed preventive maintenance schedule template, prioritizing equipment, and tracking your performance, you can turn your maintenance department from a cost center into a powerful competitive advantage.

At Material Handling USA, we’ve seen firsthand how a reliable facility is built on a foundation of quality equipment and strategic planning. With the current high demand for industrial products, planning ahead with a solid maintenance schedule is the smartest way to secure faster installs and avoid the project delays that are hitting less prepared businesses. Don't wait for a breakdown to force your hand.

Take the first step towards a more proactive, cost effective operation. Contact Us for a free, no obligation layout design, or call our team of experts directly at (800) 326-4403 to talk about what your facility needs to thrive.