Get a Project Quote

Ready to start? Provide your project details, and our team will deliver a comprehensive quote.

Deploy flexible, scalable, and rapidly-built modular facilities for seasonal peaks, temporary projects, or expansion.

In today’s fast-paced market, business opportunities and operational demands can change in an instant. A sudden surge in demand, a short-term project, or a new market entry requires you to have space and infrastructure ready to go. The traditional approach of building a permanent facility or signing a long-term lease is slow, expensive, and locks you into a fixed footprint that may not match your needs next year, or even next quarter. This lack of agility is a significant business risk, forcing you to either miss opportunities or carry the high cost of underutilized space.

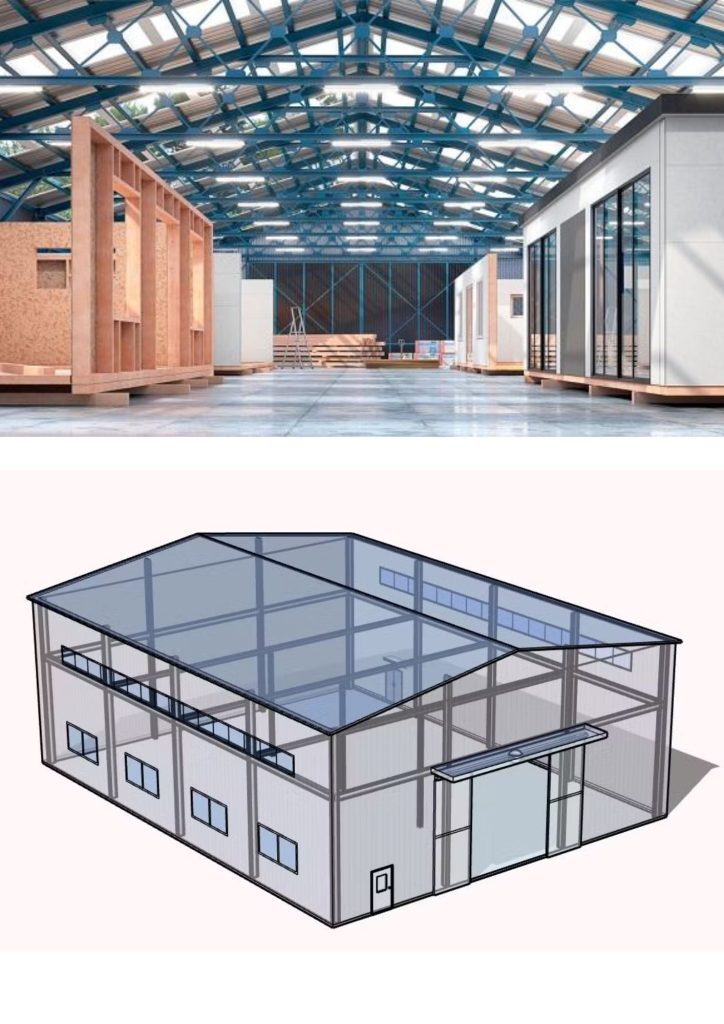

Modular warehouse design offers a strategic alternative. It is an agile approach to infrastructure that allows you to deploy high-quality, fully functional warehouse space in a fraction of the time and cost of traditional construction. These are not flimsy tents; they are engineered structures designed for operational rigor, safety, and efficiency. This methodology allows you to match your physical capacity directly to your current business needs, giving you an unprecedented level of flexibility.

We specialize in designing and deploying modular warehouse solutions that empower your business to be nimble and responsive. Whether you need to manage a seasonal inventory peak, set up a forward distribution point for a specific project, or test a new geographic market, we provide a full warehouse design solution that is built for change. This is about transforming your physical infrastructure from a fixed liability into a flexible, strategic asset.

Ready to start? Provide your project details, and our team will deliver a comprehensive quote.

The single greatest benefit of a modular approach is the speed at which you can have a fully operational facility. While traditional construction can take many months or even years from groundbreaking to launch, a modular warehouse can be designed, fabricated, and installed in a matter of weeks. This speed is a powerful competitive advantage, enabling you to capture fleeting market opportunities and respond to unexpected surges in demand with confidence.

The process is streamlined because the majority of the construction happens off-site in a controlled factory environment. This parallel processing—where the site is being prepared while the building components are being manufactured—dramatically compresses the project timeline. When the components arrive on-site, installation is a process of assembly, not construction, which is faster, safer, and less susceptible to weather delays. This rapid deployment is essential for any business that needs to achieve warehouse automation for next-day delivery capabilities quickly.

This speed does not come at the expense of quality. An intelligent warehouse design is at the heart of every modular project. We work with you to plan the optimal workflow, traffic patterns, and storage systems before a single component is built. This ensures that your rapidly deployed facility is also a highly efficient and productive one from day one.

Have questions? Schedule a no-obligation consultation with a modular construction expert.

The “modular” in modular design refers to more than just the construction method; it defines the operational philosophy of the building itself. These facilities are designed to be easily expanded, contracted, or reconfigured as your business needs evolve. This inherent flexibility is impossible to achieve with a conventional building and is a key driver of long-term cost savings and operational agility.

Imagine your business lands a new contract that requires 50,000 square feet of additional space for one year. With a modular design, you can add a new section to your existing facility to handle the project and then remove it once the contract is complete. This allows you to scale your operating expenses in direct proportion to your revenue. The internal layout is just as flexible. Using modular warehouse shelving and racks, you can quickly reconfigure your storage to accommodate different product types, from standard pallets to specialized inventory like pool and hot tub supplies.

This approach to warehouse optimization means you are never paying for more space than you need. It allows you to build the facility you need today, with the full confidence that it can be adapted for whatever you need tomorrow. This makes a modular design an incredibly smart investment worthy for the long term.

See real-world examples of how we’ve helped businesses like yours quickly deploy effective, safe, and scalable warehouse solutions.

A common misconception is that modular or temporary structures are less safe or durable than permanent buildings. This is simply not the case. Our modular warehouse facilities are engineered to meet or exceed all local building codes and industry safety standards. They are constructed from high-quality, industrial-grade materials and are designed to withstand the same environmental loads, such as wind and snow, as conventional buildings.

The safety of your team and inventory is our top priority. The interior of the facility is designed with the same rigor as any permanent structure. We design clear traffic lanes, install robust warehouse rack protectors, and follow all essential pallet rack safety guidelines. We also engineer for comprehensive warehouse fire safety and ensure that all storage systems are installed correctly to keep your warehouse racking safe.

From the foundation to the roof, and with every rack and workstation in between, a modular warehouse is a robust and secure operational environment. You gain the flexibility and speed of a modular solution without making any compromises on the safety and integrity of your facility. This commitment to safety is a core part of how we improve warehouse safety and productivity.

Provide us with your basic requirements (size, location), and we’ll deliver a preliminary budget and an estimated timeline for your modular warehouse project.

Choosing a modular approach provides a powerful combination of financial and operational benefits that are perfectly suited to a dynamic business environment.

Go from concept to fully operational in a fraction of the time of traditional construction, allowing you to seize opportunities faster.

The streamlined construction process and reduced labor requirements often make modular facilities more cost-effective to build.

Easily expand, shrink, or relocate your facility as your business needs change, ensuring your infrastructure is always the right size.

A modular building can often be classified as equipment, offering potential tax advantages and leasing options not available with permanent real estate.

Off-site manufacturing in a controlled environment minimizes the risk of weather delays and other common on-site construction problems, leading to more reliable project schedules.

While every project is different, a typical timeline from final design approval to a fully assembled structure can be as short as 8-12 weeks, compared to 12-18 months for traditional construction.

Absolutely. Our modular structures are engineered for longevity and can be used as permanent facilities. They are built with high-grade steel and durable cladding designed to last for decades.

Yes. We can fully insulate the structures and integrate industrial-grade HVAC systems to provide temperature and humidity control for sensitive inventory.

That’s the beauty of modular design. The structure can be disassembled and relocated to a new site, or it can be sold. The components are designed for reuse, making it a sustainable choice.

Foundation requirements depend on the size of the structure and local soil conditions, but they are often less extensive than for a conventional building. Options can range from a simple concrete slab to pier foundations.