Get a Project Quote

Ready to start? Provide your project details, and our team will deliver a comprehensive quote.

Apply Lean principles to systematically eliminate waste in motion, transportation, and waiting for a frictionless workflow.

In any warehouse, hidden waste erodes profitability and efficiency. This waste isn’t just about scrap material; it’s found in every unnecessary step a worker takes, every moment a forklift waits for a clear aisle, and every extra foot a product travels before it ships. These small inefficiencies compound into significant operational bottlenecks, driving up labor costs, extending order lead times, and creating a chaotic work environment. The traditional approach of adding more labor or equipment often just adds more complexity to a broken process.

A Lean warehouse design confronts this waste head-on. It is a systematic methodology for creating a physical environment that is inherently efficient. By applying core Lean principles, we analyze your entire value stream—from the moment goods arrive at your receiving dock to the moment they are loaded for shipment—to identify and eliminate non-value-added activities. The goal is to create a state of continuous flow, where products and people move purposefully, without interruption or delay.

This is not a one-size-fits-all solution. It is a rigorous, data-driven process of warehouse optimization that aligns your physical layout with your operational reality. We design facilities where the most efficient path is also the most intuitive and safest path, transforming your warehouse from a source of frustration into a model of operational excellence.

Ready to start? Provide your project details, and our team will deliver a comprehensive quote.

The first step in any Lean transformation is to learn to see the waste that is hiding in plain sight. In a warehouse context, the eight wastes of Lean (often remembered by the acronym DOWNTIME) are the primary targets for elimination through intelligent design. A well-designed layout is your most powerful tool for systematically removing this operational friction.

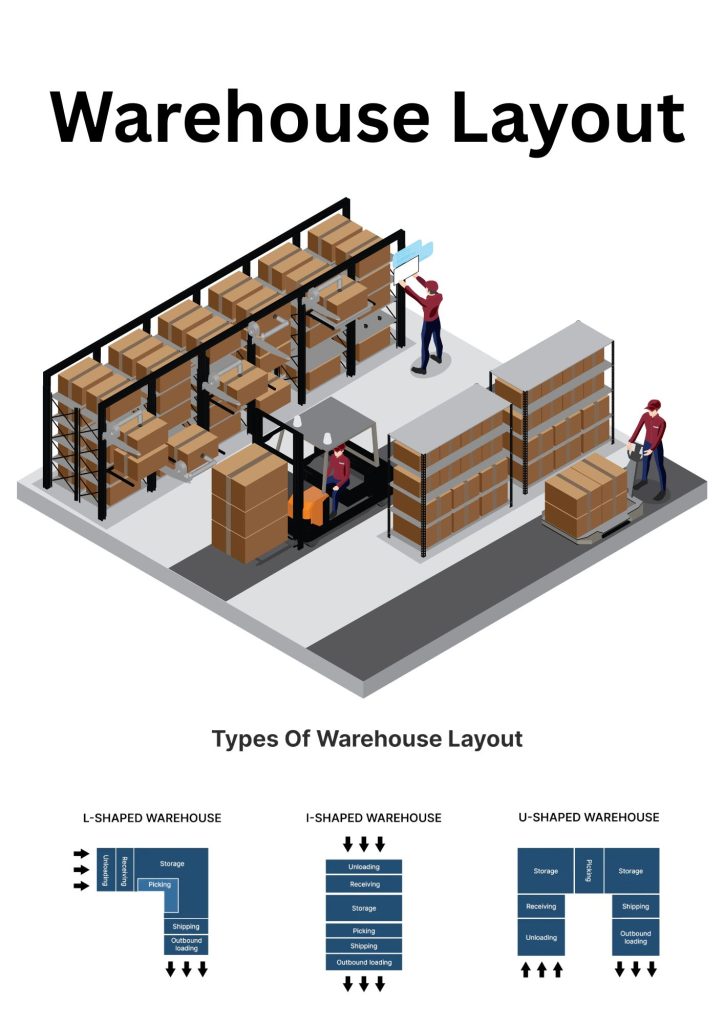

Transportation: Every time a product is moved, it costs time and money without adding value. A Lean layout minimizes this by creating a direct, linear flow from receiving to putaway, picking, packing, and shipping. We analyze your product velocity to co-locate items that are frequently ordered together, drastically reducing the travel distance required to fulfill an order. This is a core tenet of an intelligent warehouse design.

Motion: This refers to the unnecessary movement of people. A poorly organized pick area or packing station forces workers to walk, bend, and reach excessively. We design ergonomic workstations and slotting strategies that place the most frequent picks in the “golden zone” (between the shoulders and knees), reducing physical strain and improving pick times.

Waiting: This is one of the most visible forms of waste. Forklifts waiting for cross-traffic to clear, pickers waiting for product replenishment, or orders piling up at a congested packing station are all symptoms of a poor layout. We design clear, dedicated traffic lanes and balanced workflows to ensure a smooth, continuous pace of work.

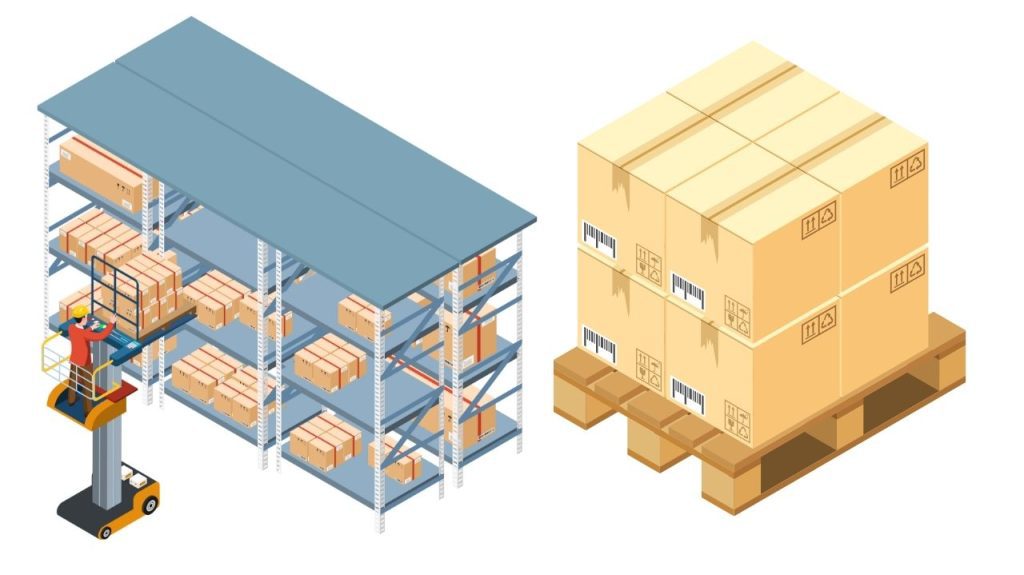

Inventory: Excess inventory hides other problems and ties up capital. A Lean design uses storage solutions like tailored shelving and just-in-time principles to maximize space and improve visibility, making it easier to manage inventory levels effectively.

Defects, Over-Processing, and Overproduction: While often process-related, the layout can contribute to these wastes. A confusing layout can lead to picking errors (defects). A well-organized facility, guided by a step-by-step design guide, simplifies processes and reduces the chance of error.

Have questions? Schedule a no-obligation consultation with a modular construction expert.

Once you can see the waste, the next step is to design a physical workflow that prevents it from occurring. This is achieved by mapping your entire value stream and creating a layout that supports a smooth, uninterrupted flow of materials and information. The ideal is “one-piece flow,” where a single order moves through the entire fulfillment process without stopping.

This often results in a U-shaped or linear flow path. In a U-shaped layout, the receiving and shipping docks are located on the same side of the building. Goods flow in a logical sequence around the facility—from receiving to storage, picking, packing, and finally to shipping—minimizing overall travel distance. This design also improves communication and supervision, as the start and end points of the process are co-located. This is a key part of a full warehouse design solution.

The layout of storage media is also critical to flow. Using the right mix of pallet racking for bulk goods and carton flow racks for high-velocity, each-pick items creates efficient pick faces and supports FIFO (First-In, First-Out) principles. For ultimate flow, integrating automation like conveyors or ASRS can create a seamless goods-to-person system, which is essential for operations focused on next-day delivery.

Whether you need to outfit a new facility or upgrade your existing storage, we can provide a competitive quote for high-quality racking and shelving solutions.

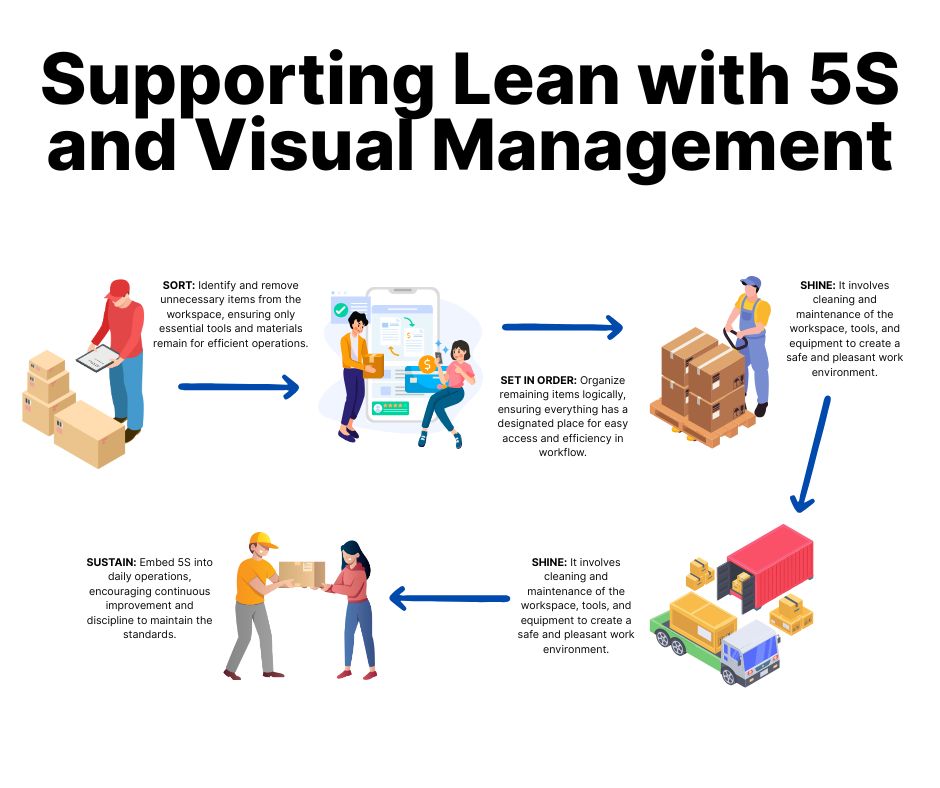

A Lean layout is not just efficient; it is also intuitive. The principles of 5S (Sort, Set in Order, Shine, Standardize, Sustain) and visual management are built directly into the physical design to create a self-managing and self-improving environment. A well-organized space is inherently safer and more productive.

This 5S principle is the very essence of Lean layout design. It means creating a designated, logical home for everything—tools, equipment, and inventory. A good layout is a vital tool for warehouse organization and safety.

The layout itself helps to standardize work. When all workstations are designed ergonomically and equipped identically, processes become repeatable and predictable. Clear floor markings for traffic lanes, storage locations, and work-in-progress (WIP) areas create visual standards that everyone can follow.

A Lean warehouse uses visual cues to communicate information without the need for words or computers. This includes color-coded floor lines, clear signage, and strategically placed Andon lights to signal problems. Safety is also visually reinforced through the use of warehouse rack protectors and guardrails, which provide clear visual boundaries. Adhering to essential pallet rack safety guidelines is a critical part of this visual and physical standardization.

This visual approach helps to improve warehouse safety and productivity by making the status of the operation visible at a glance.

Learn more about how we design and implement the physical infrastructure required to support advanced warehouse automation.

Adopting a Lean approach to your warehouse design is an investment in operational excellence that delivers clear, measurable results.

A well-organized, standardized environment with visual controls drastically reduces the opportunity for human error, leading to higher order accuracy.

Minimizing travel distance for people and equipment reduces labor hours and lowers fuel and maintenance costs. Improved accuracy also reduces the high cost of returns.

A frictionless workflow means orders move from received to shipped in less time, allowing you to meet and exceed customer expectations.

An ergonomic, intuitive, and uncluttered workspace is inherently safer. A less frustrating work environment also leads to higher employee engagement and retention. This makes your investment worthy for the long term.

No. While easiest to implement in a new build, Lean principles are highly effective for retrofitting existing facilities. We can re-engineer your current space to eliminate bottlenecks and dramatically improve flow.

Absolutely. In fact, the more complex the process, the more opportunities there are to simplify and remove waste. A Lean design is about managing complexity through intelligent organization.

Not necessarily. Lean is about optimizing the process first. While automation can certainly support a Lean workflow, the principles of eliminating waste in motion and transportation apply equally to manual and automated environments.

Safety is a core component of Lean. A well-organized, uncluttered space with clear traffic flows and standardized work is inherently safer. We design every layout to meet or exceed all standards for keeping warehouse racking safe and ensuring warehouse fire safety.

Success is measured with clear KPIs. We help you establish baseline metrics before the project—such as order lead time, picks per hour, and travel distance per order—and measure the improvement after implementation.