Explore Custom Solutions Today!

Upgrade Your Tool Storage – Invest in an automotive rolling tool cart and transform your workshop into an organized, efficient workspace.

Home | Automotive Supplies | Labeling & Bin Location Systems for Efficient Parts Rooms

The definitive guide to creating a logical, accurate, and efficient parts identification and tracking system for your workshop.

A well-designed parts room with the best storage equipment can still fail if staff cannot find what they need quickly and accurately. A systematic labeling and location system is the language that connects your inventory, your staff, and your management software. Without it, picking parts becomes a slow process of guesswork, inventory counts are unreliable, and technician productivity plummets. Implementing a clear, consistent system for bin labeling and location tracking is not an administrative task—it is a foundational element of a profitable service operation. This guide will walk you through the core principles of creating a system that eliminates errors, speeds up workflow, and provides perfect inventory visibility.

Upgrade Your Tool Storage – Invest in an automotive rolling tool cart and transform your workshop into an organized, efficient workspace.

From physical labels to digital tracking, every element plays a crucial role.

Before a single label is printed, you must create a logical map of your parts room. A hierarchical naming convention is the industry standard. This system gives every single storage location a unique, intuitive address. A common format is Aisle-Bay-Shelf-Bin. For example, a location code like **A01-03-B-05** would instantly tell a parts professional to go to Aisle 1, Bay 3, Shelf B (the second from the bottom), and Bin 5.

This system must be applied consistently across all storage types, from standard automotive shelving to high-density drawers. The key is to make it scalable and easy for new employees to understand. Aisles should be clearly marked with large signs, and each bay or section should have a visible number. This structured address system is the foundation upon which all picking, put-away, and cycle counting processes are built. It eliminates ambiguity and is the first step in a successful automotive parts room design.

The physical label is the primary interface for your staff. It must be clear, durable, and contain the right information. A good bin label should include the location code, the part number, a brief part description, and, most importantly, a barcode. Using a high-quality industrial label printer and durable label stock is essential to prevent fading, peeling, or smudging.

For commercial and fleet operations, incorporating **VMRS (Vehicle Maintenance Reporting Standards)** codes is a best practice. VMRS is a universal coding system that standardizes the identification of parts and maintenance tasks. Using VMRS codes on your labels creates a common language that is understood across the industry, which is invaluable for managing mixed fleets and integrating with advanced maintenance software. You can learn more about this in our comprehensive guide to storing auto parts.

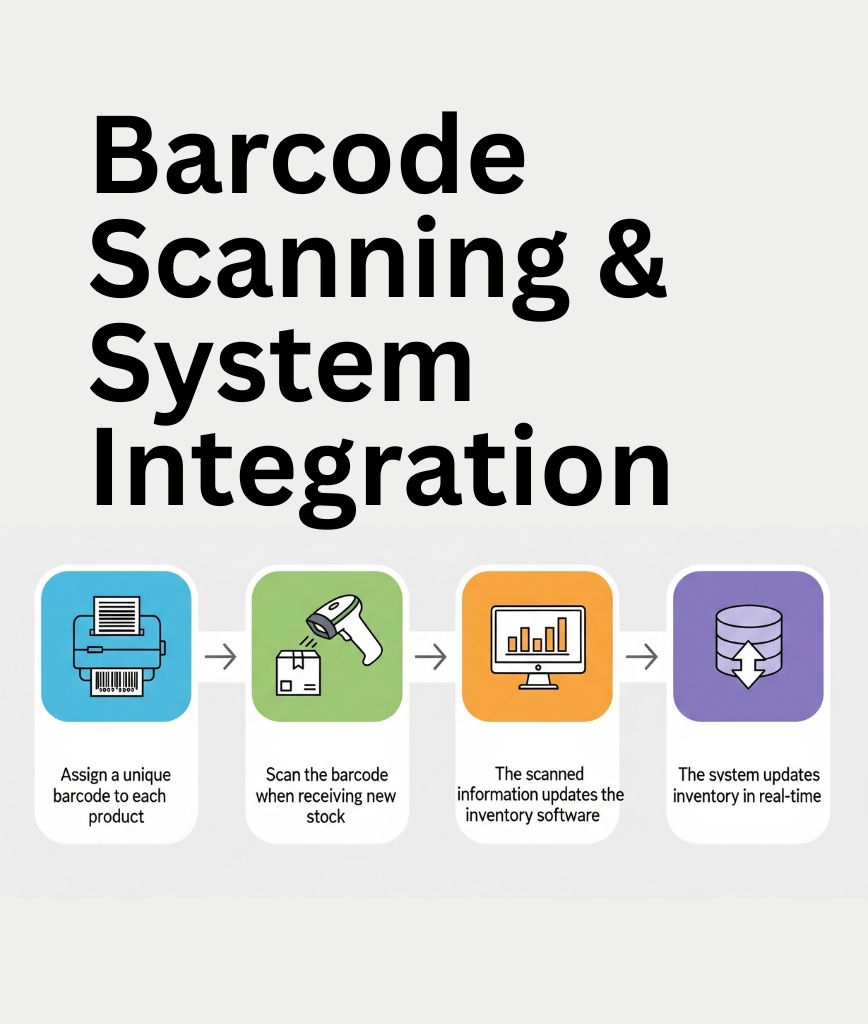

A labeling system realizes its full potential when integrated with barcode scanning and your inventory management software (DMS or WMS). By placing barcodes on both the bin locations and the parts themselves, you create a closed-loop system that ensures accuracy. When a part is picked, the employee scans the bin location and then scans the part. The system instantly verifies that the correct item was pulled, eliminating picking errors.

This technology transforms inventory management. Put-away becomes faster and more accurate. Cycle counting can be done with a handheld scanner instead of a manual checklist, reducing time and errors. This level of real-time data visibility is critical for lean inventory practices and can be further enhanced with automated storage systems that integrate directly with your software. For mobile tasks, equipping staff with rolling tool carts that have a scanner and tablet mount can create highly efficient mobile workstations.

Explore our expert design services and see how the right system can transform your operation.

How clear identification drives tangible business results.

Barcode verification ensures the right part is picked every time, eliminating costly rework and customer dissatisfaction.

A logical location system and clear labels allow staff to find parts in seconds, not minutes, boosting technician productivity.

Real-time tracking through scanning provides a precise, up-to-the-minute view of your inventory, improving ordering and reducing carrying costs.

An intuitive system makes it easy for new hires to become proficient quickly, reducing the training burden on senior staff.

At a minimum, every bin label needs four key pieces of information: the unique location code (e.g., A01-03-B-05), the primary part number, a concise description of the part (e.g., “OIL FILTER V6”), and a scannable barcode that corresponds to the location or part number. Anything less than this will create inefficiency.

For very small parts like fasteners, sensors, and clips, the best practice is to use high-density storage like automotive modular drawers. Each small compartment within the drawer gets its own label. You do not label the individual parts, but rather the compartment that holds them. The drawer itself should have a primary location label, and each compartment within it has a sub-location label.

The first step is always to clean and organize. Before you can label anything, you need to sort your inventory. Dedicate time to go through your entire stock, discard obsolete parts, and group similar items together. Once you have a clean slate, you can begin the process of creating your location naming convention and mapping out where each part category will live. Do not try to label a disorganized space; organize first, then label.